Piston channel engine

An engine and piston technology, applied in the field of piston engines, can solve the problems of large flow resistance, large impact of clearance volume, and high consumption of throttling loss, so as to reduce flow resistance and throttling loss, be easy to implement, and increase displacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

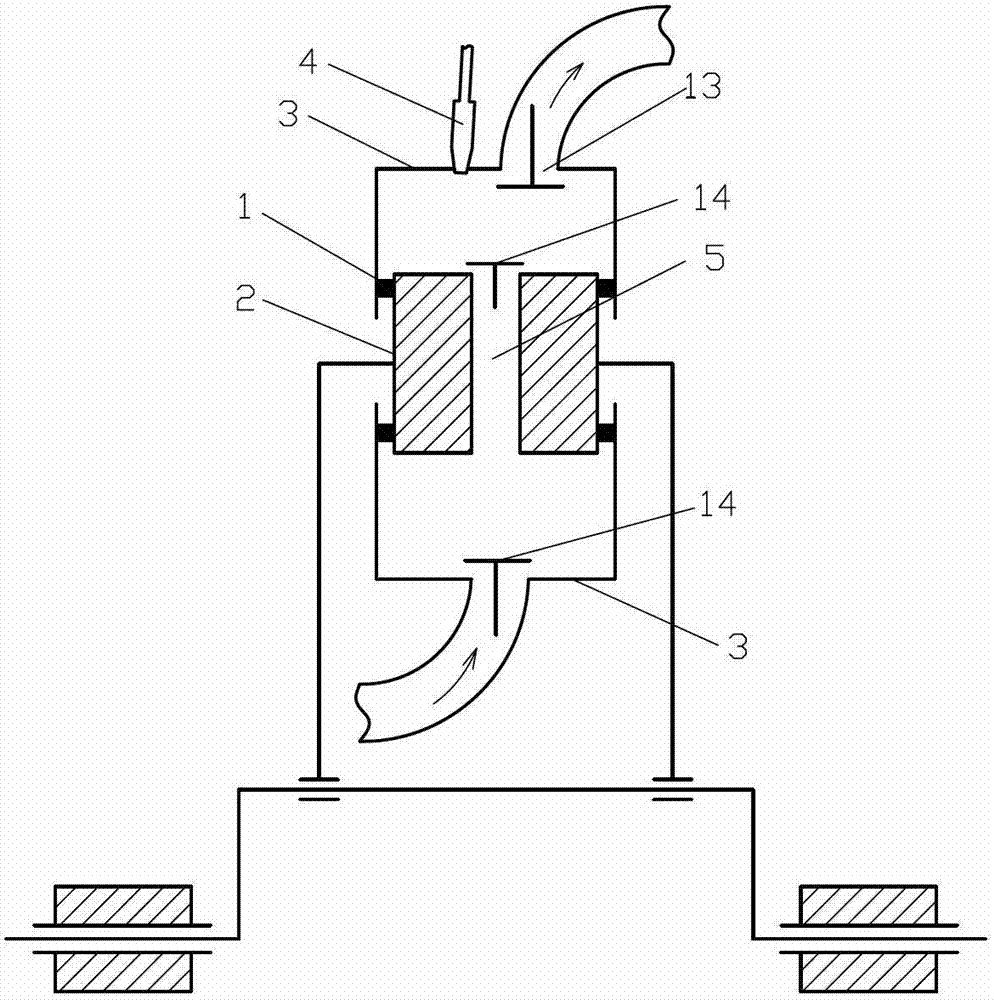

[0031] Such as figure 1 The shown piston channel engine comprises a cylinder 1 and a laterally connected piston 2, the cylinder 1 is matched with the laterally connected piston 2, and a cylinder head 3 is provided at both ends of the cylinder 1, and the cylinder head 3 A cylinder head valve is provided on the cylinder head, and the cylinder head valve includes an intake valve 14 and an exhaust valve 13 respectively arranged on the two cylinder heads 3, and the cylinder head 3 provided with the exhaust valve 13 A fuel inlet 4 is provided on the side connecting piston 2, and a channel 5 communicating with its two ends is provided on the side connecting piston 2, and a piston valve valve is provided on the channel 5, wherein the piston valve valve is set as an intake valve 14; Said lateral connection piston 2 is rotatably connected with the connecting rod journal of the crankshaft through the connecting rod.

[0032] The piston tunnel engine described in this embodiment can wor...

Embodiment 2

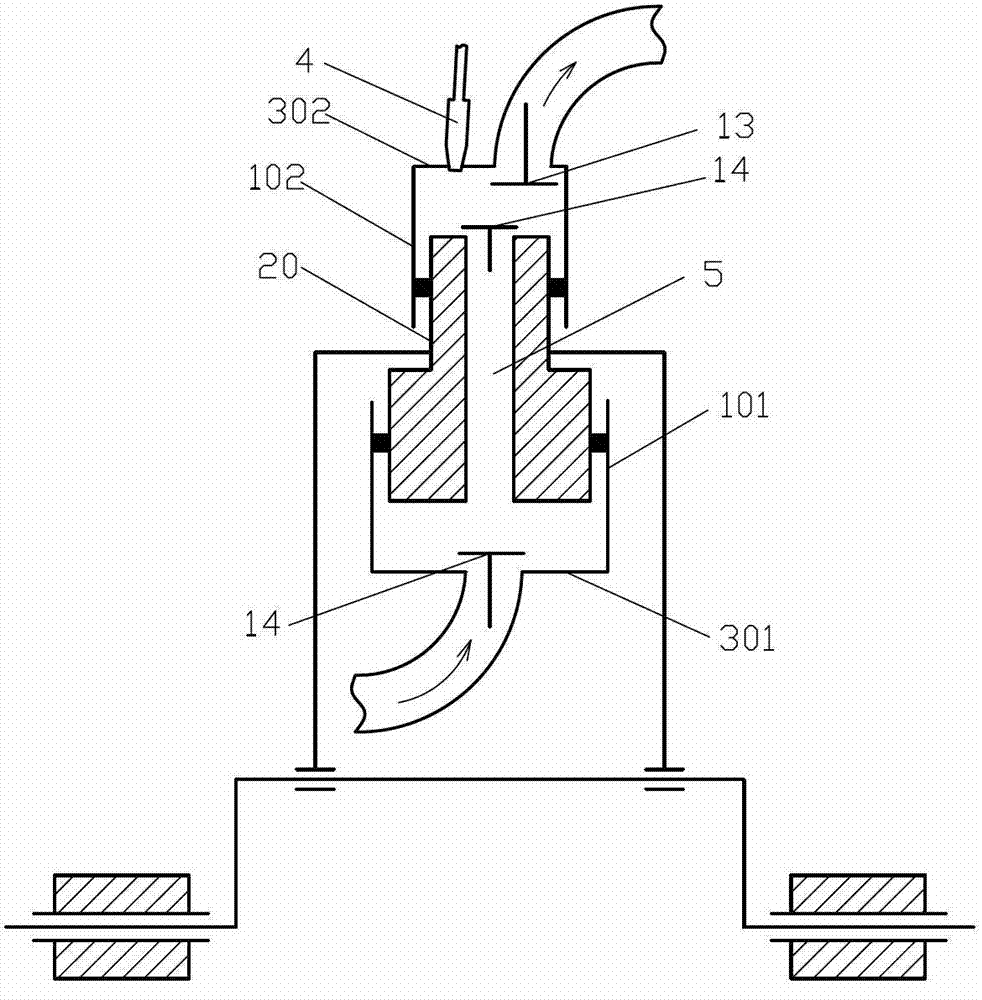

[0035] Such as figure 2 The shown piston tunnel engine comprises a large-diameter cylinder 101, a small-diameter cylinder 102 and a double-diameter laterally connected piston 20, the large-diameter cylinder 101 is matched with the large-diameter section of the dual-diameter laterally connected piston 20, and the The small-diameter cylinder 102 cooperates with the small-diameter section of the double-diameter side connecting piston 20, and a large-diameter cylinder head 301 is arranged at the end of the large-diameter cylinder 101, and a small-diameter cylinder head 302 is established at the end of the small-diameter cylinder 102, A cylinder head distribution valve is set on the large-diameter cylinder head 301, a cylinder head distribution valve and a fuel inlet 4 are set on the small-diameter cylinder head 302, and a passage connecting the two ends of the double-diameter lateral connecting piston 20 is provided. 5. The passage 5 is provided with a piston valve, wherein the c...

Embodiment 3

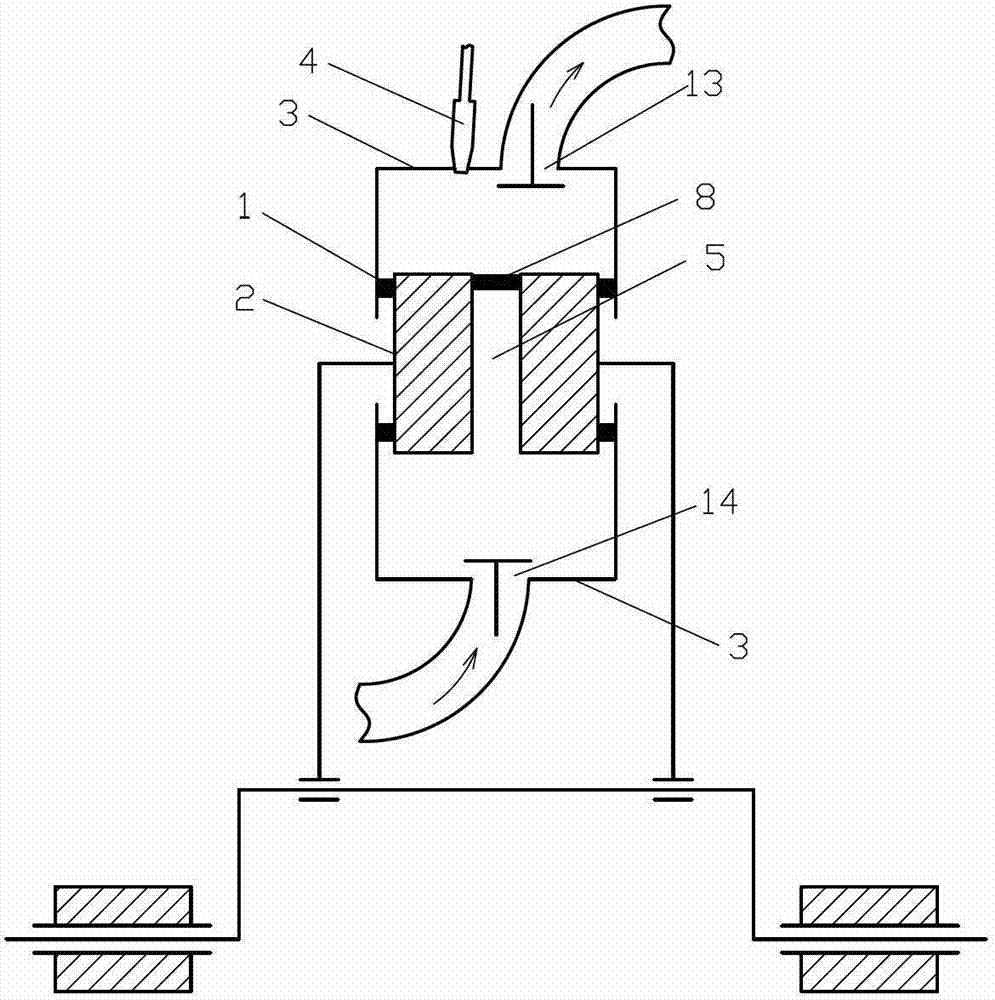

[0039] Such as image 3The difference between the shown piston channel engine and Embodiment 1 is that the piston valve is set as a check valve 8, and the flow direction of the check valve 8 is provided by the cylinder provided with the intake valve 14. One end of the cover 3 flows to one end of the cylinder head 3 where the exhaust valve 13 and the fuel inlet 4 are provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com