Heat exchanger suitable for jet heating technology

A heat exchanger and technology, which is applied in the field of continuous heat treatment of cold-rolled strip steel, can solve the problems of low residual heat energy of exhaust gas, large pressure and heat loss, and limited amount of waste heat recovery, so as to reduce heat and resistance loss and reduce pipelines. The effect of connecting and reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

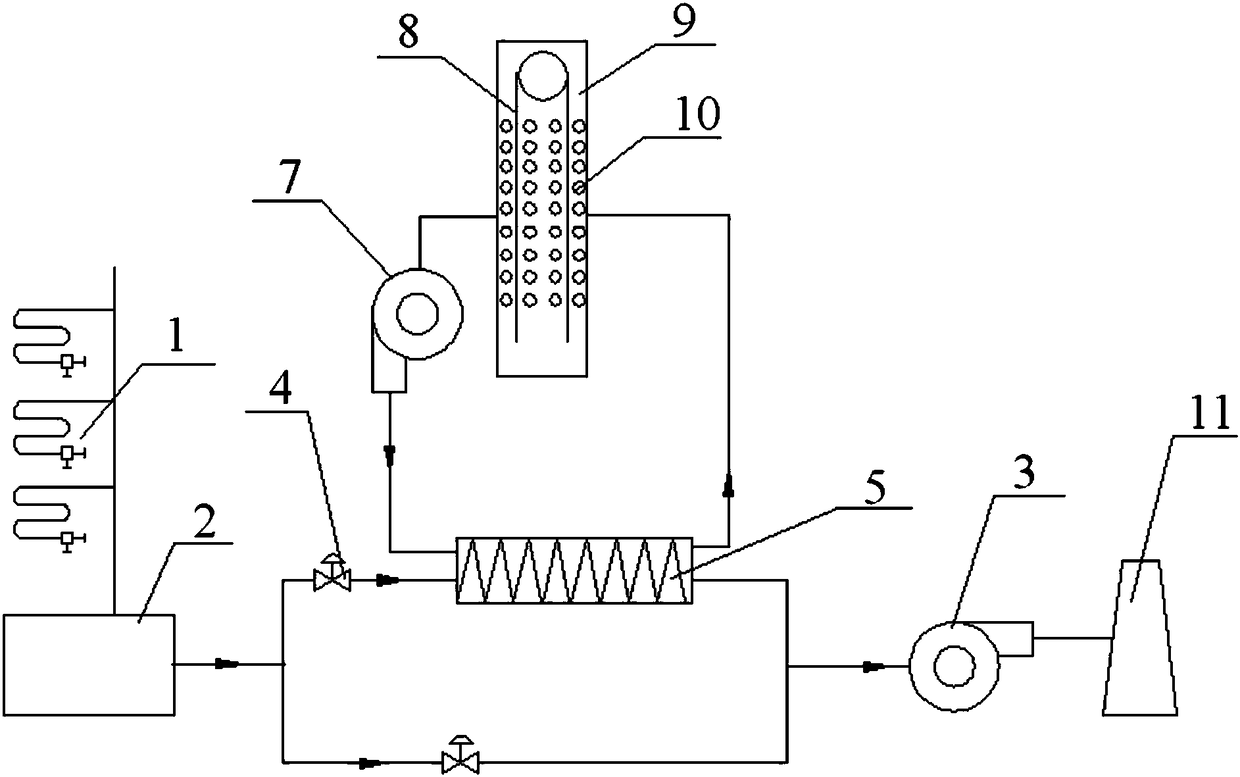

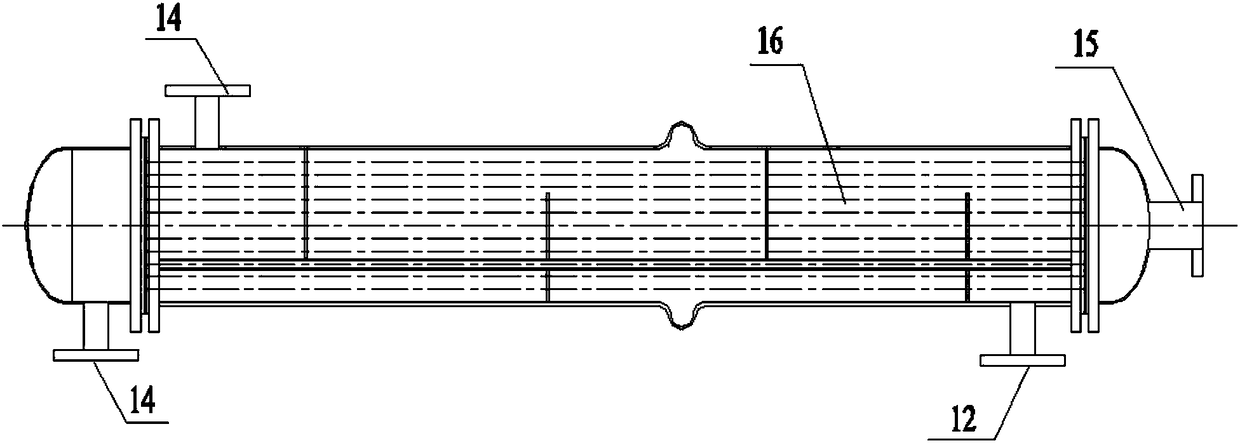

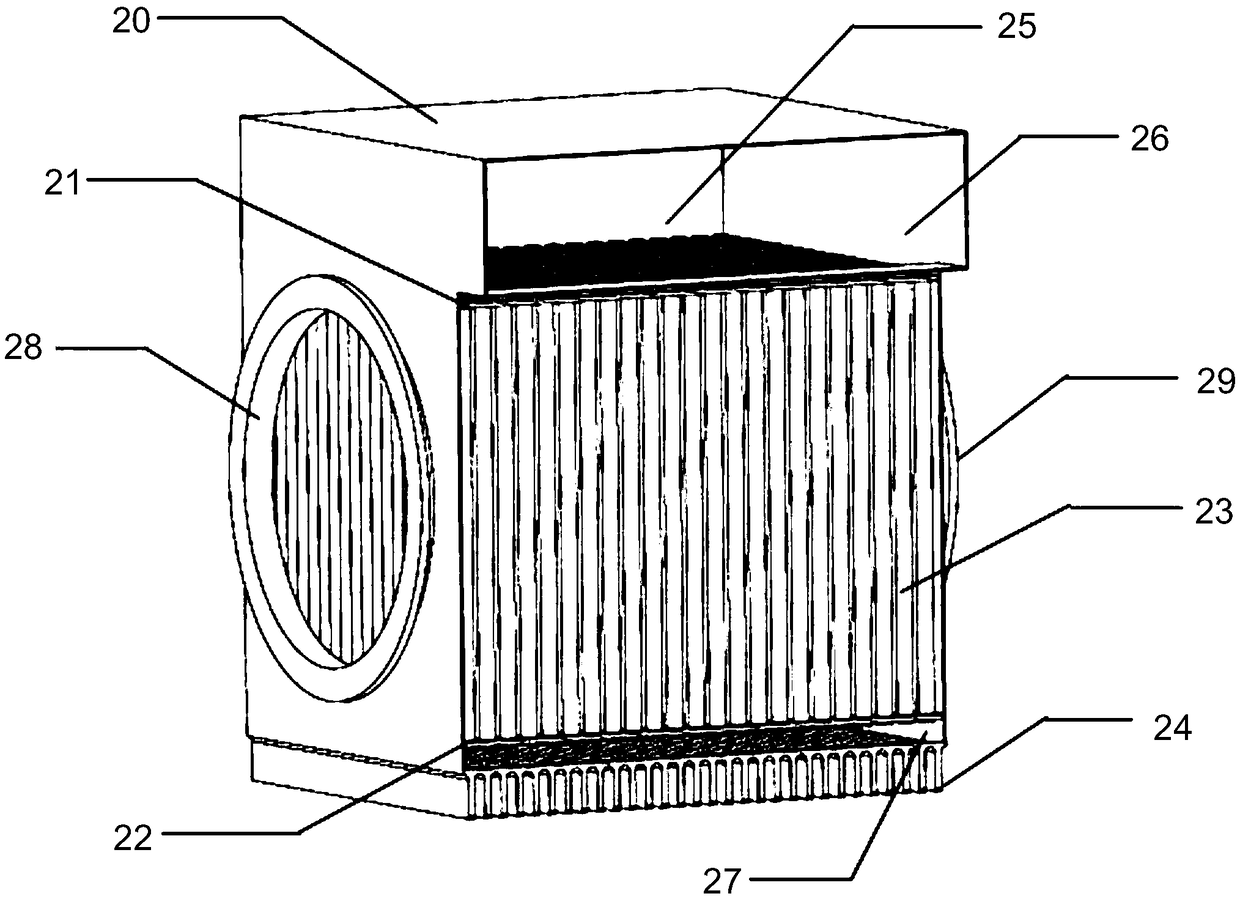

[0028] Please combine Figure 3 to Figure 7 As shown, the present invention provides a heat exchanger suitable for jet heating technology. The heat exchanger is built into the furnace body of the preheating section, and is designed as an integration with the jet wind box of the preheating section, which can greatly shorten the The pipeline in the preheating section improves the thermal efficiency of the comprehensive utilization of the residual heat energy of the radiant tube combustion exhaust gas. The difference between the present invention and the original gas jet heating technology is mainly that the heat exchanger is built in the preheating section, and after heat exchange with the furnace protection gas in the preheating section, the jet will heat the strip steel. The gas jet heating technology is used to heat the strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com