Measurement system and method of manufacturing shaft with hole

一种测量系统、测量控制的技术,应用在测量装置、制造工具、测量/指示设备等方向,能够解决无法测定空心轴壁厚、误差、多余等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

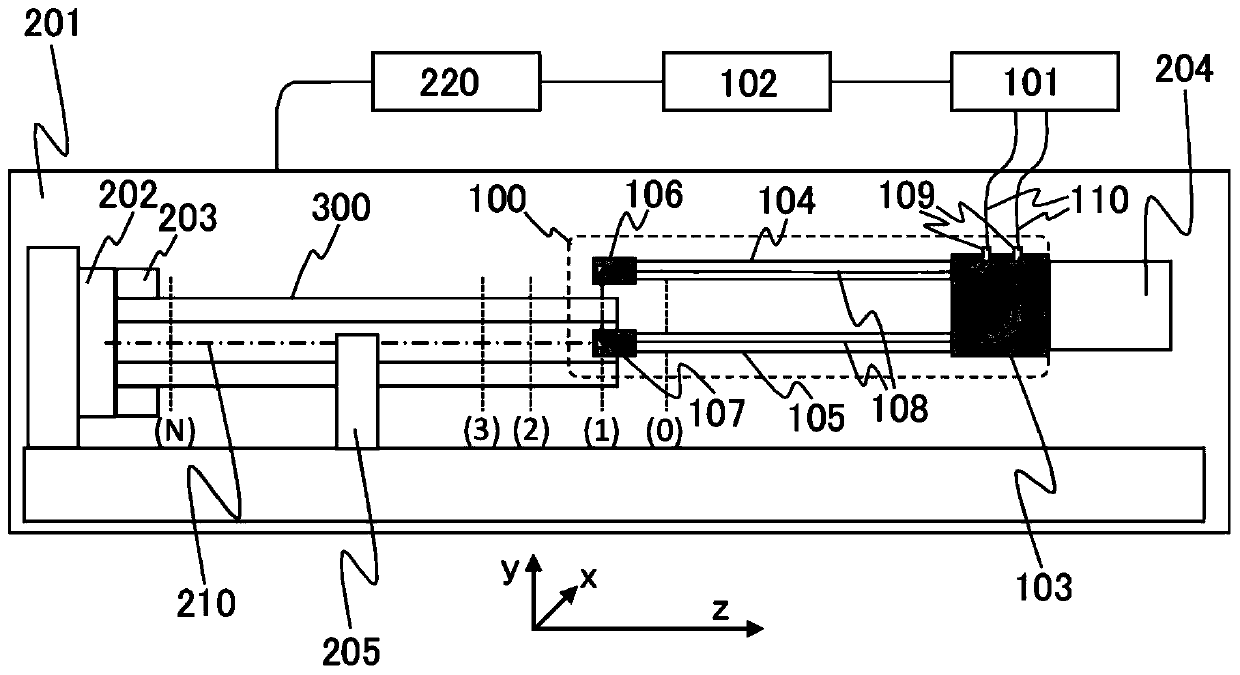

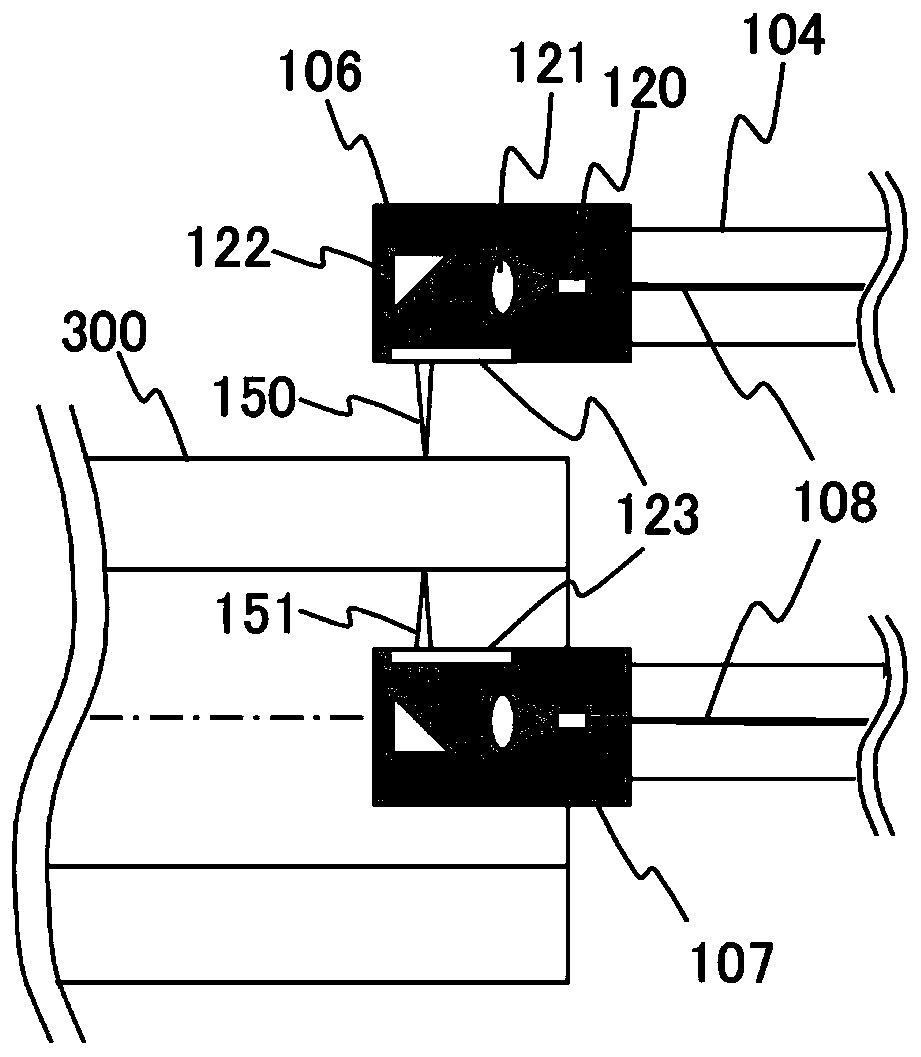

[0031] figure 1 The overall structure of the measurement system provided in the processing apparatus 201 in this invention is shown. The measurement system is a system composed of a measuring device 100 , a distance measuring device 101 , and a measurement control device 102 . In addition, the measuring device 100 is composed of measuring heads 106 and 107 , rods 104 and 105 , and a base 103 as will be described later. The distance measuring device 101 generates measurement light, and sends the measurement light to the connector 109 of the measurement device base 103 via two optical fibers 110 . The measurement device base 103 transmits measurement light to the measurement head 106 and the measurement head 107 via an optical fiber 108 . The measuring head 106 is a measuring head for the outer circumference, and the measuring head 107 is a measuring head for the inner circumference. figure 1 The outer peripheral part and the inner peripheral part of the cross-section of the ...

Embodiment 2

[0072] Next, use Figure 9 , Figure 10 , to illustrate an example of more accurately measuring the values of the inner diameter and the outer diameter. Measurement is performed by moving the measuring device 100 in the -Z direction using the tool shaft / tailstock 204 of the processing device 201 , but a slight pitch or yaw (α) occurs as the tool shaft / tailstock 204 moves in the -Z direction. Even if α is an inclination that does not usually cause a problem, since the rods 104, 105 holding the measuring heads 106, 107 are long, as in Figure 9 As shown exaggeratedly in the figure, the Y-direction positions of the measuring heads 106 and 107 change somewhat. When L is the length of the rods 104 and 105, the amount of change corresponds to Lα. When L is 1000 mm or more, even if α is 100 microrads, for example, Lα becomes a displacement of 0.1 mm. This means that in Figure 4 Defined in , the value of the offset Δ between the rotation axis 210 and the surface of the protect...

Embodiment 3

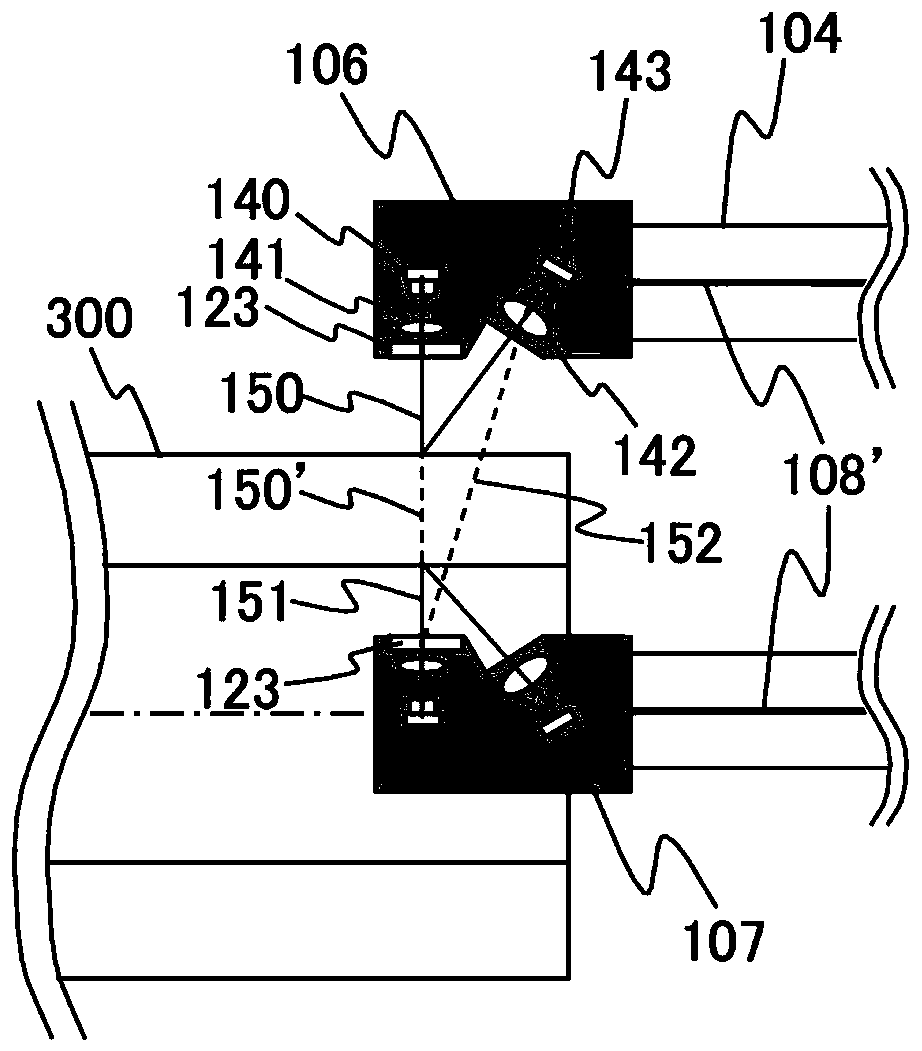

[0078] In Example 2, the deviation of the measured values of the inner diameter and the outer diameter was corrected using the measurement results of other measuring instruments such as a touch probe and a micrometer, but Figure 11 An example is shown in which the deviation of the measured values of the inner diameter and the outer diameter is corrected using the measuring device 100 itself.

[0079] Two or more groups of optical fiber 108, fiber end 120, lens 121, reflector 122, and protective window 123 of inner circumference measuring head 107 can be set, and additional measurement light 151' can be emitted radially. Figure 11 In (C)-1 is the structure of the case of 2 groups, Figure 11 In (C)-2 is the structure of the situation of 4 groups, Figure 11 (C)-3 in (C)-3 is the structure of the case of 3 groups.

[0080] Figure 11(A) in is the overall structure diagram of the situation of 2 groups, in this case, 1 is used for the outer circumference, and 2 is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com