Multiple piece reflective angle transformer

A technology of reflection ring and reflector, applied in the direction of reflector, semiconductor devices of light-emitting elements, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

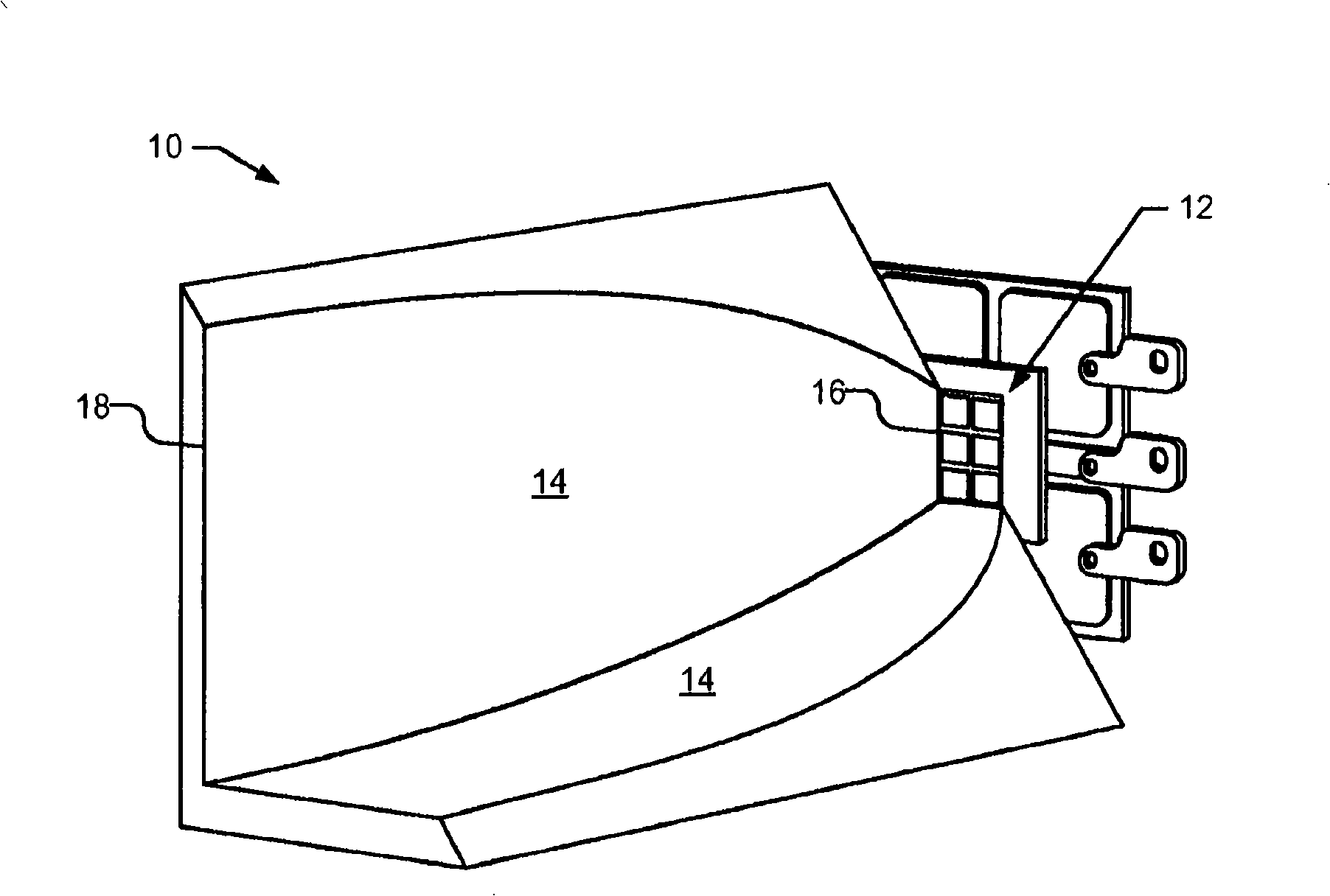

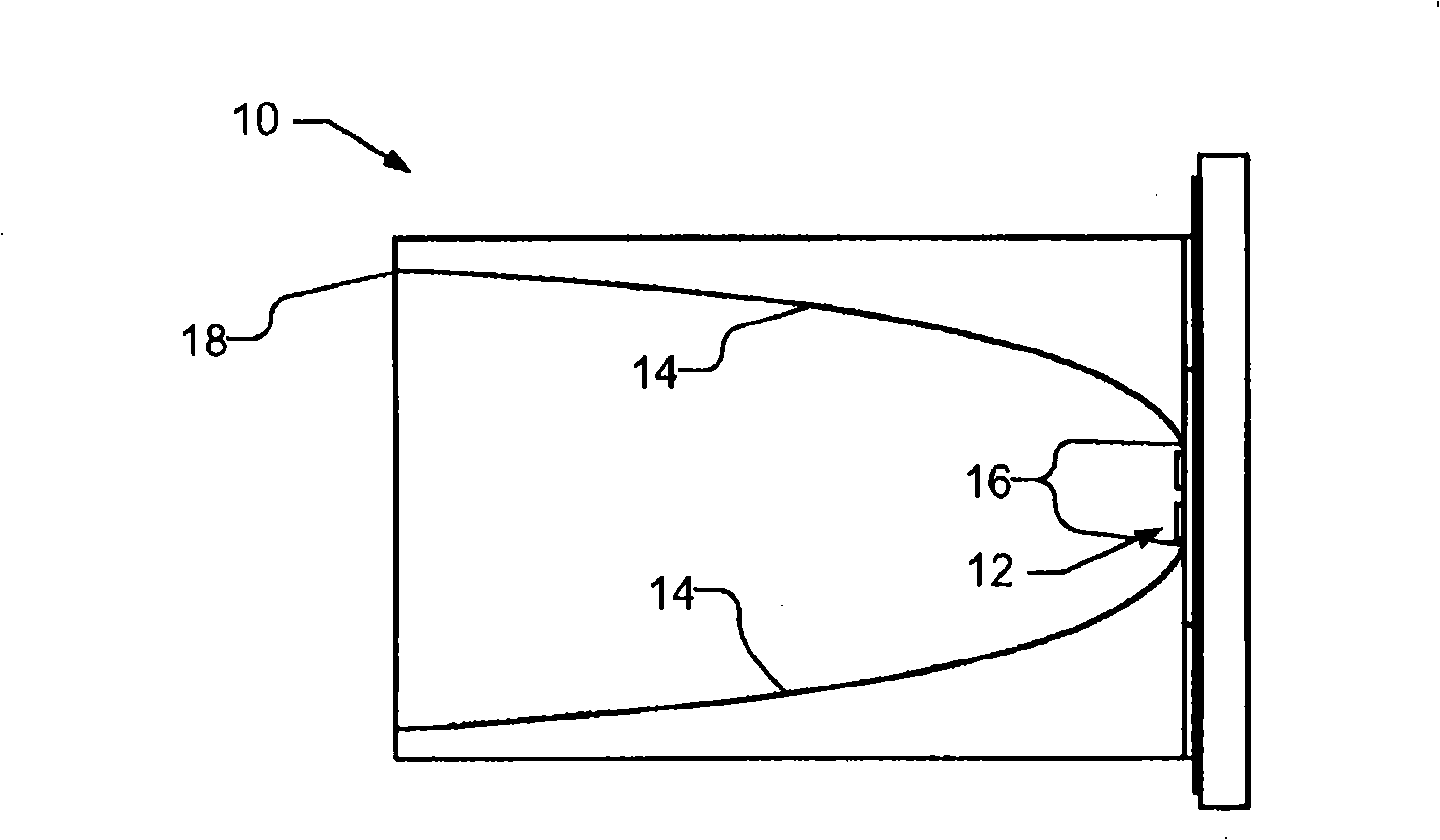

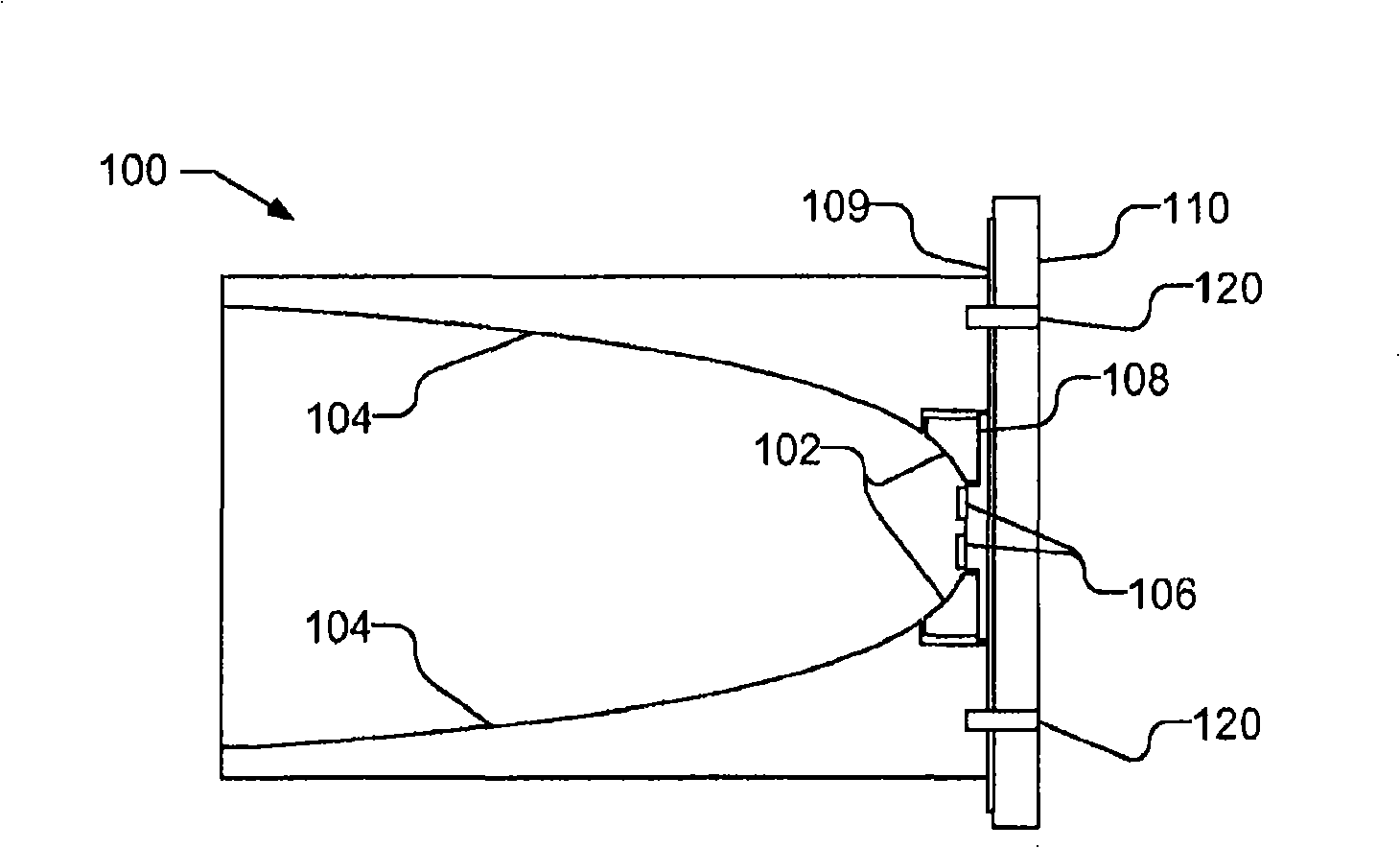

[0010] figure 1 with figure 2 A cross-sectional perspective view and a cross-sectional view of the light concentrating device 10 used with the light emitting diode array 12 are shown. The light concentrating device 10 may be, for example, a reflection angle converter, which is used to collimate the light emitted from the array 12. As can be seen, the light concentrating device 10 includes a continuous reflective side wall 14. Therefore, from the edge 16 of the reflective sidewall closest to the array 12 to the end 18 of the reflective sidewall, the concentrating device 10 is one piece.

[0011] In order to improve efficiency, it is desirable that the edge 16 of the reflective sidewall 14 is as close to the array 12 as possible. Moreover, in order to reflect any light emitted through the sidewall of the LED, the edge 16 should be a knife edge. Therefore, the light concentrating device 10 requires high-precision manufacturing and high-precision arrangement of the light concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com