Clutch gear manufacturing apparatus and clutch gear manufacturing method

A technology of gear manufacturing and manufacturing method, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, wheels, etc., can solve the problems of complicated manufacturing processes, deformation of taper holes, and increasing processes, so as to reduce the number of processes and restrain the increase of the number of processes. , the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the best mode for carrying out the present invention will be described using examples.

[0036] First, the clutch gears used in the product multi-cone synchronizer will be described.

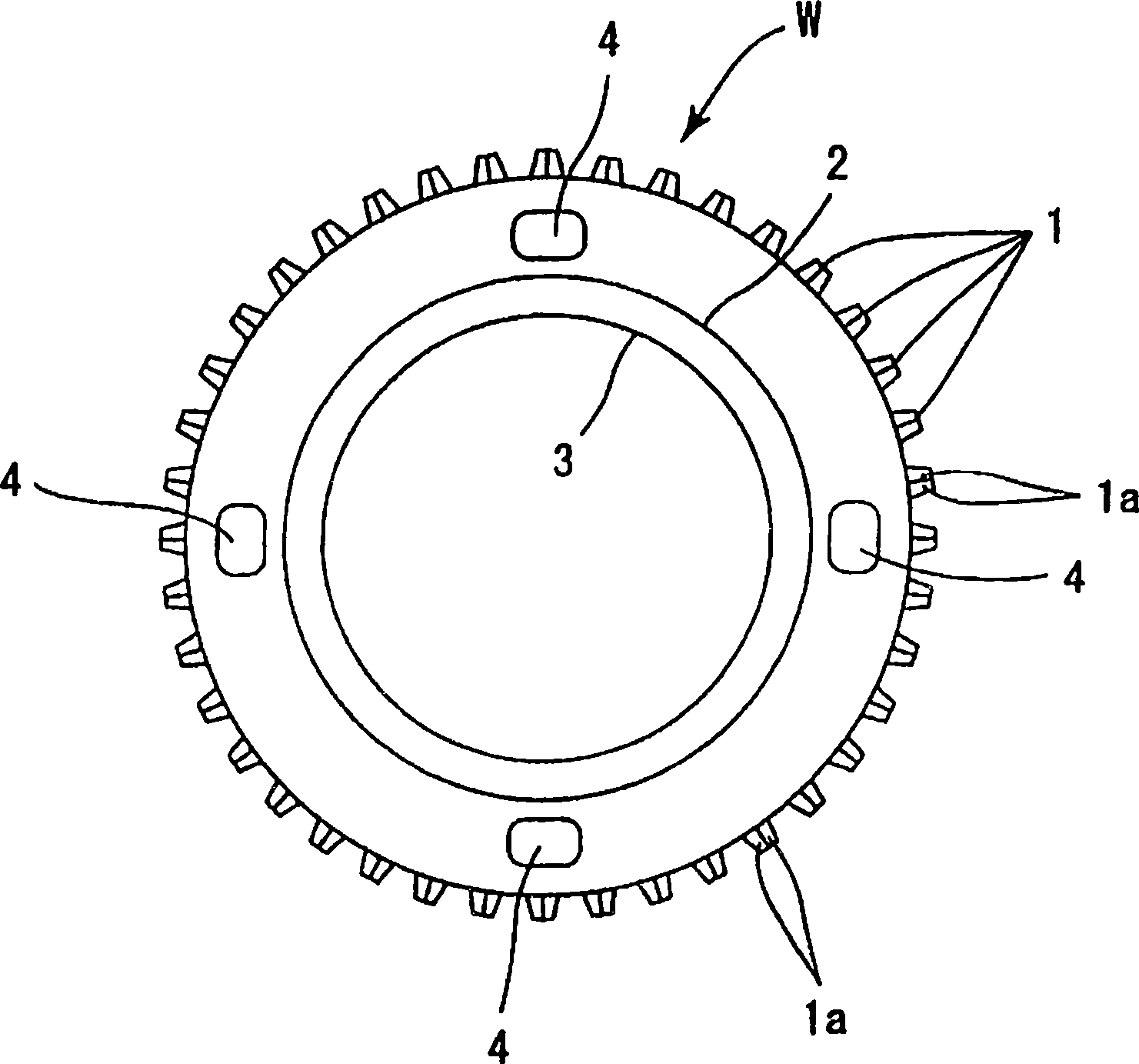

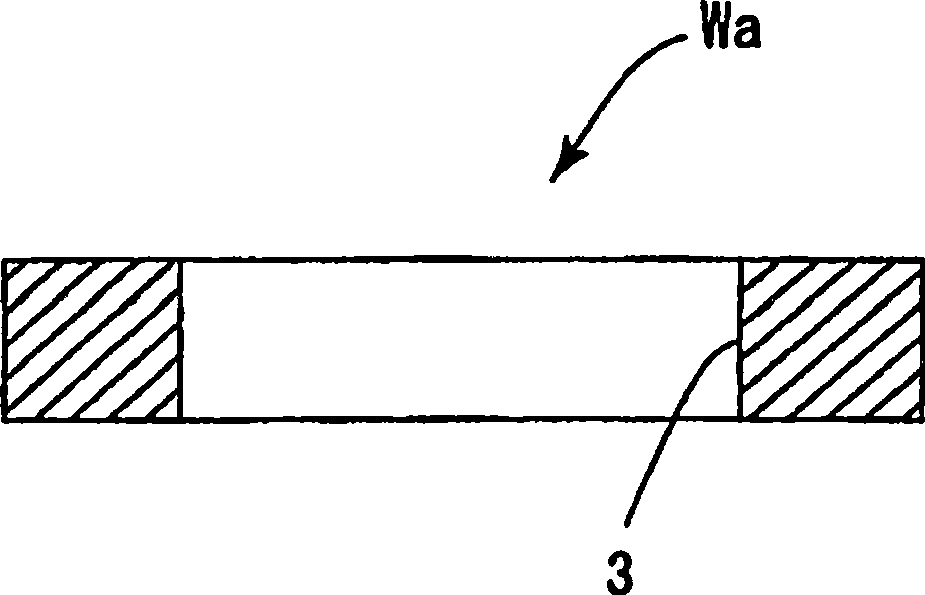

[0037] figure 1 It is a front view of a clutch gear manufactured by a clutch gear tooth manufacturing device and a reverse taper forming device.

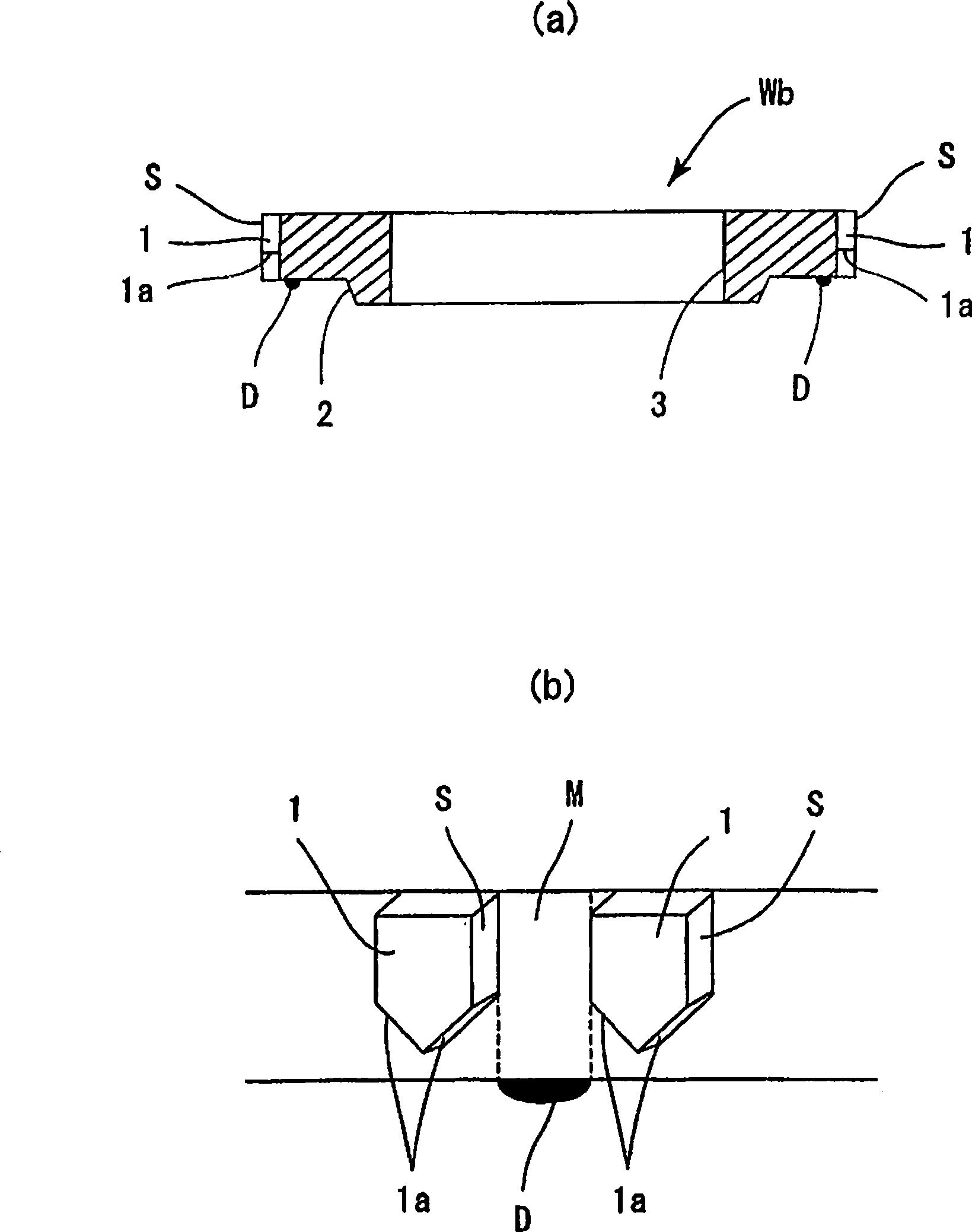

[0038] The clutch gear W has a plurality of spline teeth 1 formed at intervals on its outer periphery, and a herringbone-shaped chamfer 1a is formed at the end of each spline tooth 1 .

[0039] Moreover, on the side of the clutch gear W, a tapered portion 2 is formed on the inner peripheral surface 3 side, and four tapered holes are formed at equal intervals between the tapered portion 2 and the spline teeth 1 on the side surface of the clutch gear W. 4.

[0040]The taper hole 4 is formed to be engageable with a claw portion of the center cone so that the center cone disposed between the inner cone and the outer cone of the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com