Method for manufacturing surface unevenness

A technology of surface unevenness and production method, which is applied in the direction of photoengraving process, application and instrument of pattern surface, and can solve problems such as difficulty in forming unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

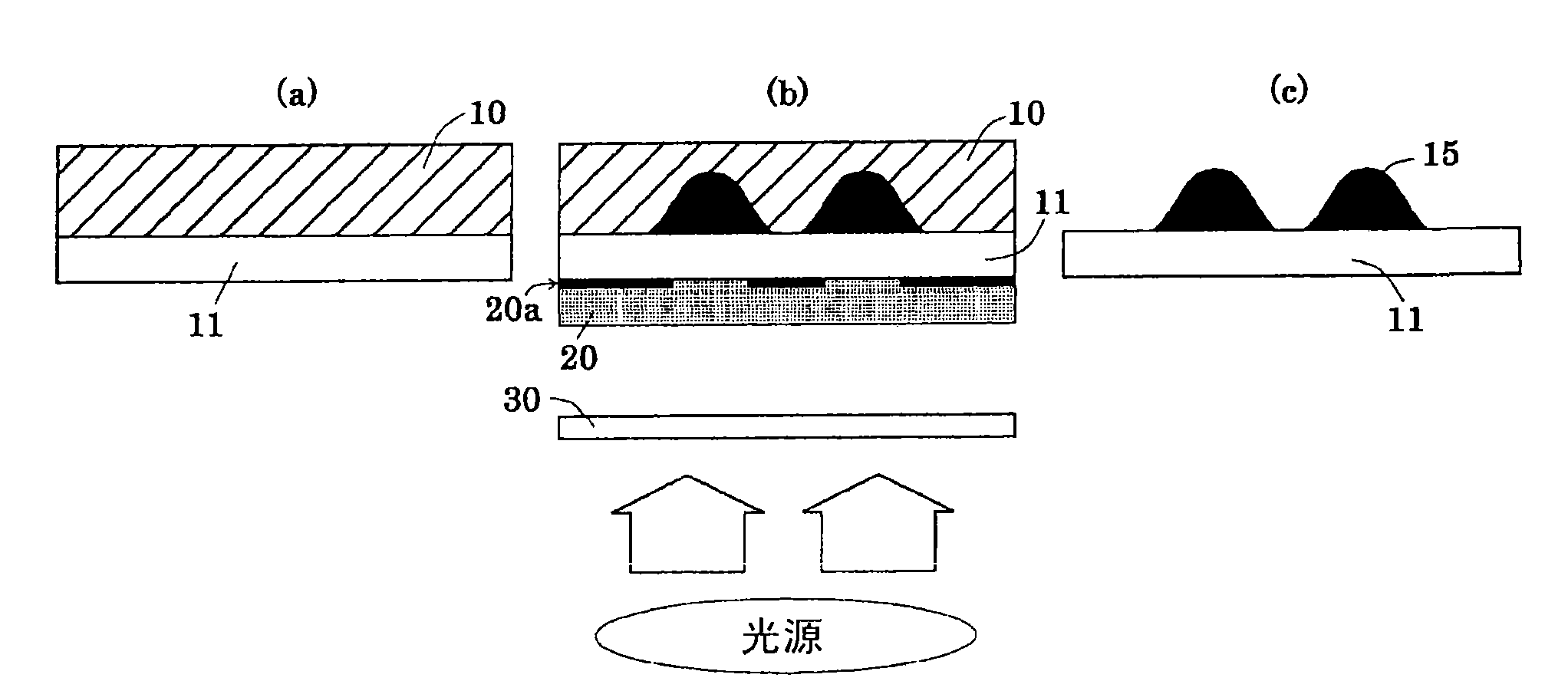

[0088] A resist (EKIRESIN PER-800RB-2203: Koyo Chemical Industry Co., Ltd.) was coated on a substrate 11 made of a polyester film (Coslnoshine A4300: Toyobo Co., Ltd., refractive index 1.64) with a thickness of 100 μm and dried to form a thickness 100 μm photosensitive film 10 .

[0089] Next, a film (Light-Up TL2: KIMOTO Co., Ltd.) having a light-diffusing member with an external haze of 30% was prepared.

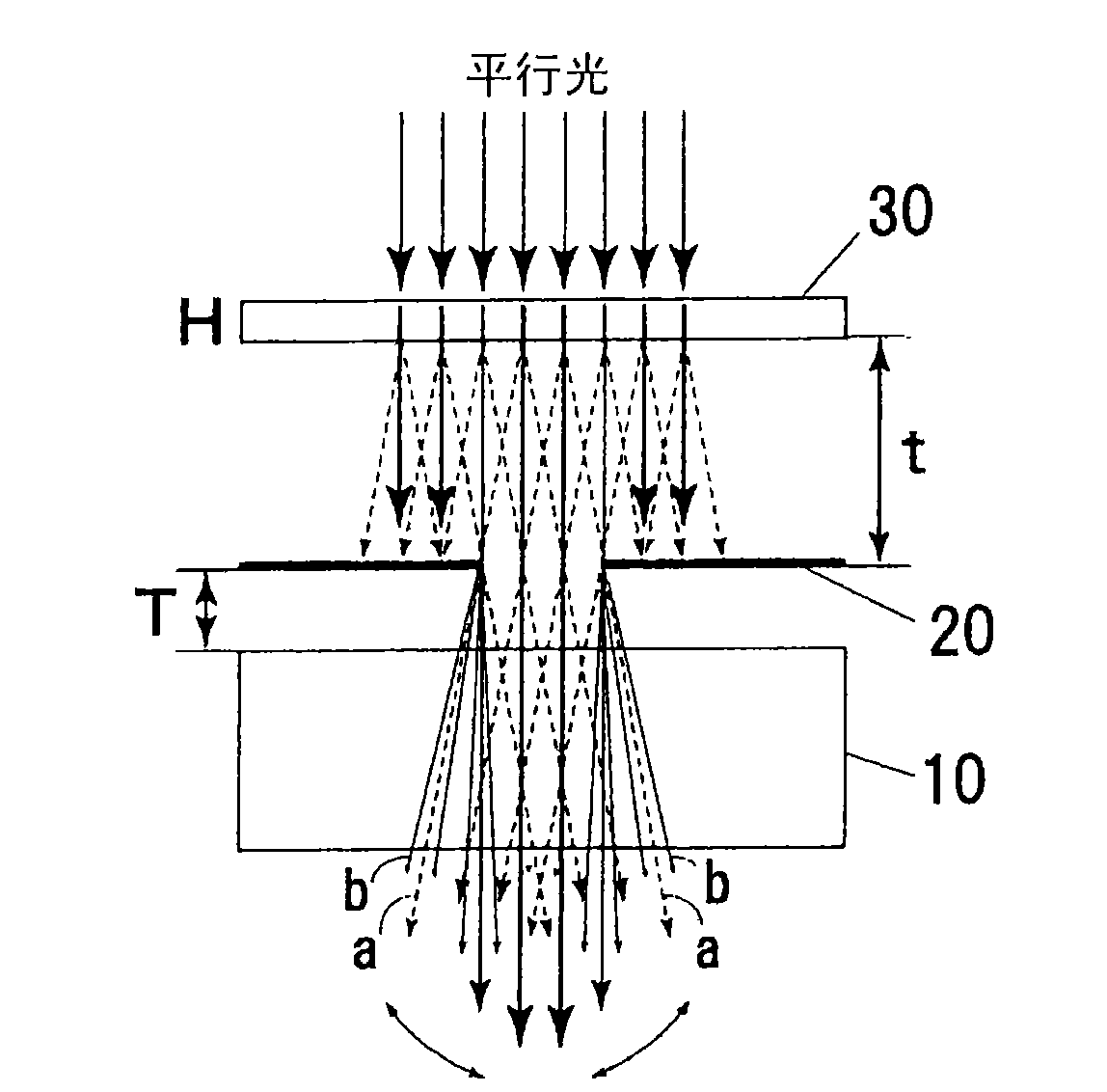

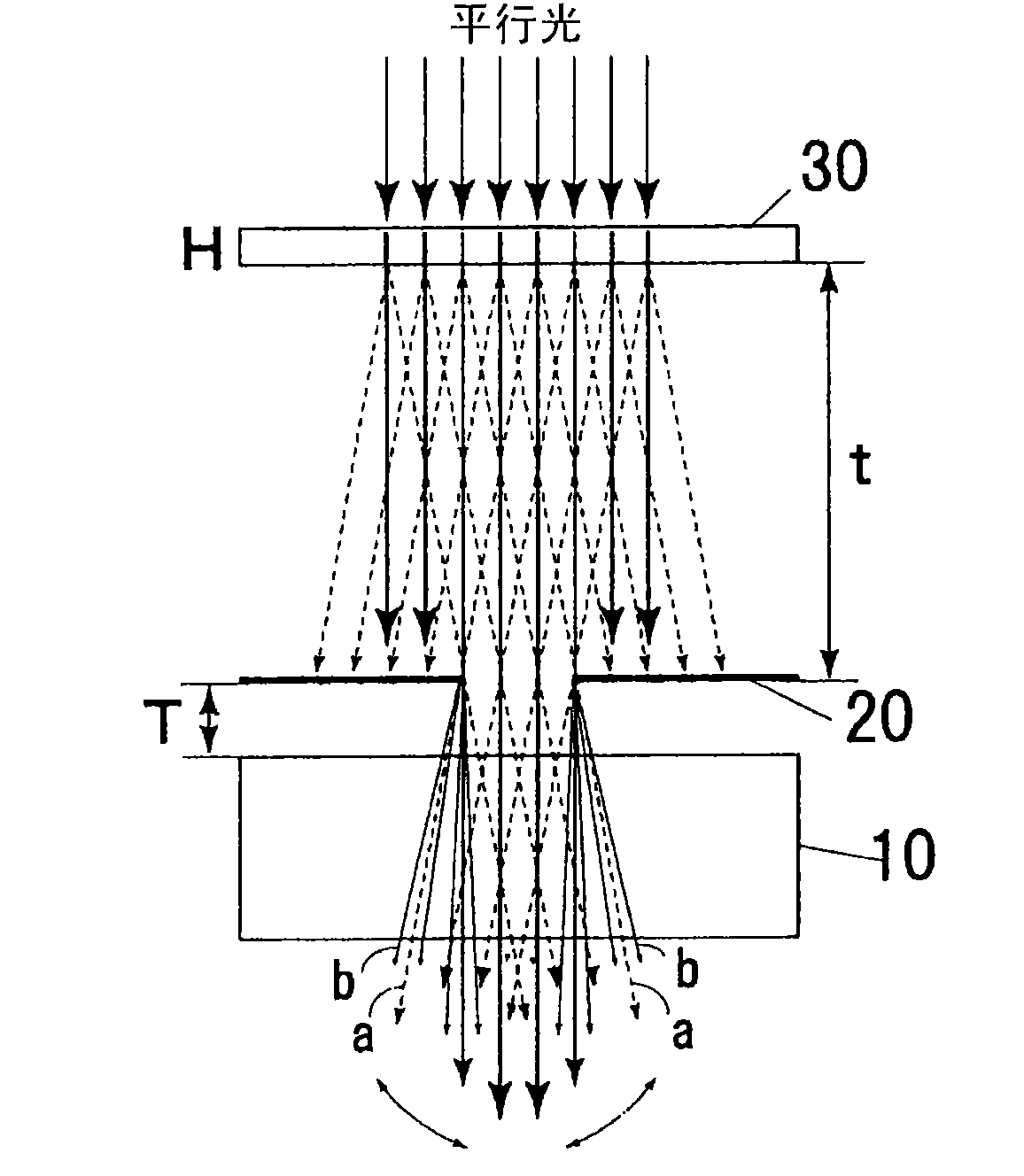

[0090] Then, the substrate 11 of the photosensitive film 10 is superimposed on the light-shielding surface 20a of the chromium mask 20 (hereinafter referred to as the Cr mask) having a plurality of circular openings formed thereon, and then the distance from the light-shielding surface of the Cr mask is 8.3 After setting the film with the light diffusing member 30 at mm ( Figure 10), the photosensitive film was exposed from the Cr mask side under the following conditions. Among them, two types of Cr masks having a mask diameter of 30 μm and 40 μm were prepared, and expo...

Embodiment 2~5

[0094] Except that the polyester film thickness of the substrate 11 to be the photosensitive film 10 and the external haze of the light-diffusing member 30 were changed as shown in Table 1, in the same manner as in Example 1, a film having unevenness formed on the surface of the substrate was obtained. sample. Among them, as a film having a light-diffusing member with an external haze of 65%, Light-Up SP6 (product name) from KIMOTO Co., Ltd. was used, and as a film having a light-diffusing member with an external haze of 86% , Light-Up DP8 (product name) of KIMOTO Co., Ltd. was used.

Embodiment 6

[0096] Except having used the film of the following Example 6 as a film which has a light-diffusion member, it carried out similarly to Example 1, and obtained the sample which formed the uneven|corrugated on the base material surface.

[0097] On a base material comprising a polyester film (Cosmoshine A4300: Toyobo Co., Ltd.) with a thickness of 50 μm, a light-diffusing member coating solution of the following formulation is applied and dried so that the thickness after drying is 5 μm, and then the light-diffusing The same polyester film was laminated on the member to form a light-diffusing member 30 having an internal haze of 5%, and a film having a light-diffusing member (film of Example 6) was obtained.

[0098]

[0099] ·Acrylic resin 100 parts

[0100] (ACRYDIC A-807: Dainippon Ink Chemical Industry Co., Ltd.)

[0101] (solid content 50%)

[0102] ·Spherical particles (silicon dioxide) 3 parts

[0103] (TOSPEARL 105: GE Toshiba Silicone Corporation)

[0104] (refra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com