Manufacturing device for tire ply material

A tire cord, layer material technology, applied in tires, applications, household appliances, etc., can solve problems such as difficulty in effectively using transfer devices, poor versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

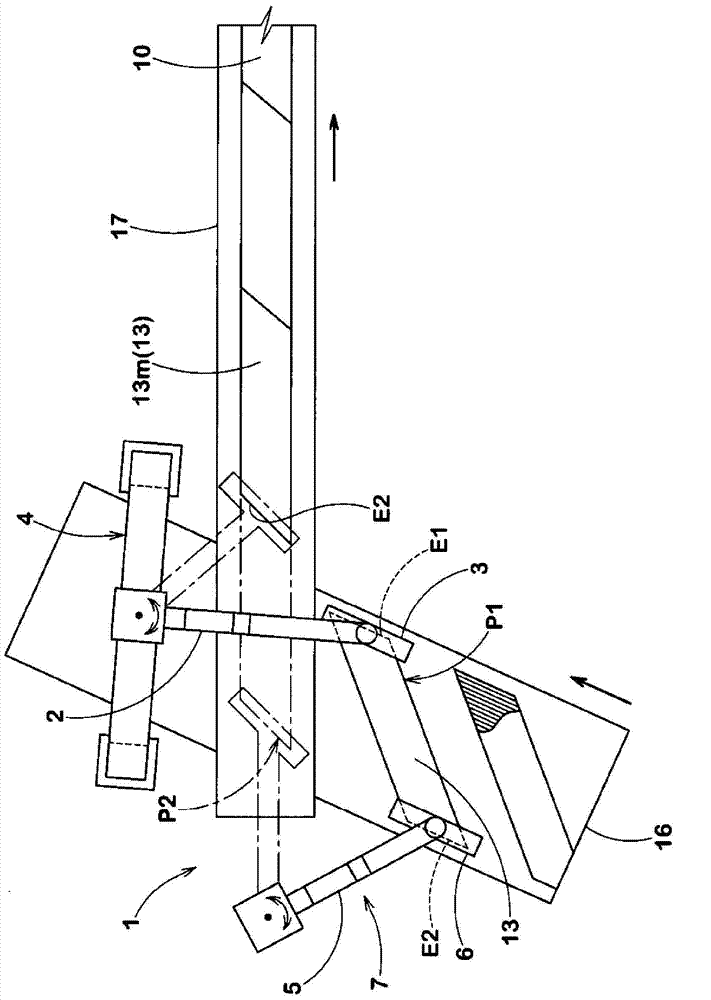

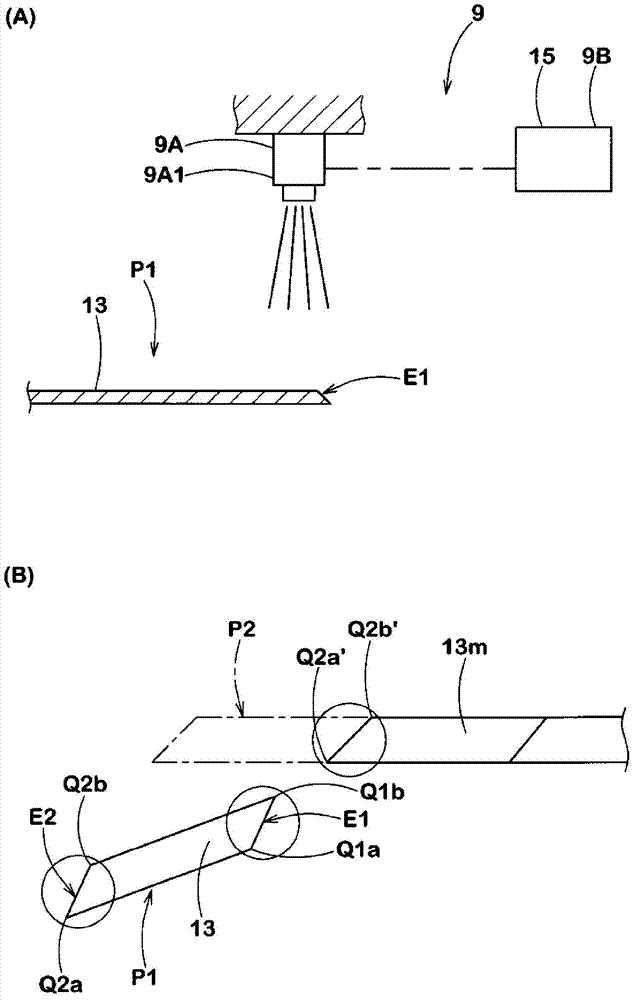

[0037] Embodiments of the present invention will be described more specifically with reference to the accompanying drawings. Such as figure 1As shown in , the manufacturing equipment for tire carcass material of the present embodiment (hereinafter sometimes simply referred to as "carcass material manufacturing equipment") 1 makes the cutting member 13-the cutting member 13 has been moved by such as a belt conveyor The conveying device 16 is placed at the loading position P1 - moves to the joining position P2 on the conveyor 17 and then joins the cut piece 13 to another cut piece 13m previously placed at the joining position P2 to form a longer tire Ply material 10.

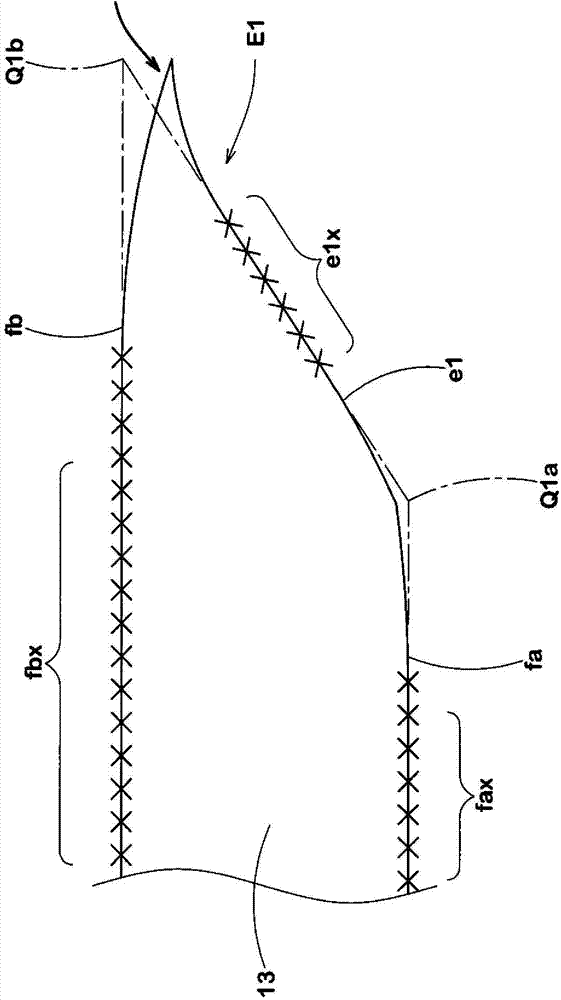

[0038] Such as Figure 11 As shown in , the cutting member 13 has a parallelogram shape obtained by sequentially cutting longer strip-shaped bodies 12 at an angle θ with respect to the cord longitudinal direction of the tire cord 11, in which, The aligned bodies of a plurality of parallel tire cords 11 are cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com