Wheel center distance variable axle of trailer

A technology for axles and trailers, applied to axles, wheels, vehicle parts, etc., to save space, prevent misalignment, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiment of the invention

[0042] A first embodiment of the present invention will be described below with reference to the drawings.

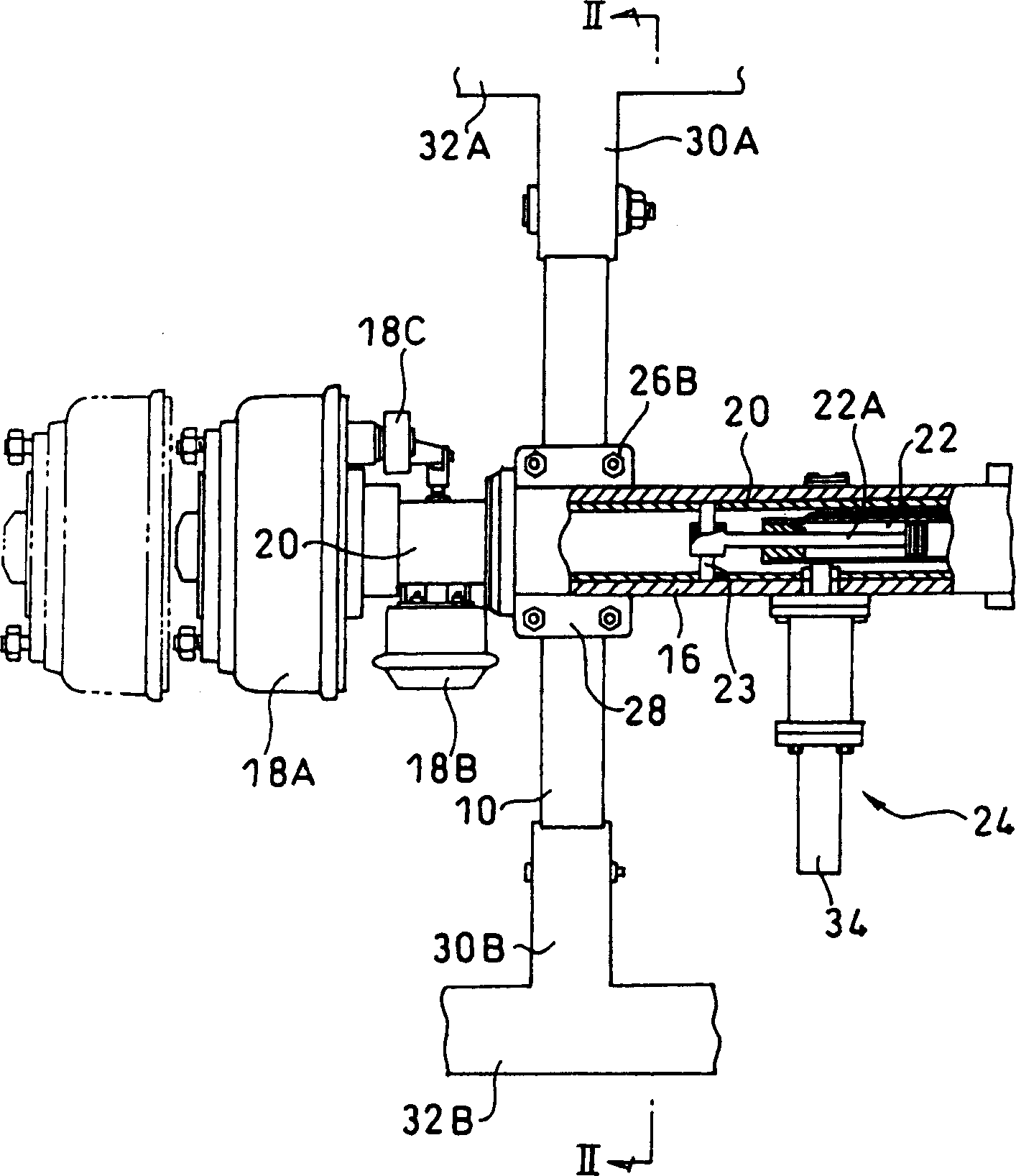

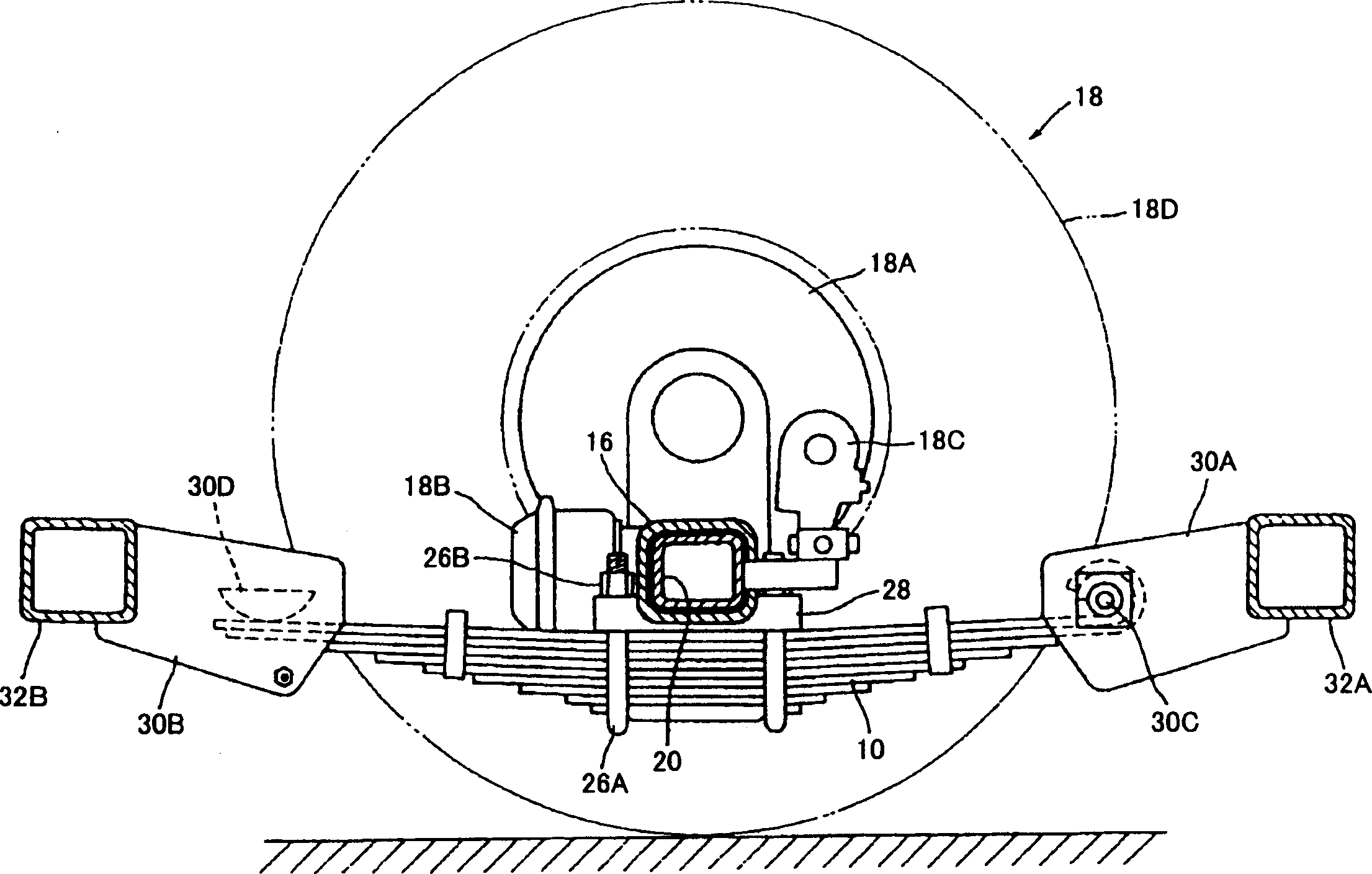

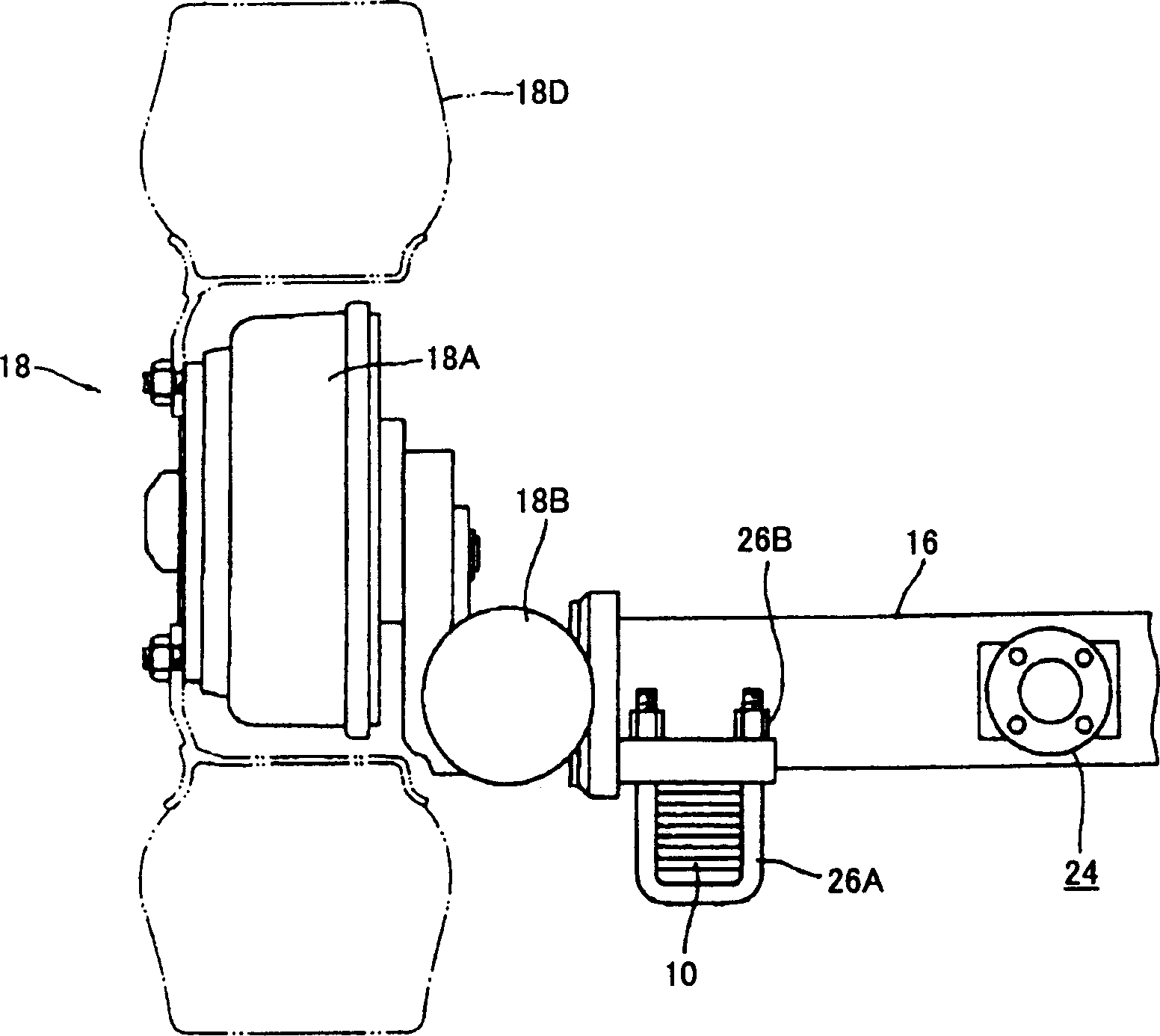

[0043] The example is Figure 1 to Figure 5 As shown, the configuration of the variable wheelbase axle of the trailer 12 includes a cylindrical outer axle 16 with a square section supported on the vehicle body 14 of the trailer 12 through a leaf spring 10, which is telescopic and cylindrical and can slide freely in the axial direction but cannot A rectangular cylindrical inner axle 20, which is rotatably supported in the outer axle 16 and at the end protruding from the outer axle 16, freely rotatably supports the wheel 18, is attached to the outer axle 16 to support the aforementioned outer axle 16. A hydraulic cylinder device 22 for axially driving the inner axle 20 , and a locking device 24 for fixing the position of the inner axle 20 relative to the outer axle 16 in the axial direction.

[0044] The leaf spring 10 is constrained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com