Method for producing scattering ray raster or collimator with ray absorption material

A collimator, ray technology, applied in the direction of using diaphragm/collimator, instrument for radiological diagnosis, radiation measurement, etc., can solve the problems of laborious and expensive manufacturing methods, and confusion of collimators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

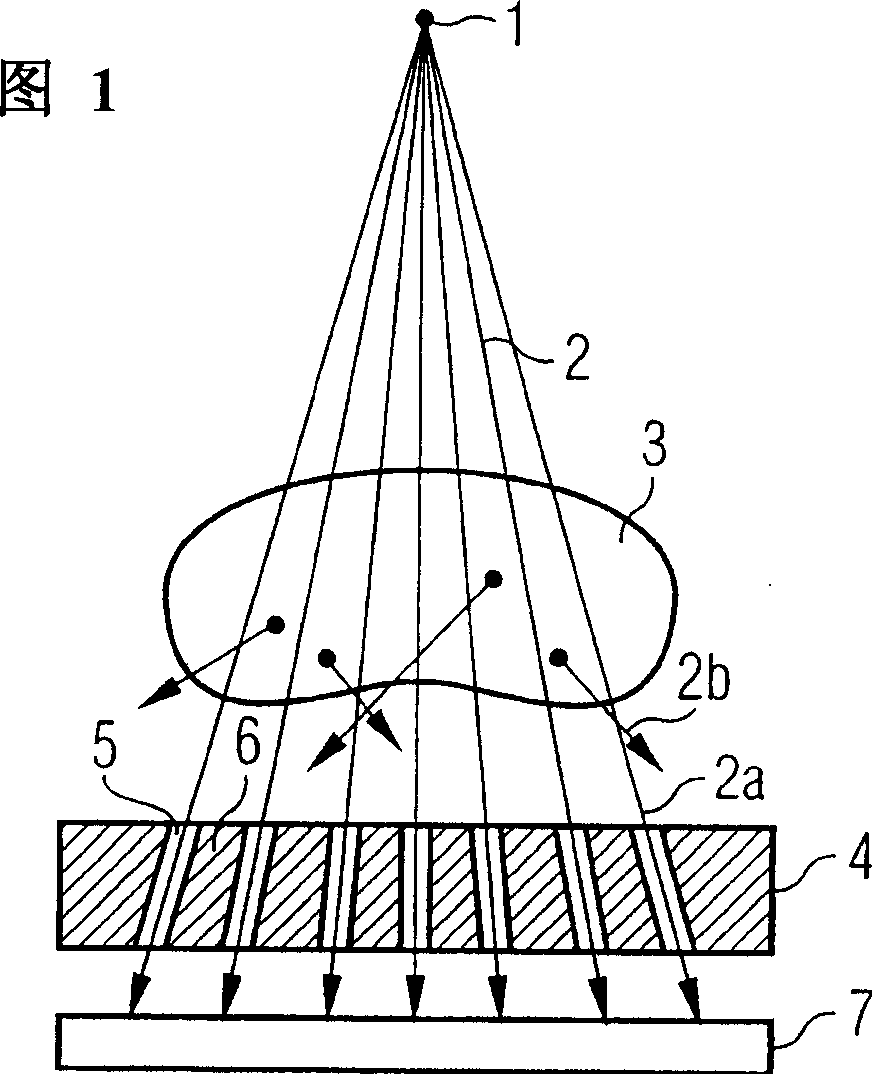

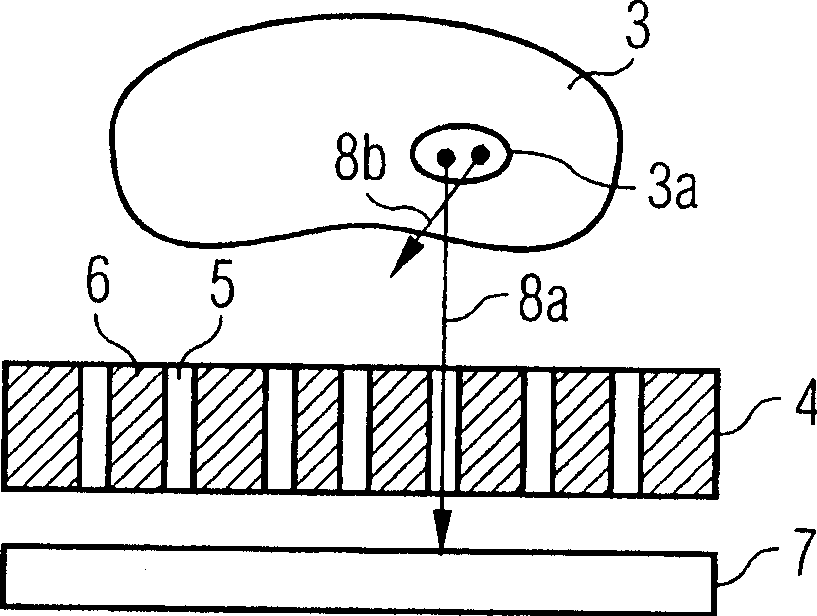

[0031] A typical situation during the radiographing of an object 3 is schematically depicted in FIG. 1 . The object 3 is located between an x-ray tube focus 1 which can be regarded as a point x-ray source and a detection surface 7 . The x-ray beam 2 emitted by the focal point 1 of the x-ray source spreads linearly in the direction of the x-ray detector 7 and passes through the object 3 there. The primary ray 2a emitted by the X-ray focal point 1 passing through the object 3 and impinging on the detection surface 7 produces a spatially resolvable attenuation value distribution on the detection surface 7 due to the object 3 . A part of the x-rays 2 emitted by the x-ray focus 1 is scattered in the object 3 . The resulting scattered radiation 2 b has a negative effect on the desired image information and significantly deteriorates the signal-to-noise ratio when impinging on the detector 7 . To improve the image quality, a scattered radiation grid is then arranged upstream of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com