Three-dimensional circuit module and method of manufacturing the same

A technology of three-dimensional circuit and manufacturing method, which is applied in the direction of printed circuit manufacturing, circuit, printed circuit, etc., can solve the problems of becoming complicated, lengthening the manufacturing process, increasing manufacturing cost, etc., and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

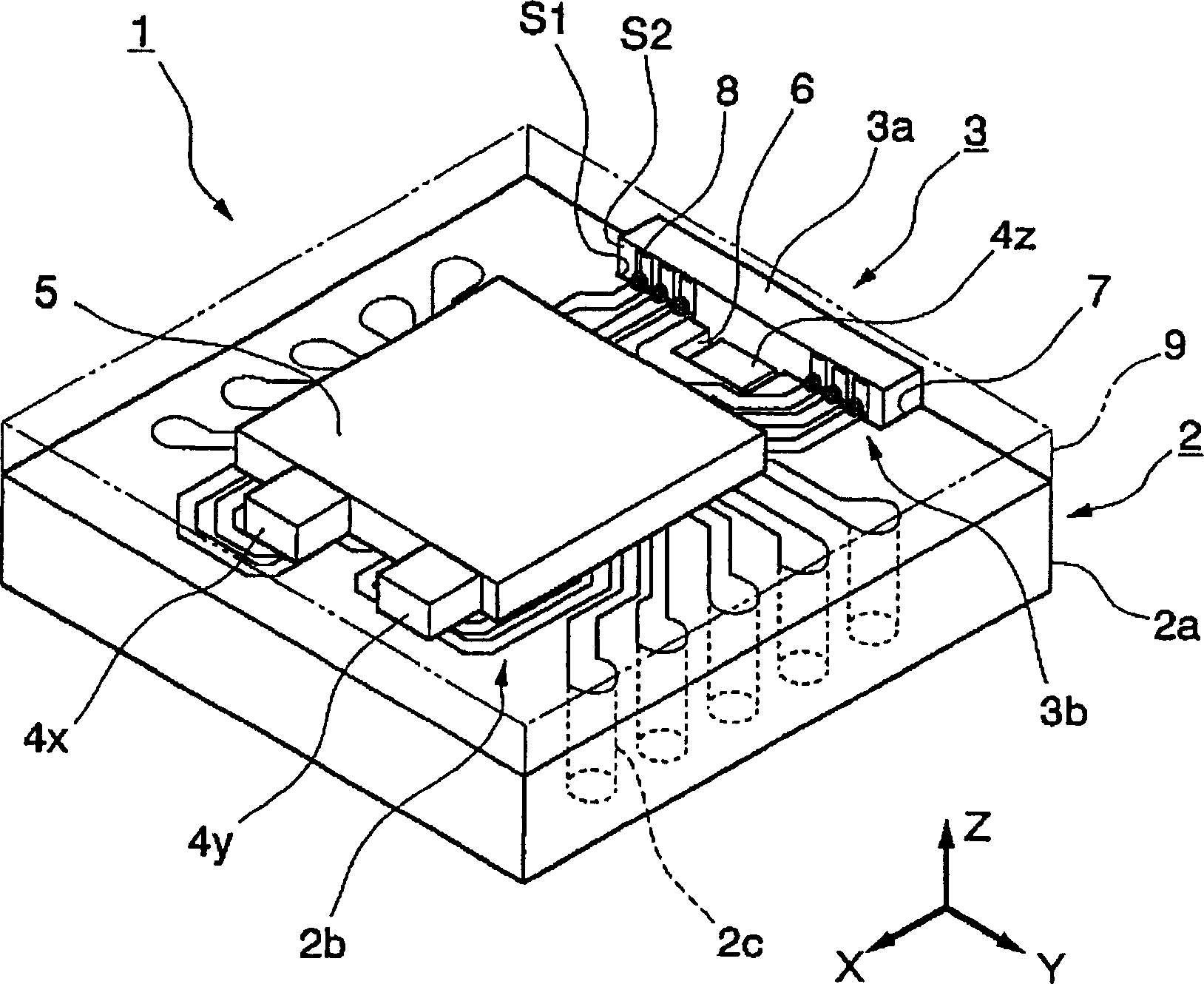

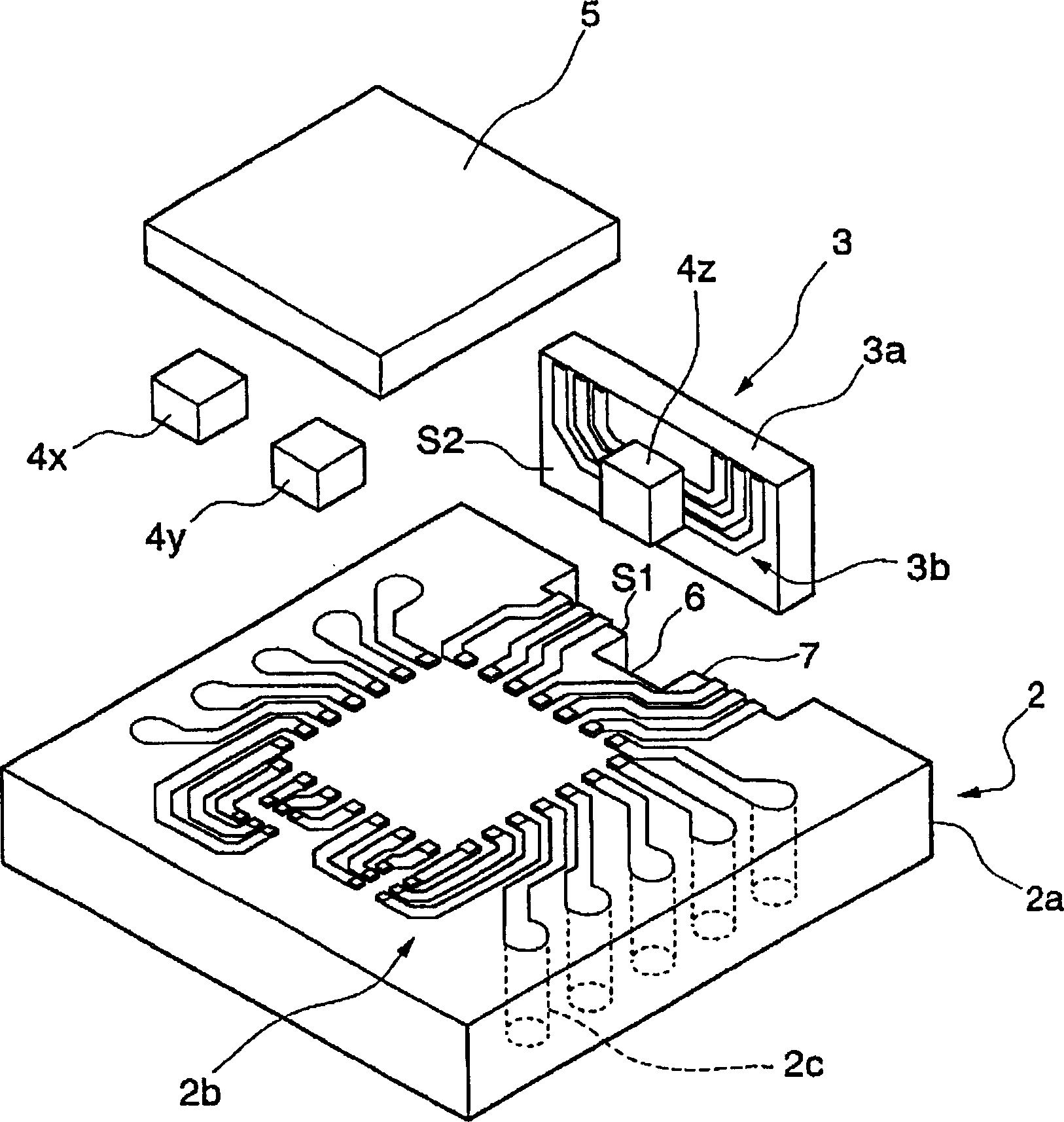

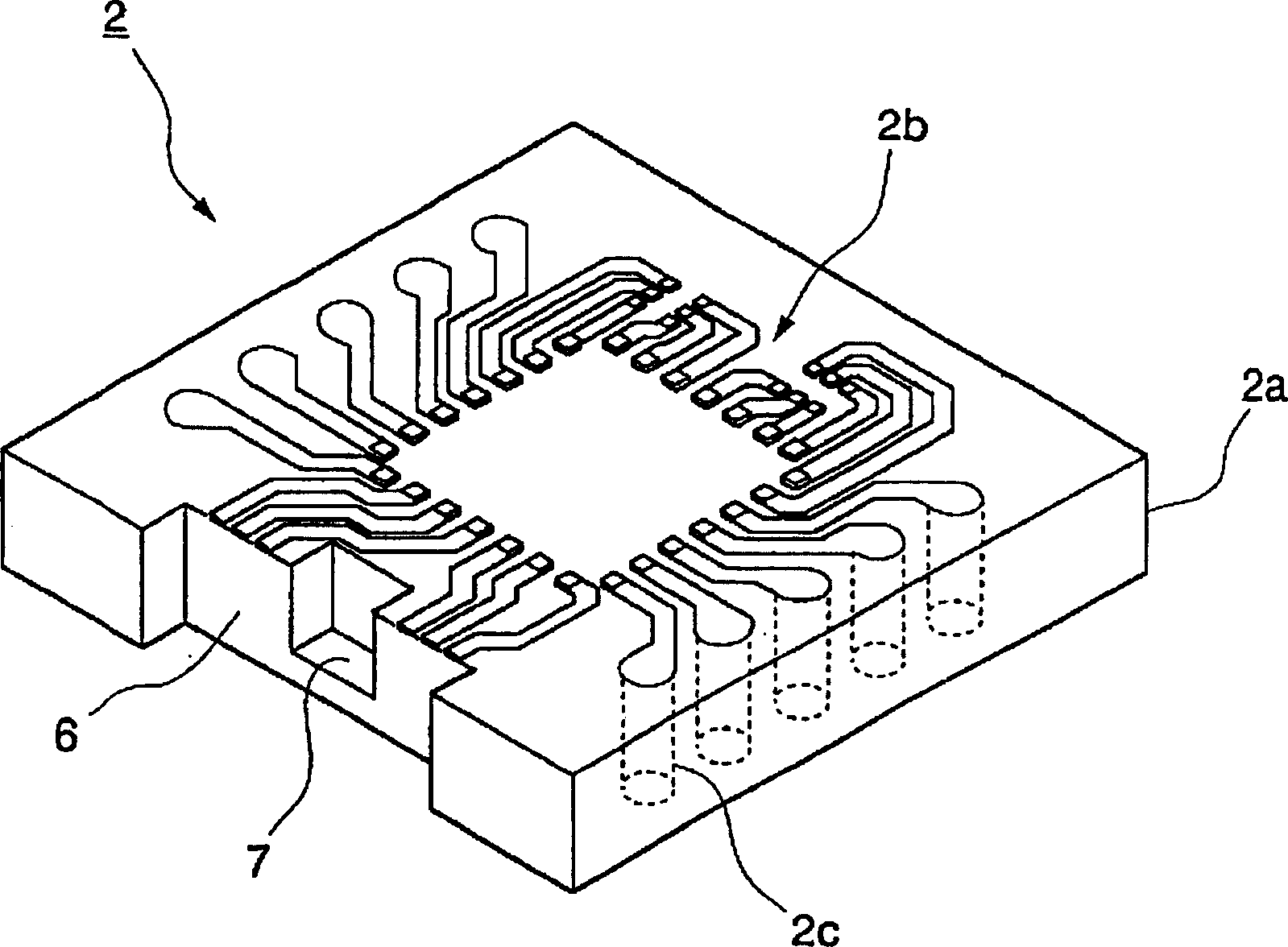

[0046] Hereinafter, the three-dimensional circuit module and its manufacturing method according to the present invention will be described in detail with reference to the drawings. In addition, the dimension, material, etc. of each part illustrated in the following description are an example, and this invention is not necessarily limited to the following dimension, material, etc. FIG.

[0047] Adopt the three-dimensional circuit module of the present invention, such as figure 1 The three-dimensional sensing module 1 is shown. The three-dimensional sensing module 1 forms a three-dimensional wiring circuit on the surfaces of the wiring substrates 2 and 3 with a three-dimensional structure, and through figure 1 Three magnetic sensors 4x, 4y, and 4z that have sensing functions in one axis are respectively arranged in the three axes of the X, Y, and Z axes shown in , so as to form a three-dimensional sensing module.

[0048] Specifically, as figure 1 and figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com