Cooling device for built-in-spindle type spindle motor of machine tool

A technology for spindle motors and cooling equipment, applied in electromechanical devices, electric components, cooling/ventilation devices, etc., can solve problems such as preventing high temperature, cooling efficiency degradation, and inability to cool rotors and stators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

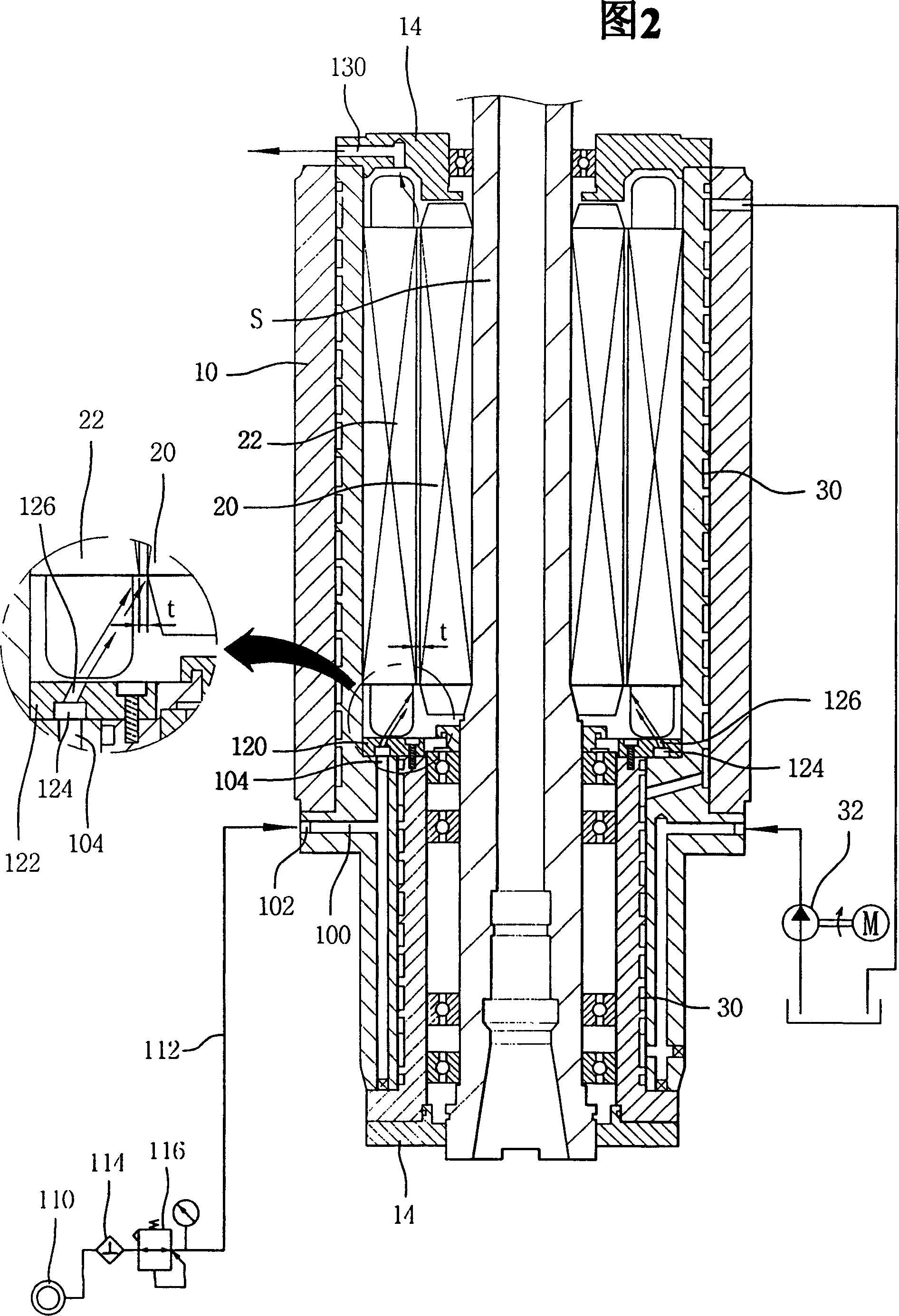

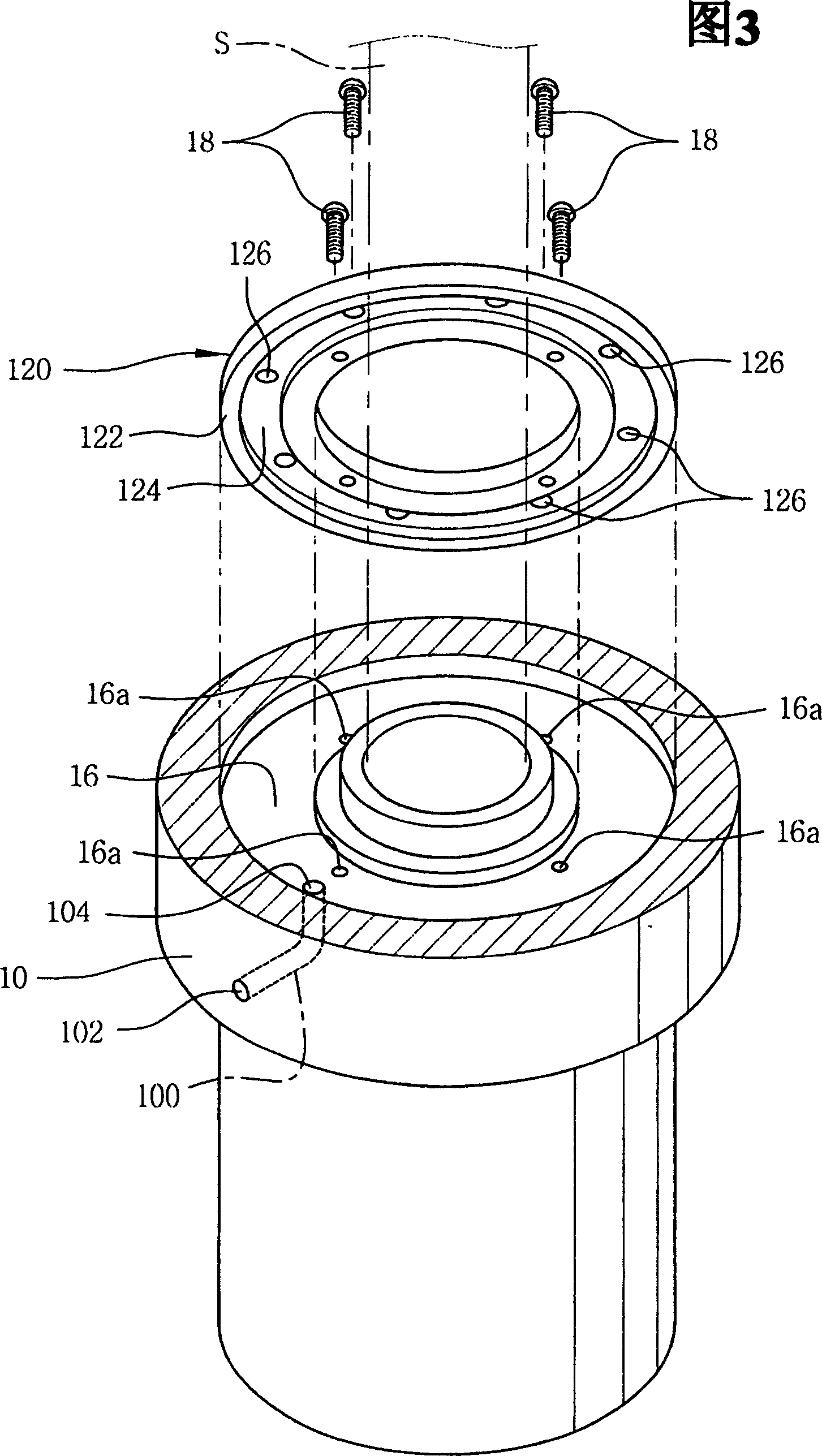

[0021] Next, preferred embodiments of the cooling apparatus for an internal shaft type spindle motor according to the present invention will be described in detail with reference to the accompanying drawings. Parts that are the same as those of the conventional equipment described above will use the same reference numerals as in the prior art.

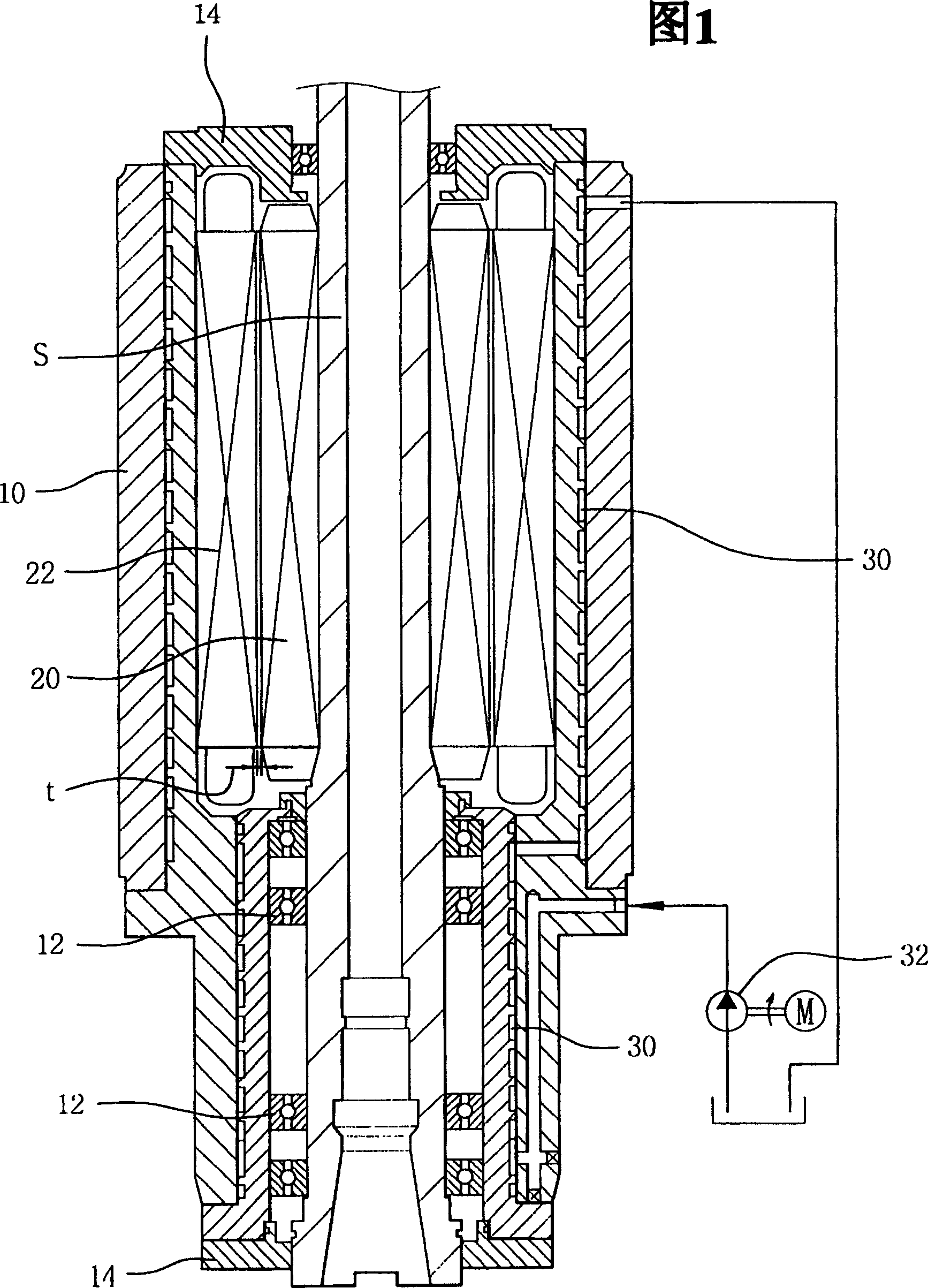

[0022] Before explaining the spindle motor cooling device of the present invention, the structure of the spindle motor will be briefly described with reference to FIG. 2 . As shown, the spindle motor includes a motor housing 10 . The motor housing 10 is provided to enclose the main shaft S. As shown in FIG. Opposite ends of the motor housing 10 are sealed with covers 14 .

[0023] In addition, the spindle motor includes a rotor 20 fixed around the rotor 20 and a stator 22 disposed around the rotor 20 with a gap formed between the rotor and the stator. The stator 22 is fixed to the inner circumferential surface of the motor housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com