Displacement pump with variable volume flow

a variable-volume flow, displacement pump technology, applied in the direction of rotary or oscillating piston engines, engine lubrication, rotary piston engines, etc., can solve the problems of inability to arbitrarily reduce the diameter of the gear ring running set, the outer diameter of the variable pump is too large, and the design space of the variable pump is reduced. , to achieve the effect of reducing hydrostatic losses, reducing hydrostatic losses, and compactness of the variable-volume pump according to

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

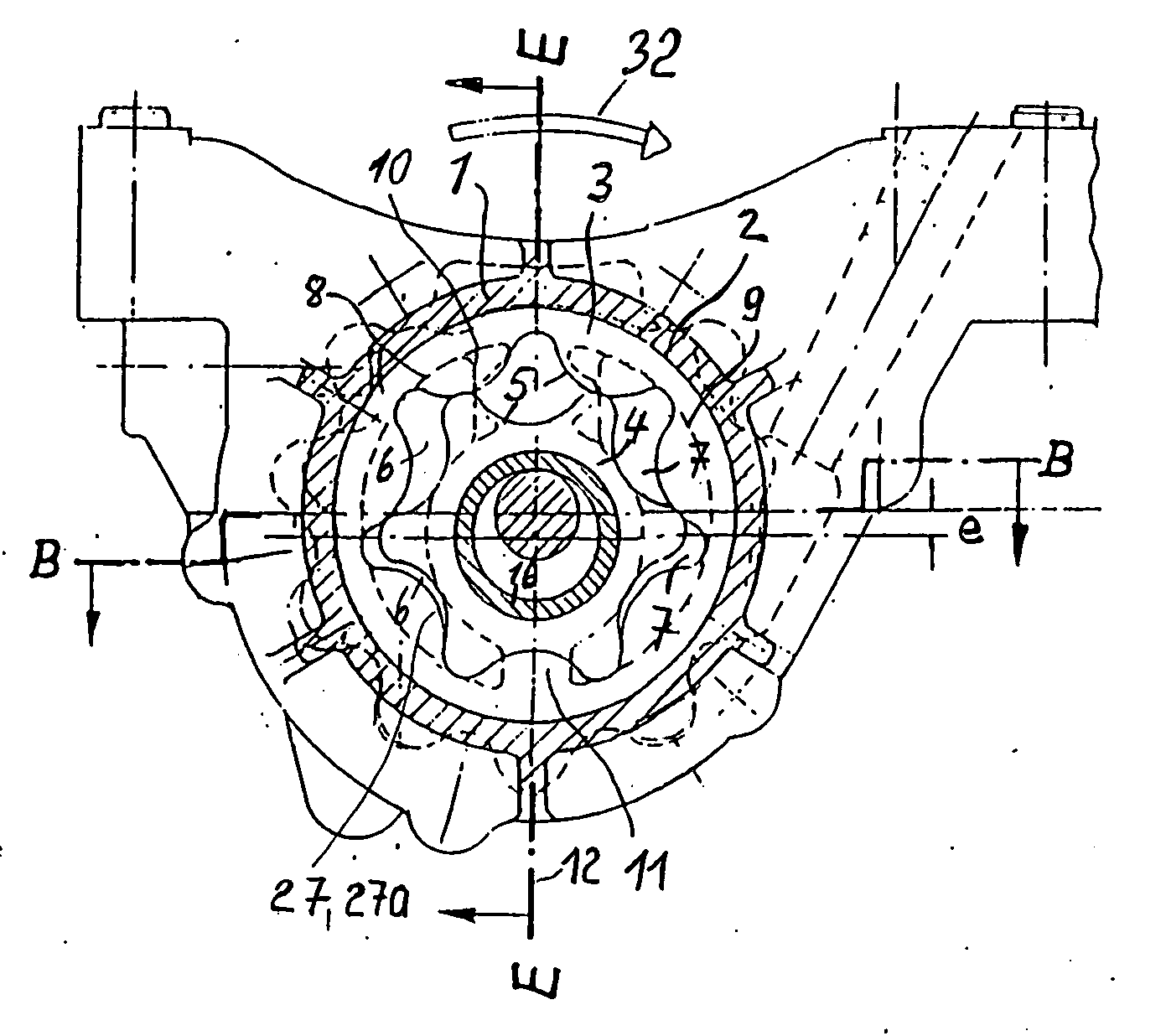

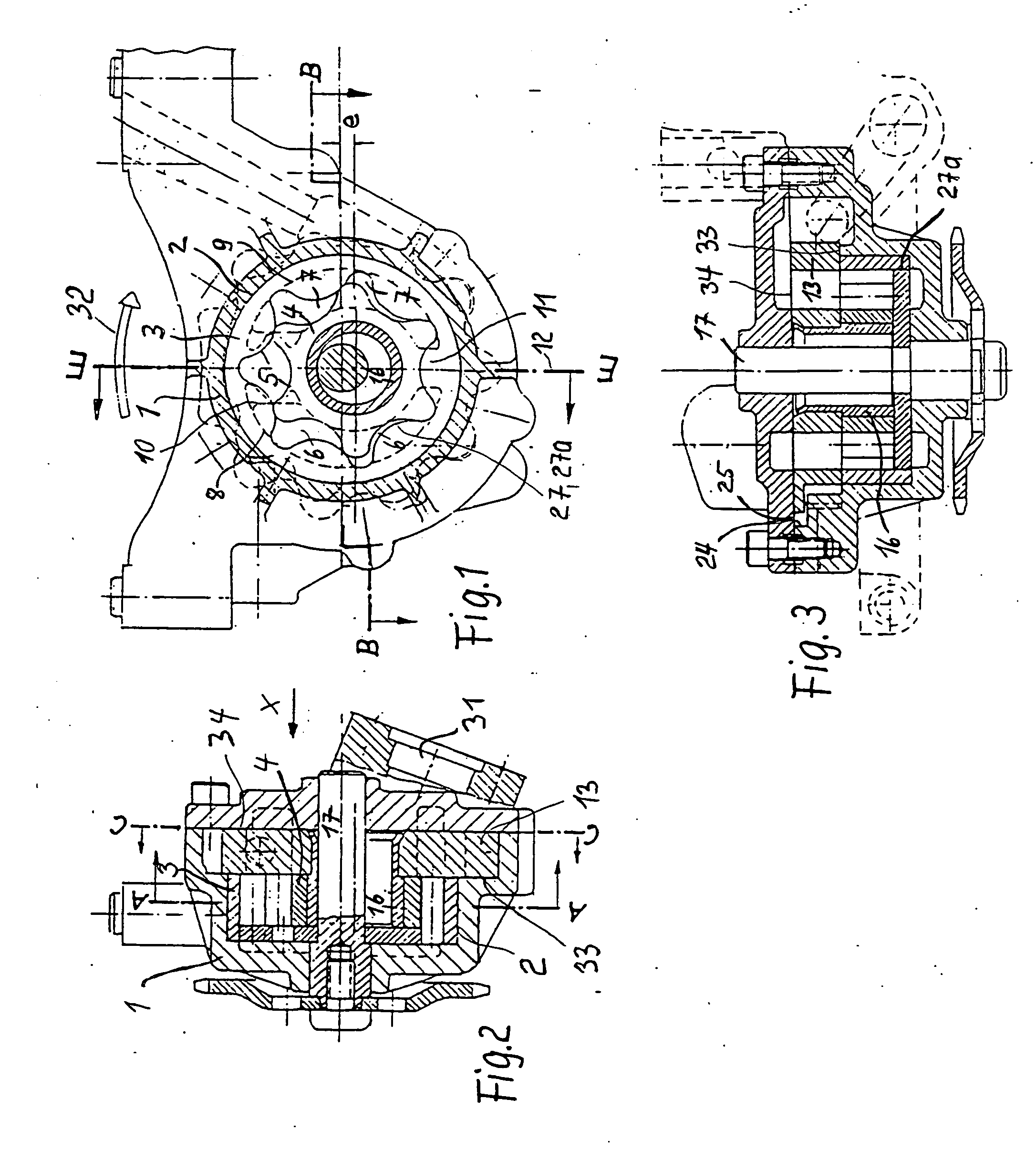

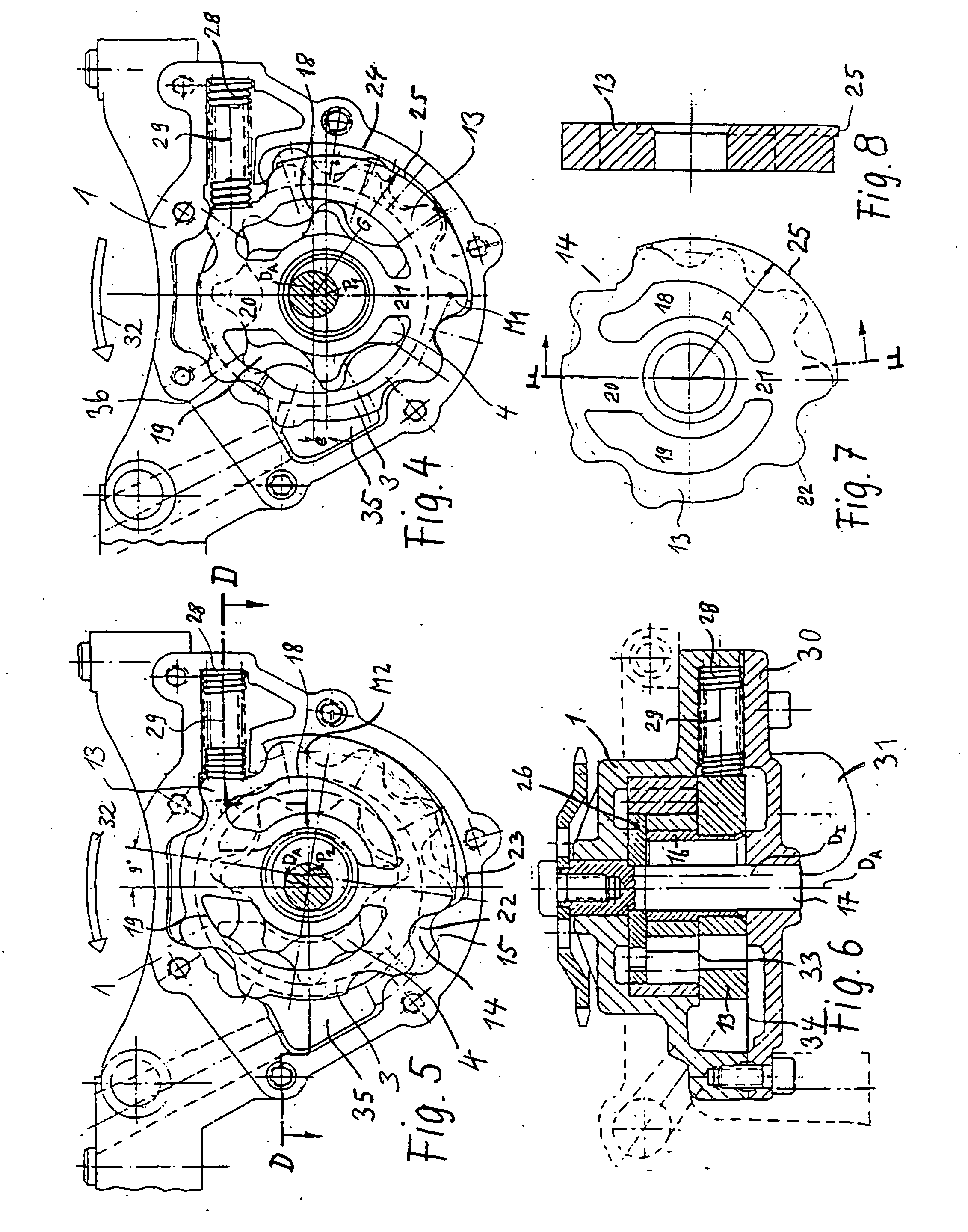

[0029] For explaining the function in the individual figures, the rotational direction of the running set shall be in the indicated direction of the arrow 32, such that the respective suction and pressure side in accordance with the expanding and compressing delivery cells of the teeth is clearly provided. In the cover 30, the suction support 31 is arranged on the suction side of the running set, on which side the variable spring 28 can also be seen. Thus, the spaces of the variable spring 28 and the rolling cylinders 24 and 25, and the sections of the toothing shown on the right of the image in FIGS. 4, 5, 6 and 7 between the variable plate 13 and the casing 1 are under suction pressure, since the variable plate 13 is fitted in between the cavern base 33 of the casing and the casing-cover partition line, forming an axial seal but able to move. The pressure space 35, which is hydraulically connected to the compressing delivery cells of the gear ring running set with the minimum poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com