Paper feed roller

A paper feeding and roller technology, which is used in thin material handling, transportation and packaging, object supply, etc., can solve the problem of difficulty in improving the friction coefficient of friction coatings, and achieve the effect of reducing material costs and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, the best mode for carrying out the present invention will be described.

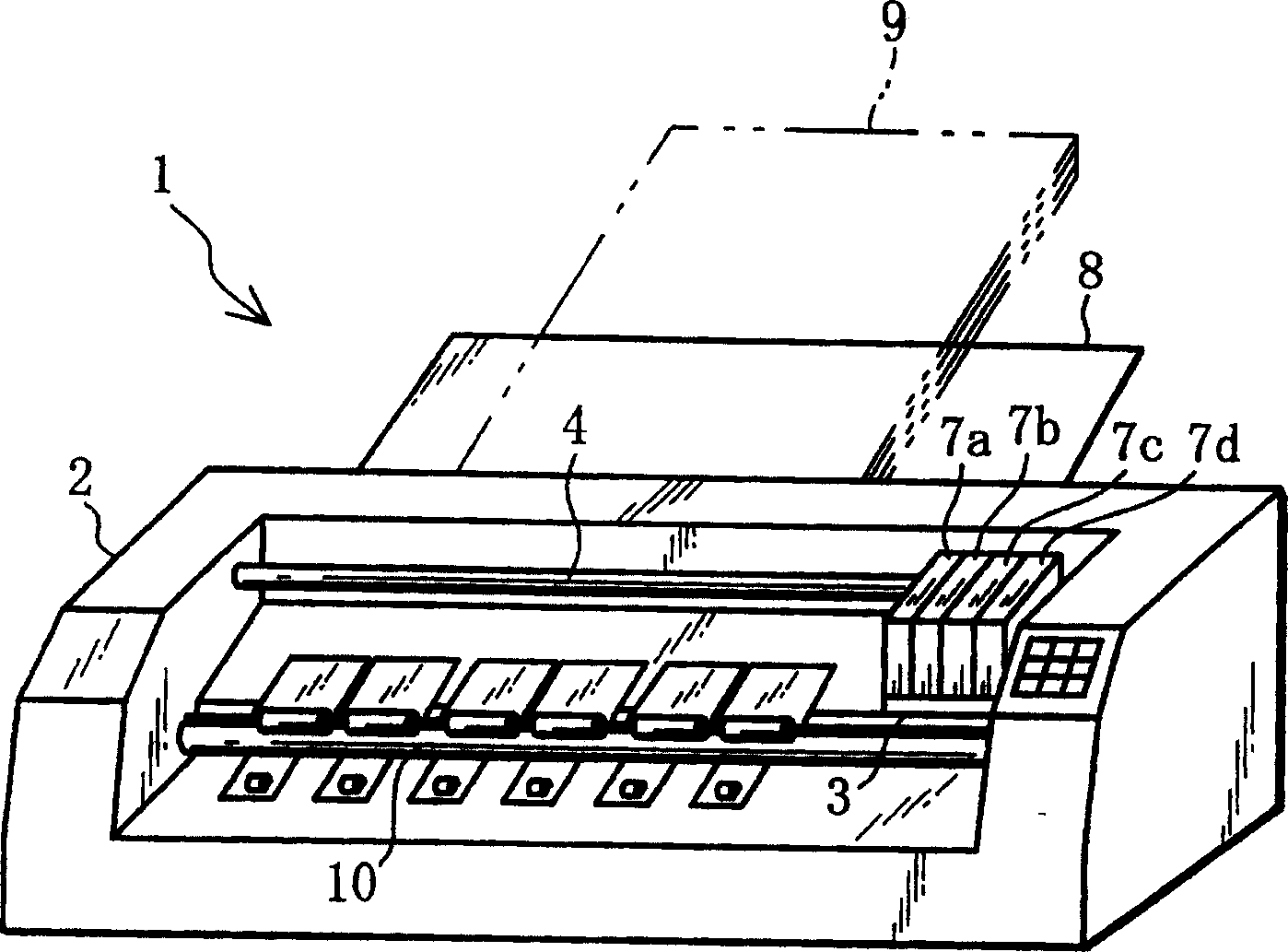

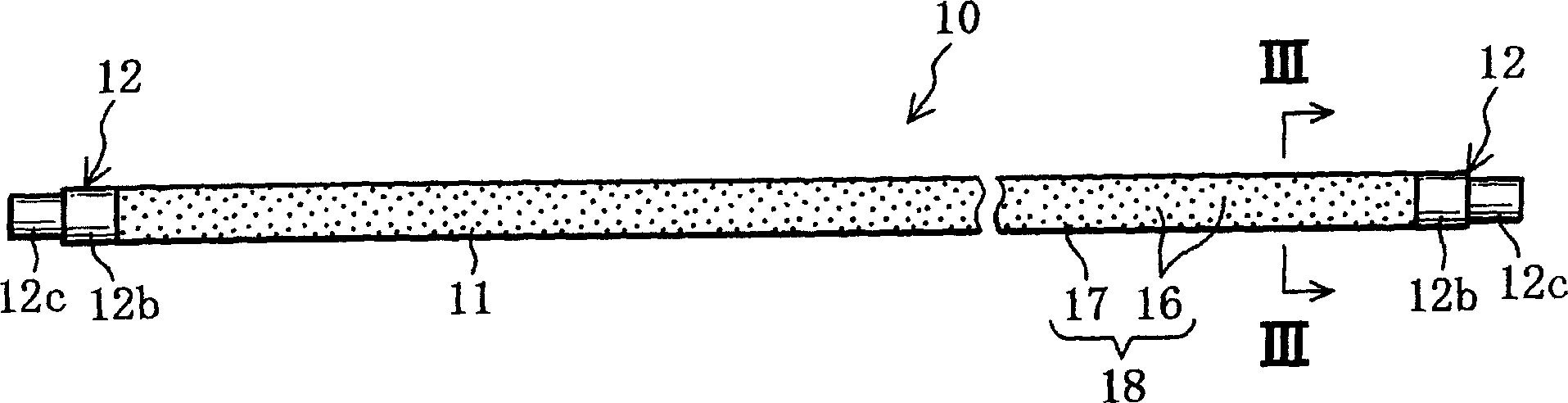

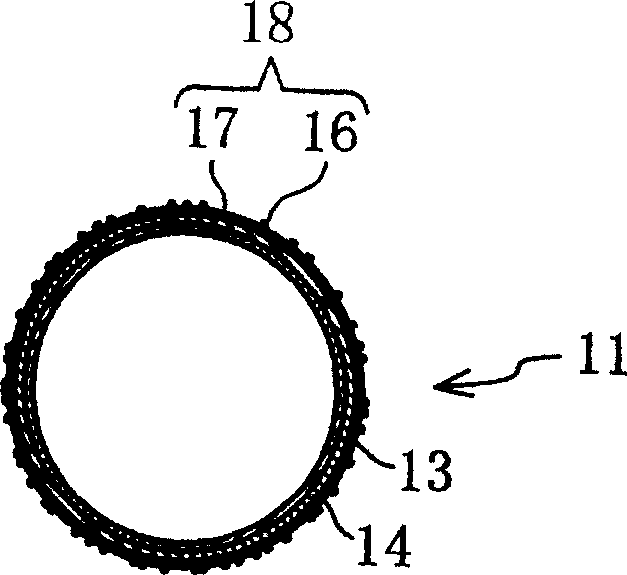

[0051] This embodiment is an example in which the present invention is applied to a paper feed roller for paper feed provided in an inkjet printer and a method of manufacturing the paper feed roller. Such as figure 1 As shown, the printer 1 is an inkjet printer, and the upper part of the main body shell 2 is provided with a moving space for the carriage 3. The carriage 3 is guided and supported by the carriage guide shaft 4, and can move back and forth left and right. The carriage 3 is moved by steps. The motor is driven by a synchronous belt and a pair of pulleys connected with the carriage 3 at both ends. For example, ink cartridges 7 a to 7 d of four colors are detachably attached to the carriage 3 . The paper 9 is fed from the tray 8, fed by the paper feed roller 10 and the pressing roller on the upper side thereof, and printed on the paper by the print head of the carriage 3 wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com