Method of manufacturing molded stator of dynamo electric machine

A technology for molding stators and rotating electrical machines. It is applied in the manufacture of stator/rotor bodies, motor generators, and electromechanical devices. It can solve problems such as chip stress and achieve the effect of reducing stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0037] Embodiment 1 of the manufacturing method of the mold stator of the electric rotating machine of this invention is demonstrated using drawing.

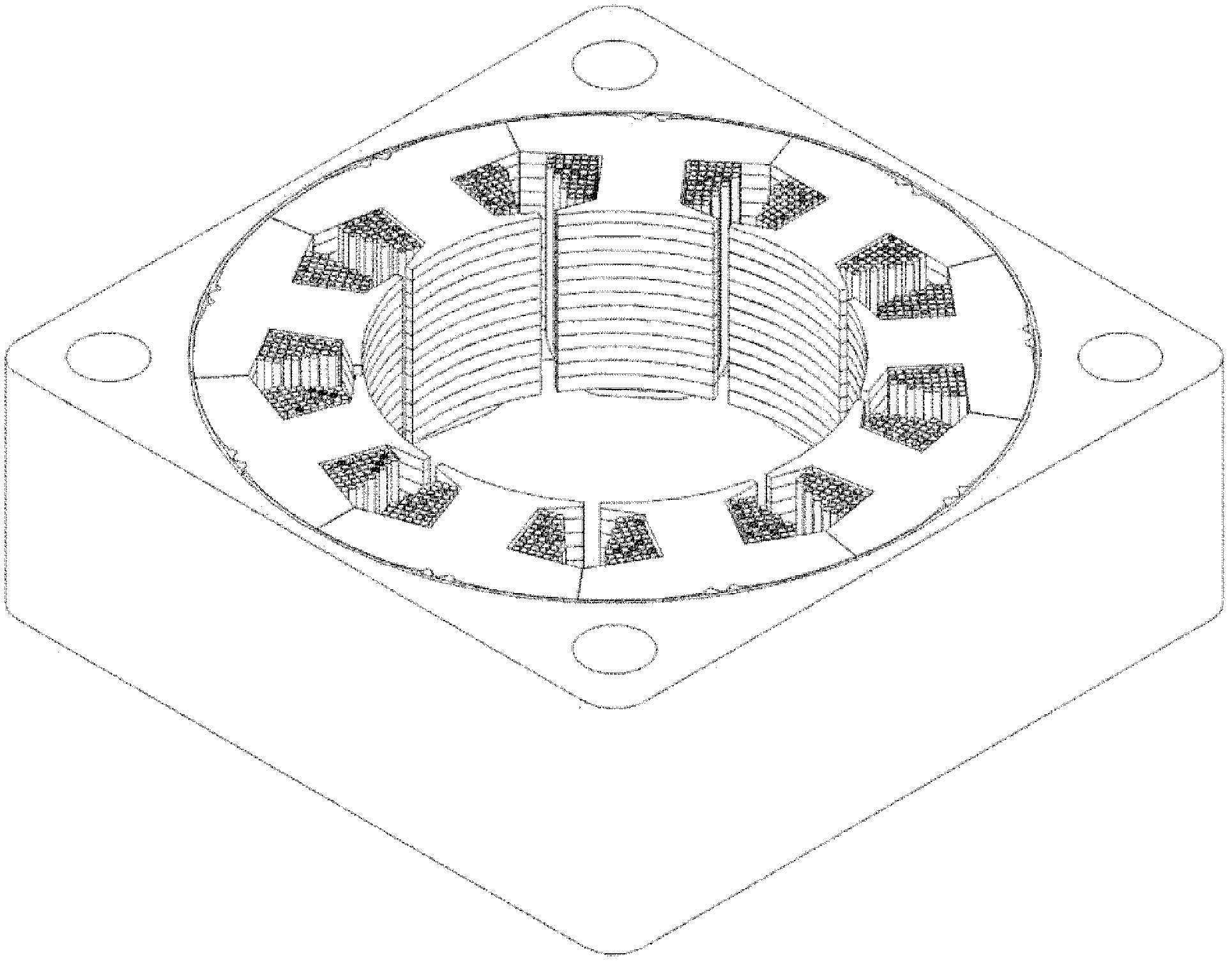

[0038] figure 1 It is a sectional view of the molded stator 1 of the rotating electrical machine of the present invention. Should figure 1 shows a cross section of a molded stator 1 manufactured by combining a plurality of divided laminated cores 71 around which coils 3 are wound in an annular shape and fixing them with film tape 4, and then putting them in Mold and use resin 5 to fix around.

[0039] Hereinafter, the manufacturing method of the molded stator 1 will be described in order.

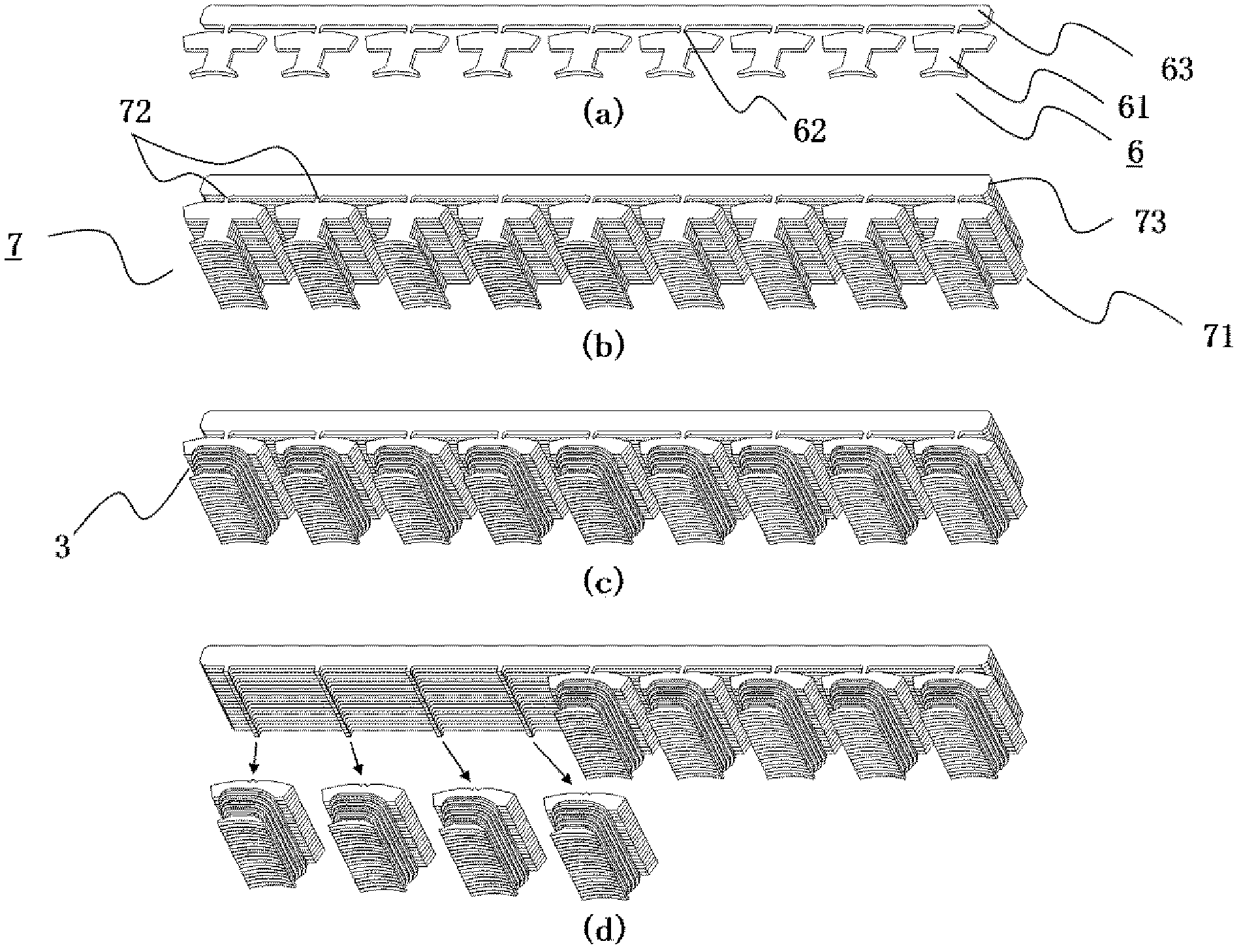

[0040] figure 2 It is a figure showing a lamination process, a winding process, and a cutting process.

[0041] figure 2 (a) is a diagram showing the shape of one core sheet 6 .

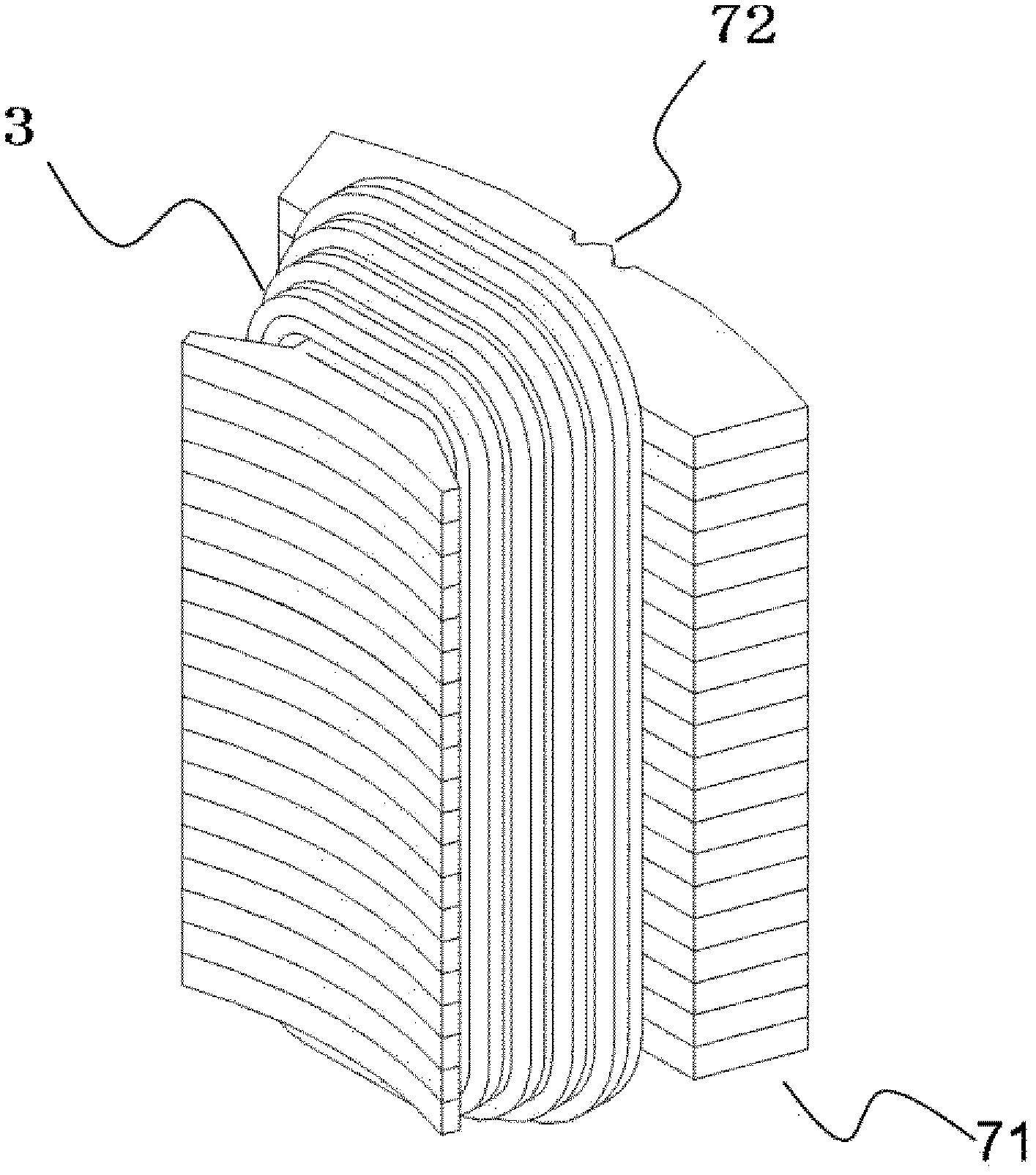

[0042] figure 2 (b) is a diagram showing a divided laminated core group structure 7 in which a plurality of core sheets 6 are laminated.

[0043] figu...

Embodiment approach 2

[0072] Embodiment 2 of the manufacturing method of the molded stator of the electric rotating machine of this invention is demonstrated using drawing.

[0073] In addition, only the parts different from Embodiment 1 will be described, and the common parts will be omitted.

[0074] Figure 7 It is a cross-sectional view of the divided laminated core group structure 107 according to the second embodiment cut along a direction perpendicular to the longitudinal direction and along the lamination direction at a position including the bridge portion 62 .

[0075] In Embodiment 1, a fixing method is employed in which core sheets 6 are directly stacked without providing a member for fitting vertically adjacent core sheets 6 , and coil 3 is wound around the teeth.

[0076] In the present embodiment, recesses 65 are provided on the upper surface of connecting portions 163 of each core sheet, and protrusions 64 are provided on the lower surface.

[0077] exist Figure 7 In the present...

Embodiment approach 3

[0083] Embodiment 3 of the manufacturing method of the mold stator of the electric rotating machine of this invention is demonstrated using drawing. In addition, only the parts different from Embodiment 1 and Embodiment 2 are described, and the common parts are omitted.

[0084] Figure 8 (a) and (b) are figures which show the modification of the concave part and convex part provided in the upper and lower surfaces of the connection part of a core material.

[0085] Figure 9 It is a cross-sectional view in which the lamination connection portion 273 of the divided laminated core assembly structure formed by alternately laminating the core sheets 206 and 2061 along the longitudinal direction and along the lamination direction is divided into two.

[0086] exist Figure 8 On the connecting portion 263 of the core sheet 206 shown on the lower side of (a), convex portions 264 and openings 265 are alternately provided from the right side as shown in the figure.

[0087] In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com