CD-fixing device

A technology for fixing device and optical disc, applied in the directions of optical record carrier and optical record carrier manufacturing, etc., can solve the problems of inability to stabilize the adsorption and positioning of optical disc, difficult to overcome centrifugal force, easy sliding of optical disc, etc. The effect of convenient and quick positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

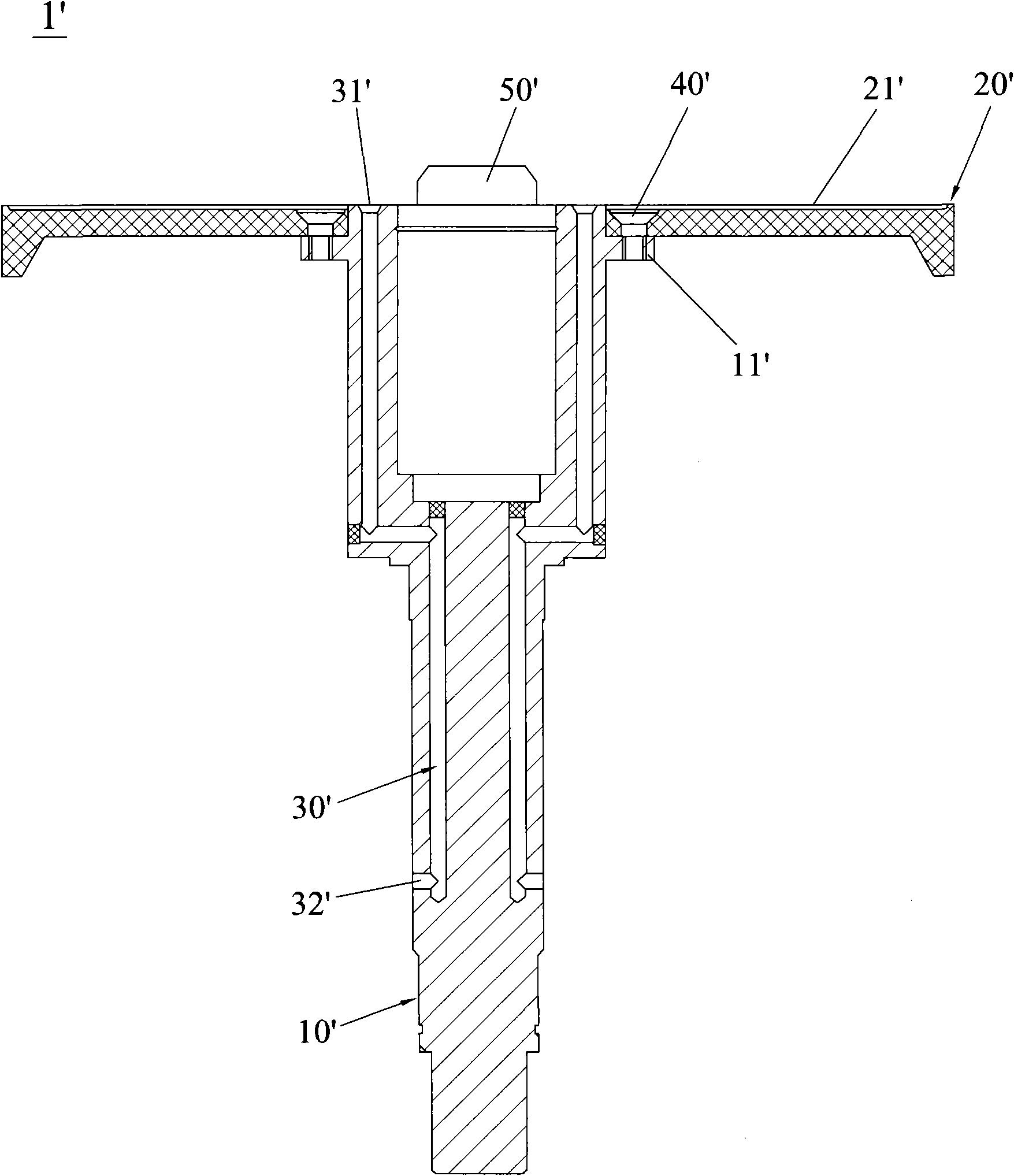

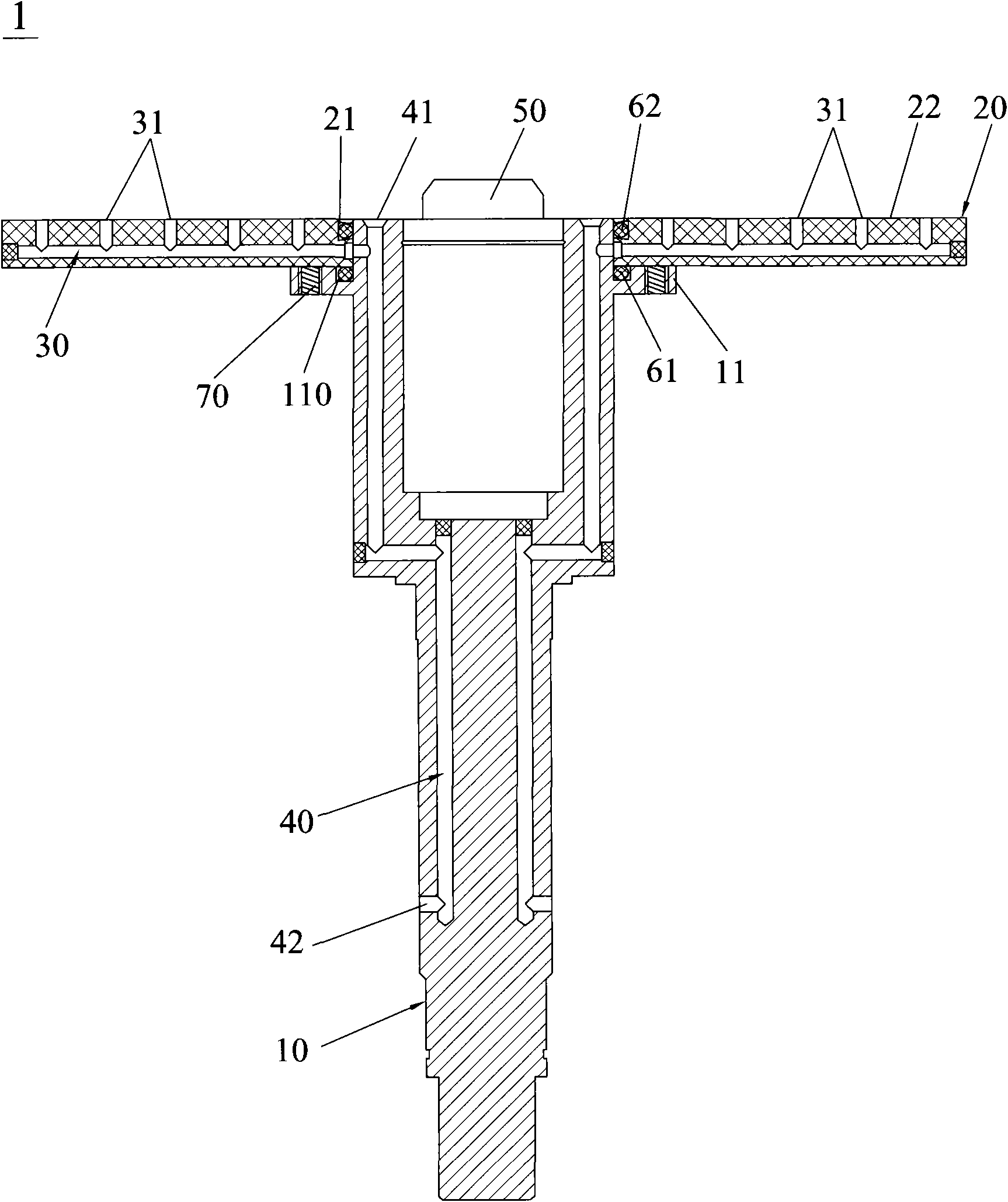

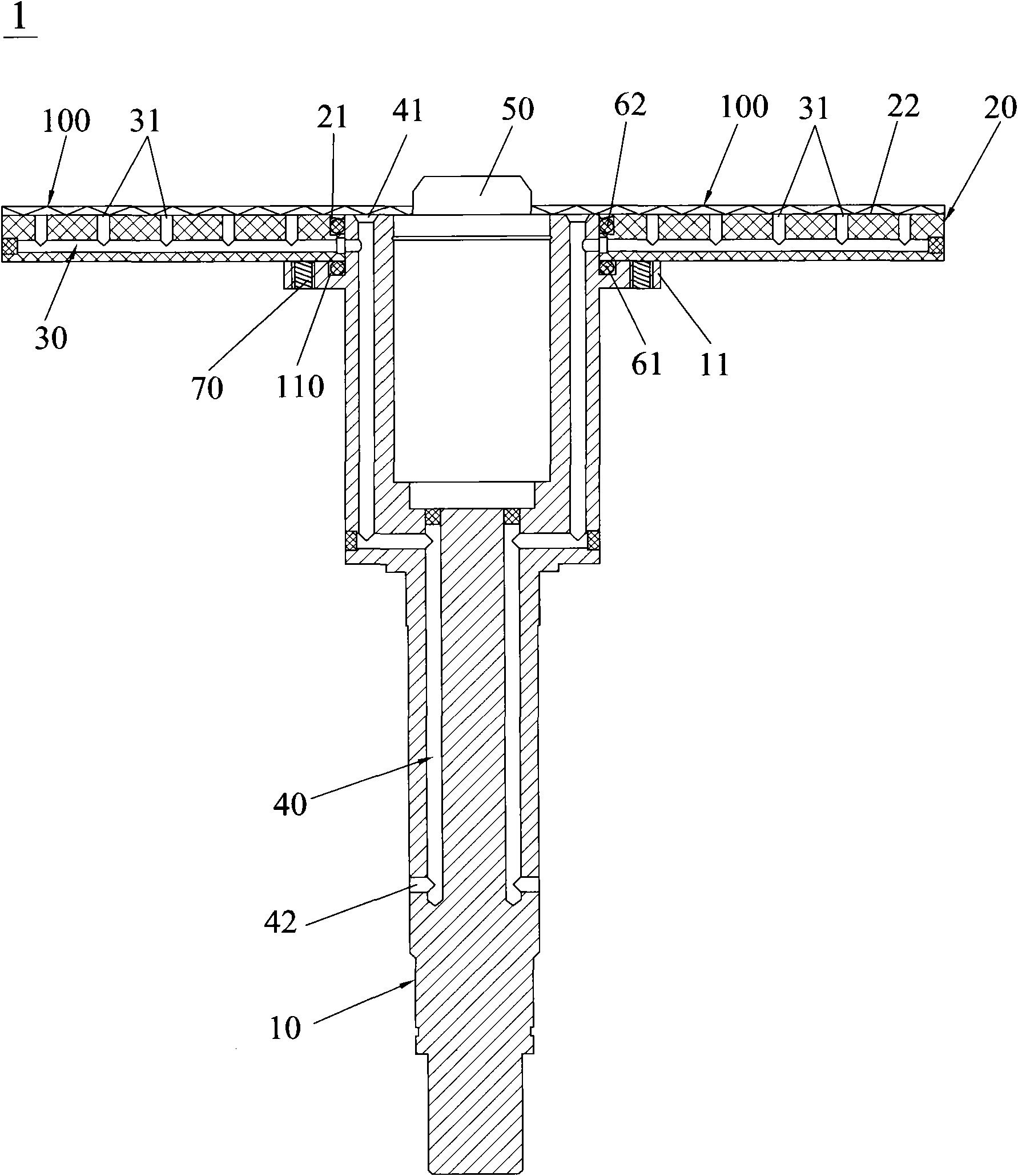

[0016] Such as figure 2 and image 3 As shown, the optical disk fixing device 1 of the present invention includes a turntable 20, a transmission shaft 10 and an adsorption pipeline system. Through the central hole of the turntable 20 and sealed and fixedly connected with the turntable 20, the upper end of the transmission shaft 10 protrudes out a protrusion 50 for the optical disc 100 to pass through, and one end of the adsorption pipeline system runs through the turntable The upper surface 22 of 20 is located on the same plane as the upper surface 22, and the other end of the adsorption pipeline system penetrates the transmission shaft 10 and passes through the transmission shaft 10 and the external vacuum device (not shown in the figure). ), the external drive device drives the transmission shaft 10 to rotate, and the transmission shaft 10 drives the turntable 20 to rotate. The adsorption pipeline system includes a number of side vacuum pipelines 30 and a central vacuum pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com