Optical recording medium-producing sheet and optical recording medium

A technology for optical recording media and sheets, which is applied in the field of optical recording media manufacturing sheets for recording media, can solve problems such as inability to reproduce recorded information correctly, and achieve the effects of suppressing degradation, reducing cross-erasing, and suppressing fusion areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

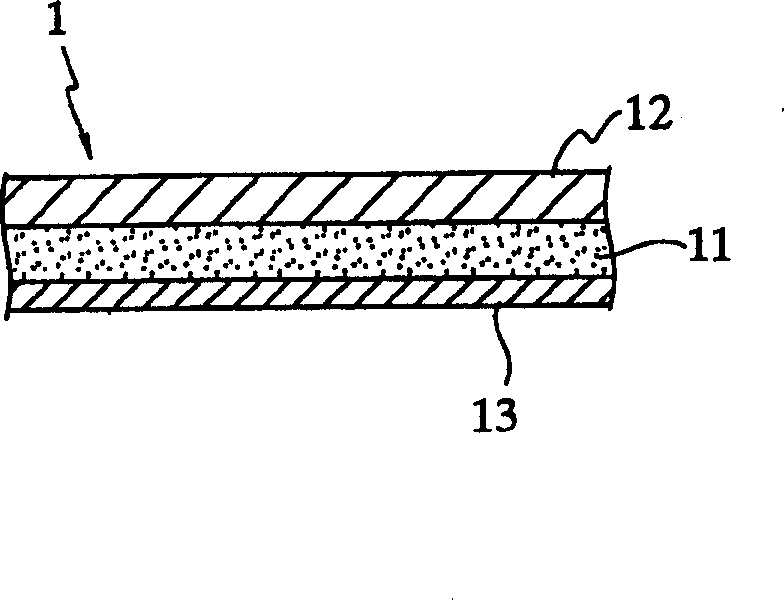

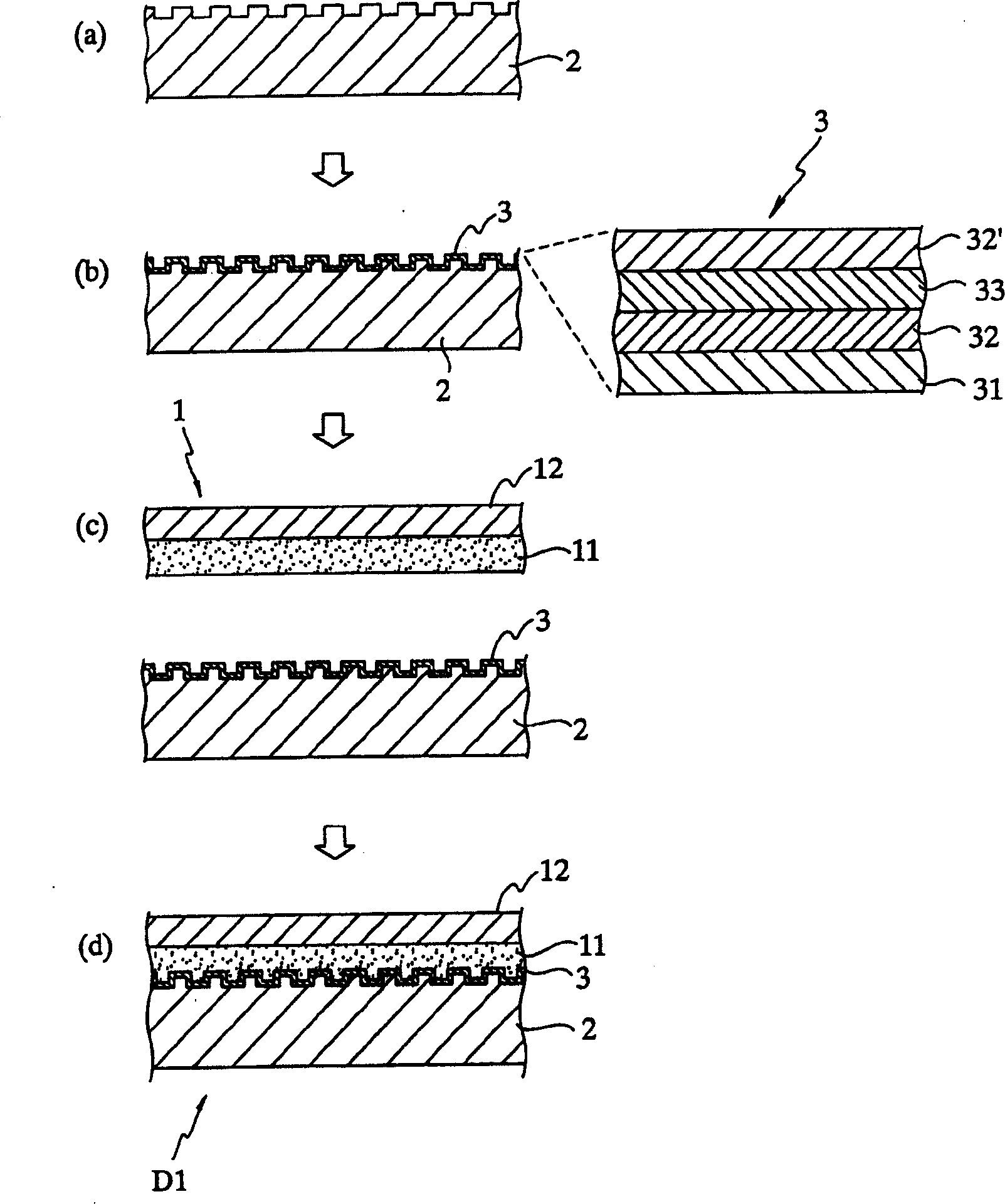

[0033] In the first embodiment, an optical disc manufacturing sheet for forming a protective sheet for an optical disc which is a writable optical recording medium will be described. figure 1 is a cross-sectional view of a sheet for manufacturing an optical disc according to the first embodiment of the present invention, figure 2 (a)~ figure 2 (d) is a cross-sectional view showing an example of an optical disc manufacturing method using the optical disc manufacturing sheet of this embodiment.

[0034] like figure 1 As shown, the optical disc manufacturing sheet 1 of the first embodiment has an adhesive layer (curable layer) 11, and one surface of the adhesive layer 11 ( figure 1 The protective sheet (protective layer) 12 laminated on the top of the middle), and the other side of the adhesive layer 11 ( figure 1 Middle and lower surfaces) are laminated with a release sheet 13. In addition, the protective sheet 12 is a protective layer of an optical disk, and the peeling s...

no. 2 Embodiment approach

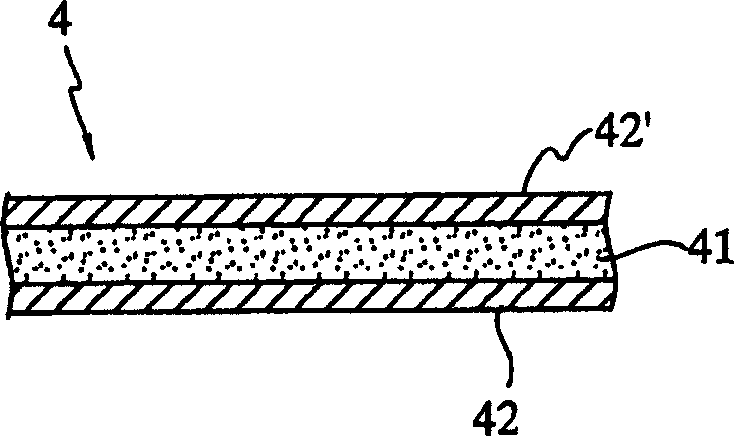

[0093] In the second embodiment, an optical disk manufacturing sheet including a stamper-receiving layer for replicating the concavo-convex pattern of the stamper will be described. image 3 is a cross-sectional view of a sheet for manufacturing an optical disc according to a second embodiment of the present invention, Figure 4 (a)~ Figure 4 (g) is a sectional view which shows an example of the manufacturing method of the optical disc using the optical disc manufacturing sheet of this embodiment.

[0094] like image 3 As shown, the optical disc manufacturing sheet 4 of the second embodiment is composed of a stamper-receiving layer (curable layer) 41 and release sheets 42, 42' laminated on both sides of the stamper-receiving layer 41 . Among them, the release sheets 42, 42' are peeled off when the sheet 4 for optical disc manufacturing is used.

[0095] The stamper-receiving layer 41 is a layer that reproduces the concave-convex pattern formed on the stamper, constitutes ...

no. 3 Embodiment approach

[0113] In the third embodiment, an optical disc manufacturing sheet including a stamper-receiving layer on which the concavo-convex pattern of the stamper has been copied and the two A sheet for manufacturing an optical disc in which information recording layers are bonded to each other. Figure 5 (a), Figure 5 (b) is a cross-sectional view of a sheet for manufacturing an optical disc according to a third embodiment of the present invention, Image 6 (a)~ Image 6 (e) is a sectional view showing an example of an optical disc manufacturing method using the optical disc manufacturing sheet of this embodiment.

[0114] like Figure 5 As shown in (a), the first optical disc manufacturing sheet 5 of this embodiment is formed of a stamper receiving layer (curable layer) 51, laminated on one surface of the stamper receiving layer 51 ( Figure 5 The protective sheet (protective layer) 52 on the middle upper surface), and the other side laminated on the stamper receiving layer 51 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com