Optical disc manufacturing method, disc master manufacturing method, and optical disc

A manufacturing method and optical disc technology, applied in the direction of optical record carrier manufacturing, optical record carrier, etc., can solve the problem of increasing resolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Embodiments of the present invention will be described according to the following order:

[0064] [1. Disc manufacturing process],

[0065] [2. Mastering using inorganic resist],

[0066] [3. The disc to be manufactured], and

[0067] [4. Verification]

[0068] [1. Disc manufacturing process]

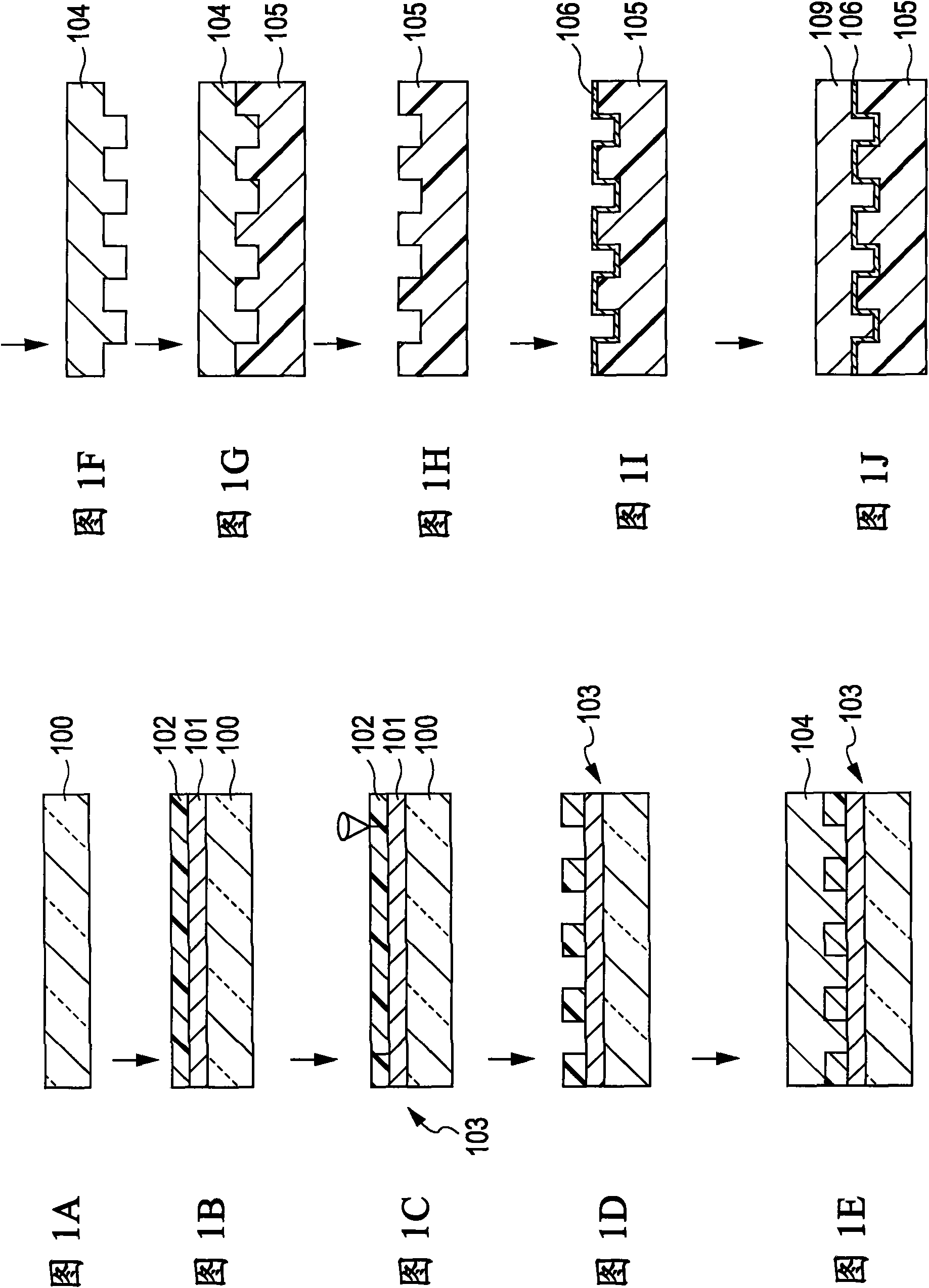

[0069] First refer to Figure 1A ~ Figure 1J A schematic diagram is shown to describe the process used to manufacture an optical disc.

[0070] Figure 1A A master forming substrate 100 providing a disc master is shown. For example, the mastering substrate 100 may be made of a silicon wafer or quartz.

[0071] Such as Figure 1B As shown, a heat storage layer 101 and an inorganic resist layer 102 are deposited on a master forming substrate 100 by sputtering.

[0072] Next, if Figure 1C As shown, the resulting resist layer is photosensitive by performing selective exposure corresponding to the pit array (used as a recording signal pattern) on the inorganic resist layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com