Optical disc producing device and producing method

A technology for manufacturing equipment and manufacturing methods, applied in the direction of optical record carrier manufacture, optical recording/reproduction, optical record carrier, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

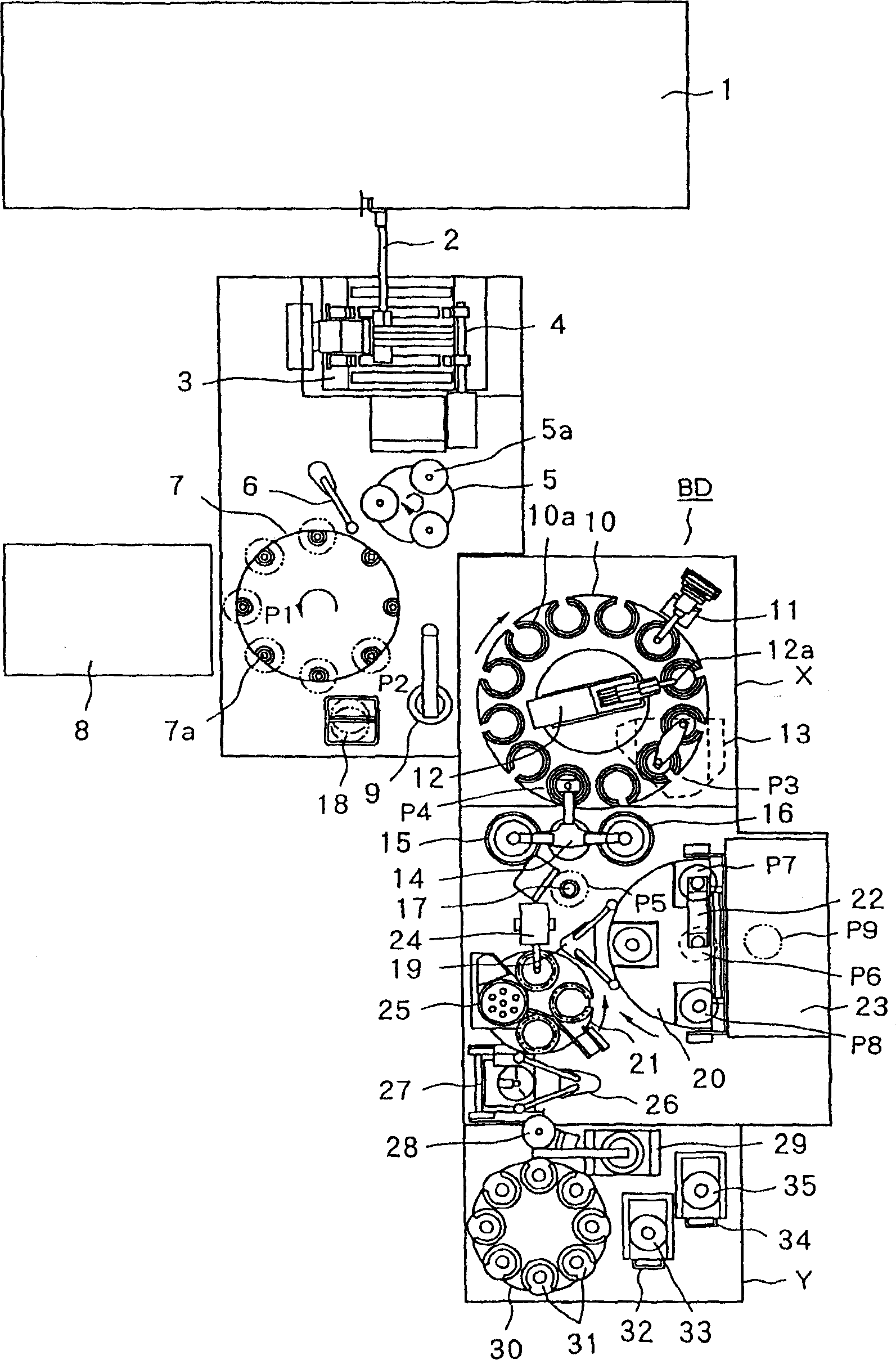

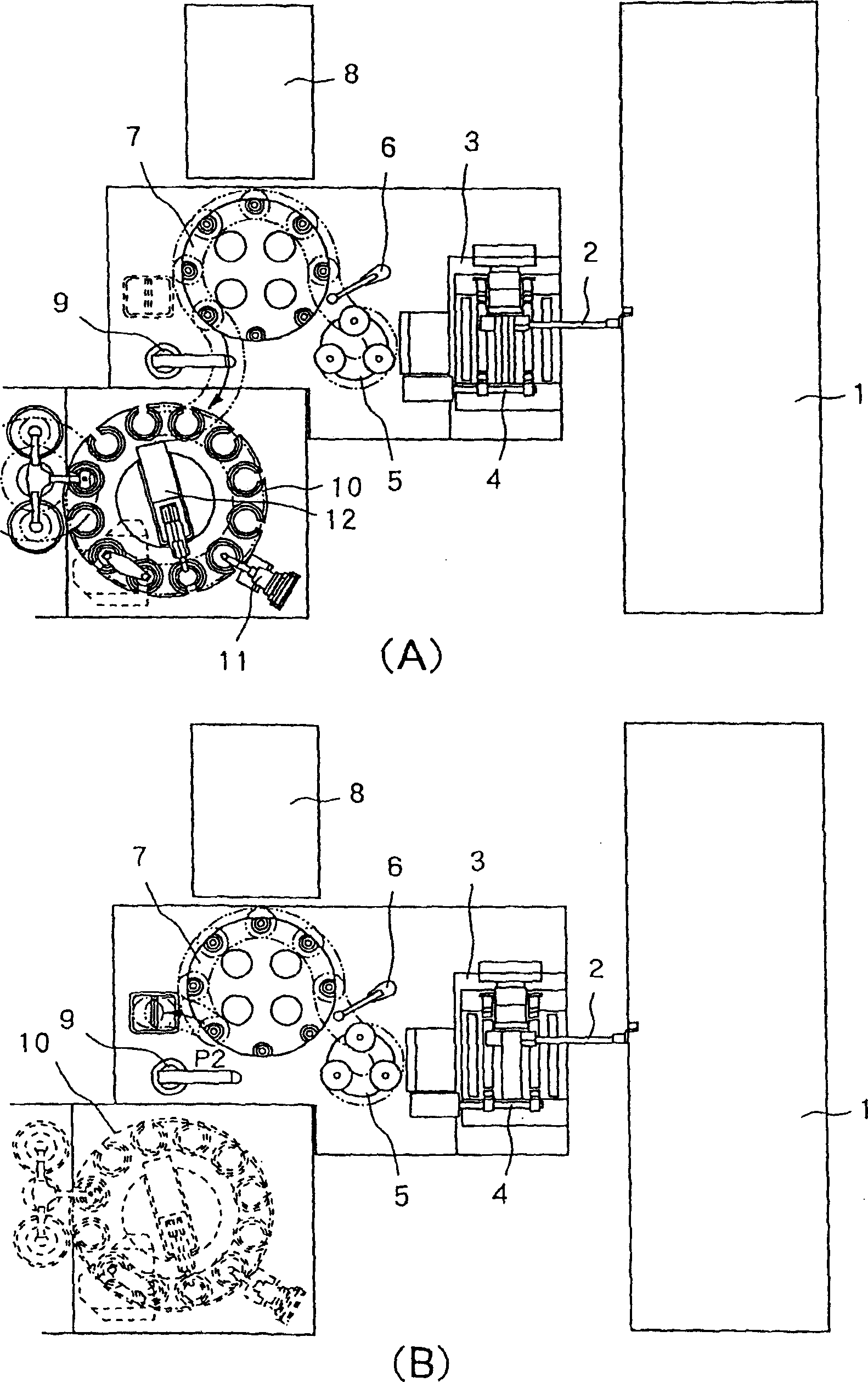

[0033] First, refer to figure 1 A preferred embodiment of an optical disc manufacturing device of the present invention corresponding to an optical disc manufacturing method according to the present invention is described, wherein figure 1 A rough layout of the optical disc manufacturing facility is shown.

[0034] figure 1 In, reference numeral 1 denotes a molding machine (manufactured by Kabushiki Kaisha MEIKI Co., Ltd.) capable of simultaneously forming two disk substrates having different information recorded on each surface thereof.

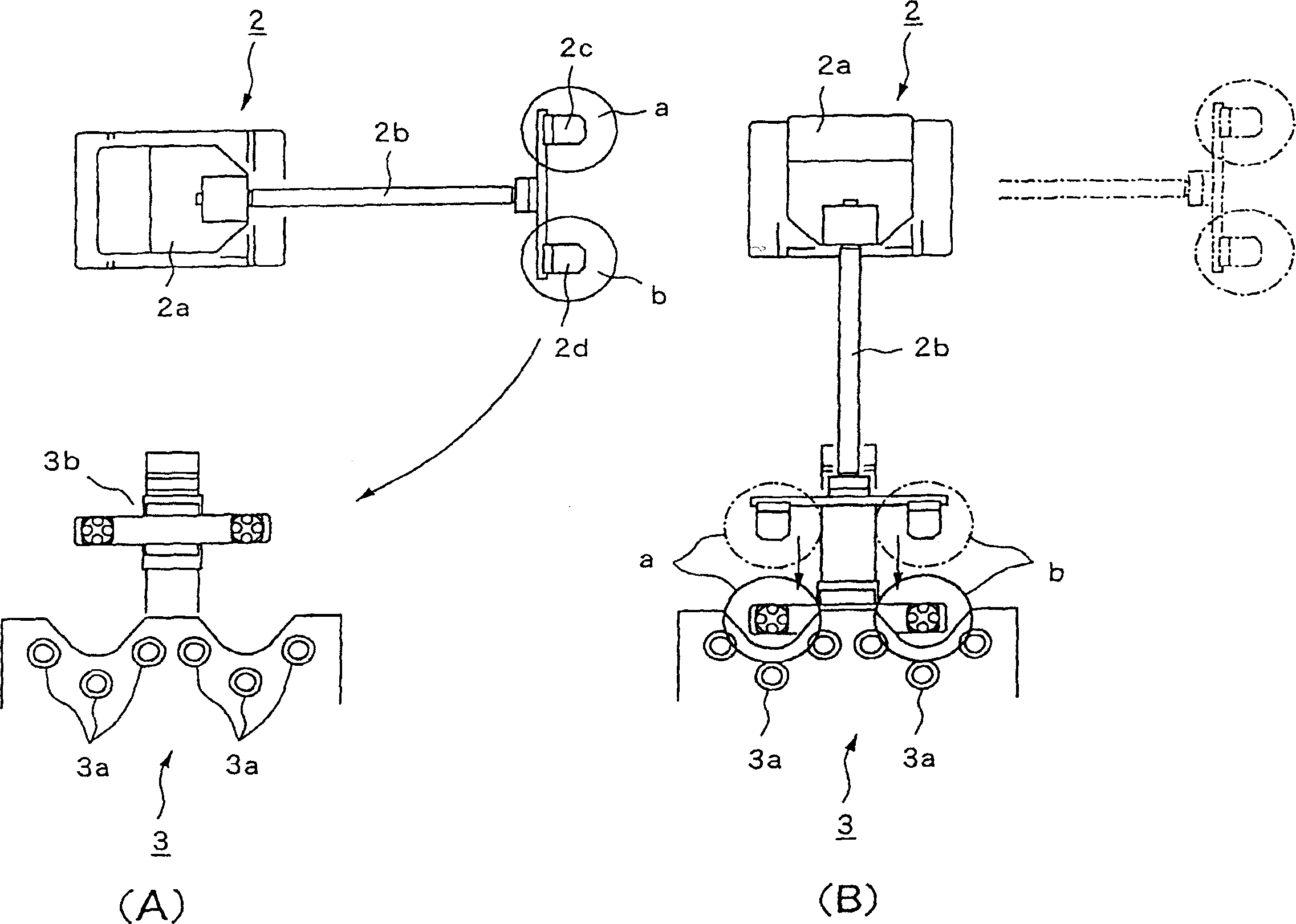

[0035] The mobile placement device 2 comprises a mobile placement arm and its drive unit. The moving setter 2 simultaneously sucks, holds and accepts two disk substrates delivered from the molding machine 1, rotates them in a substantially vertical direction and sets them on a cooling mechanism 3 which will be described in detail later.

[0036] Since the temperature of each molded disc substrate is high, the cooling mechanism 3 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com