Parallel-series principle milling vehicle combined numerically controlled machine

A composite CNC machine tool and hybrid technology, applied in metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc., can solve the problems of weakened rigidity, increased machine tool weight, large machine tool stroke, etc., to expand the size of turning processing range, the effect of improving the Z-direction motion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

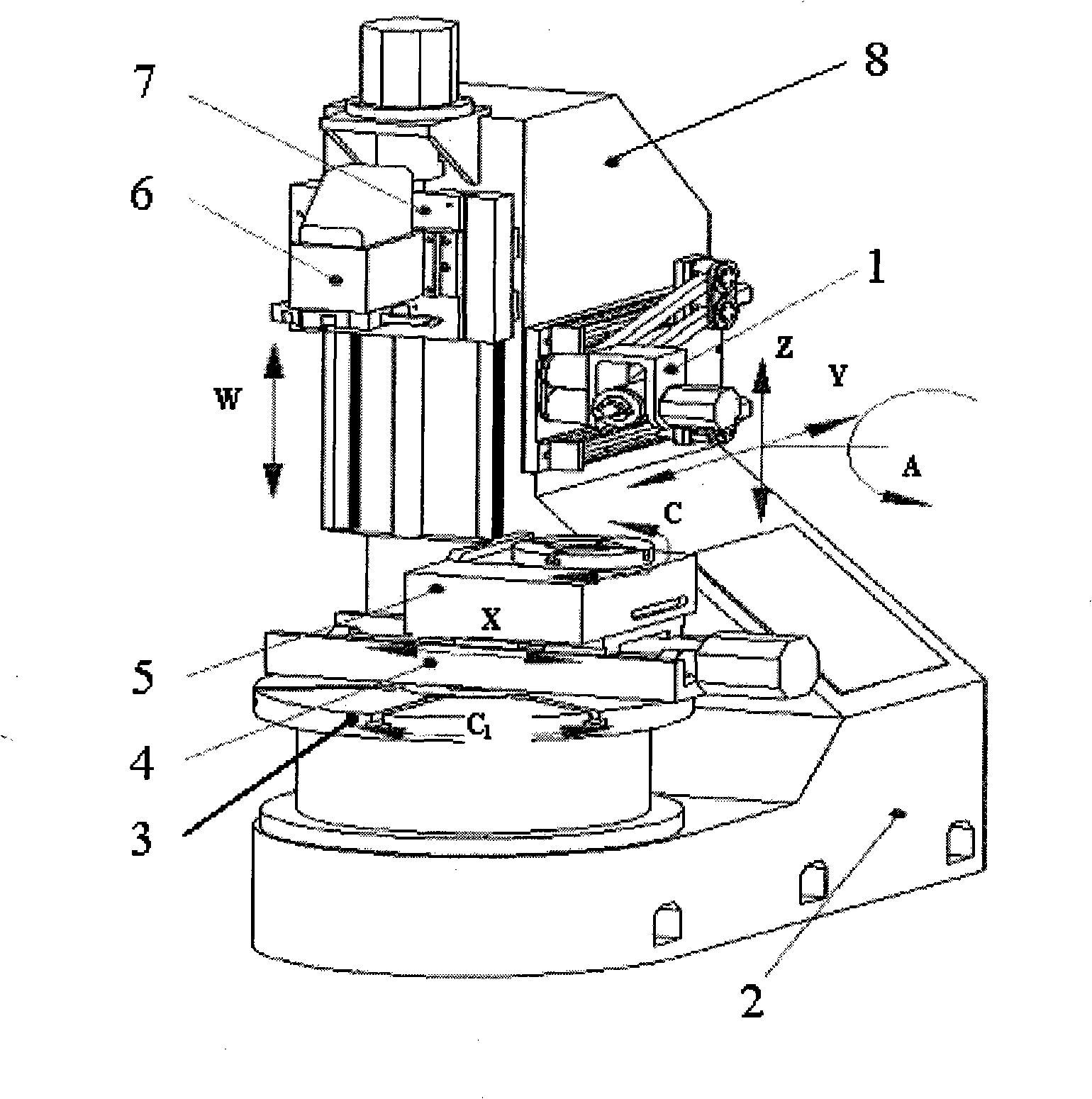

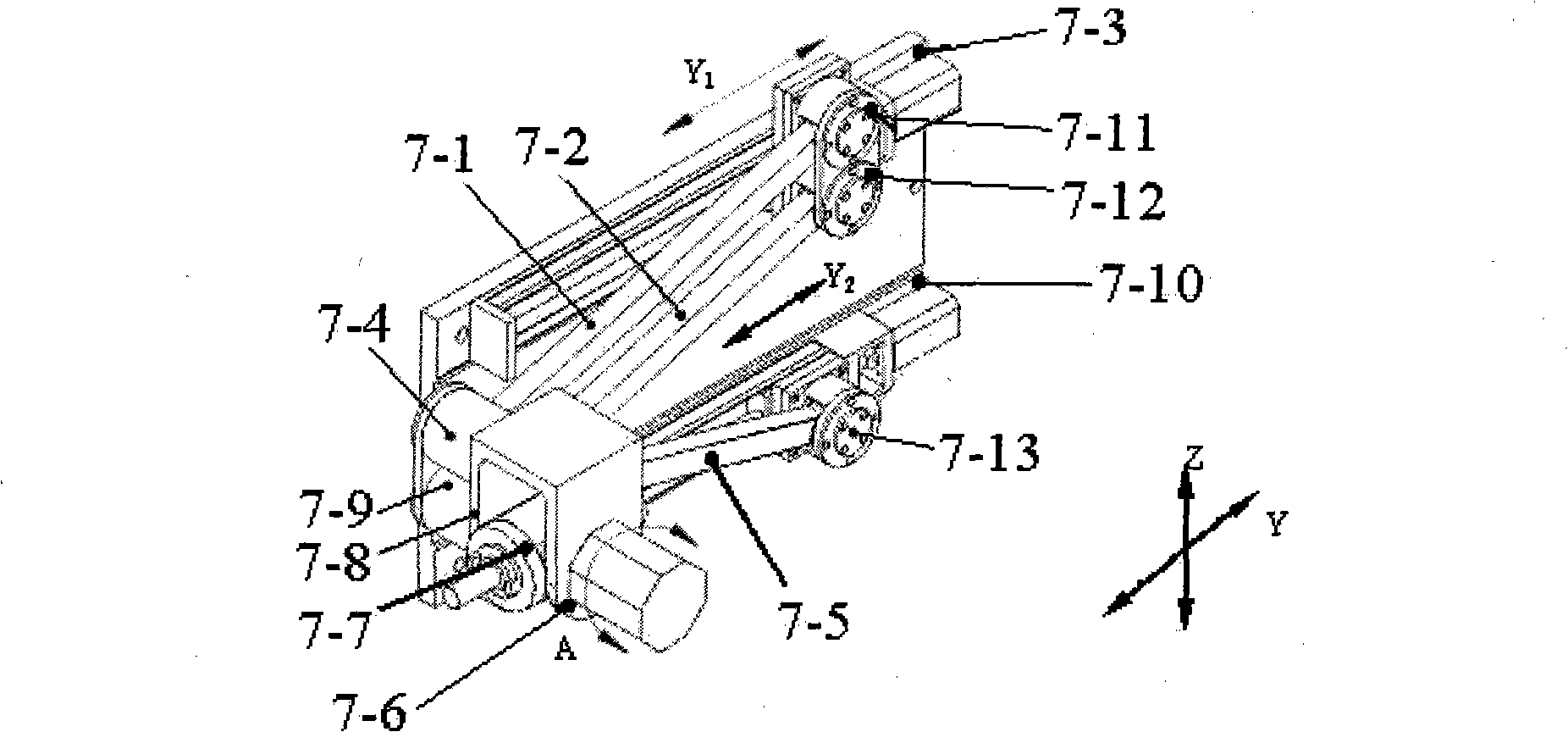

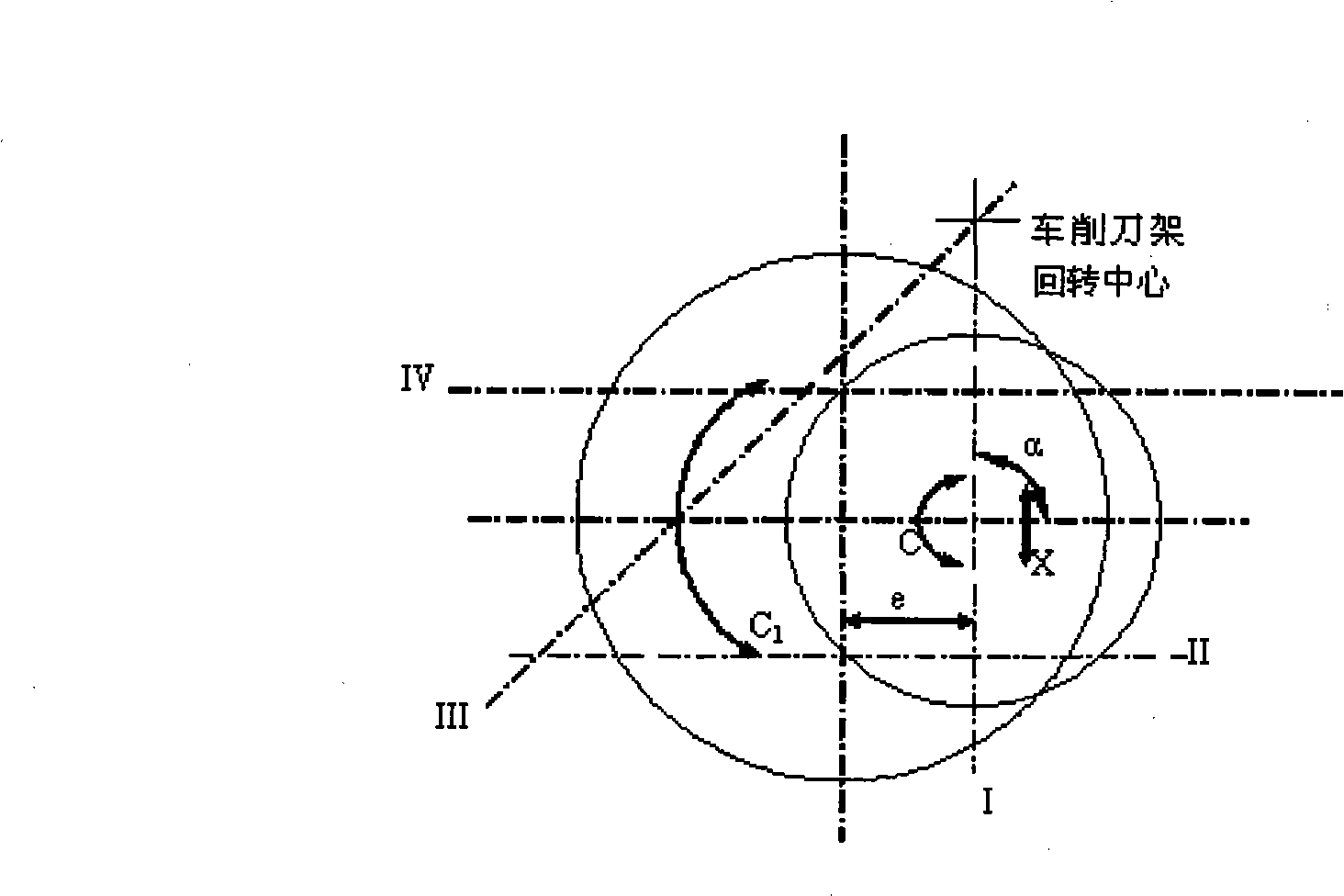

[0035] The overall structure of an embodiment of the composite CNC machine tool of the present invention is as follows: figure 1 shown. The machine tool consists of a three-axis mixed milling spindle head 1, a bed 2, an indexing turntable 3, an X-axis assembly 4, a C-axis rotary table assembly 5 and a column 8. Y of the moving pair of the two-axis parallel mechanism in the three-axis hybrid milling spindle head 1 1 , Y 2 Movement, the X-direction movement of the X-axis assembly 4 and the Z-direction movement of the W-axis are driven by a servo motor through a ball screw pair.

Embodiment 2

[0037] Similar to the implementation method of Embodiment 1, the difference is that the Y of the moving pair of the two-axis parallel mechanism is 1 , Y 2 The movement and X-direction movement of the X-axis assembly 4 is directly driven by a linear motor to meet the needs of high-precision and high-speed machining. In addition, a standard floor-mounted tool magazine is also configured to meet the needs of quick tool change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com