Flexible manufacturing system experimental equipment based on industrial robots

A technology of flexible manufacturing systems and industrial robots, which can be applied to aerospace equipment, instruments, simulators, etc., and can solve problems that are difficult to adapt to the needs of the market economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

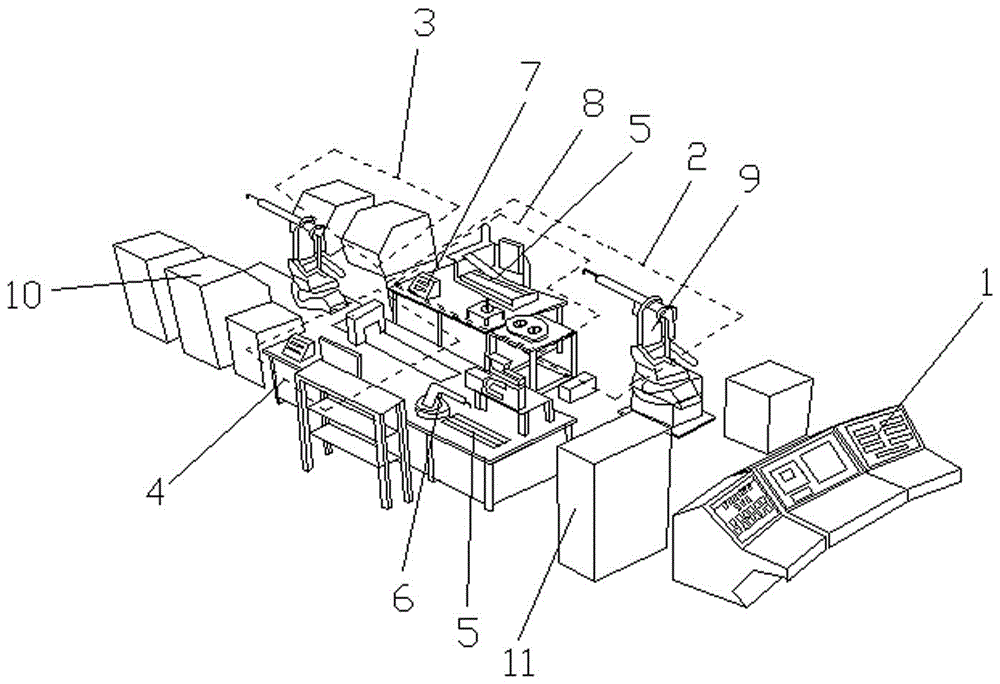

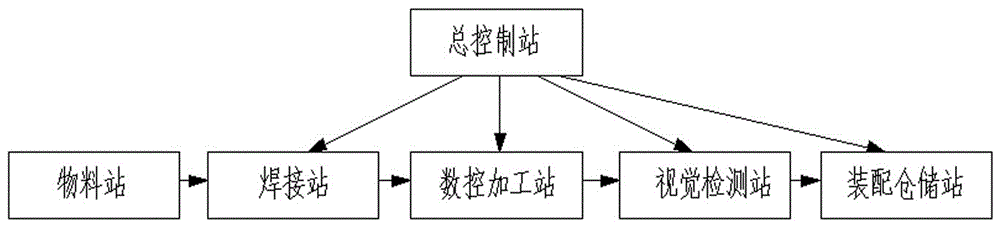

[0022] Referring to the figure, a flexible manufacturing system experimental equipment based on industrial robots is composed of five modules: a total control station 1, a welding station 2, a numerical control processing station 3, a visual inspection station 4 and an assembly storage station 11. The total control station 1 is connected with other stations through the CClink network. The total control station 1 includes a PLC master console and a conveying device controlled by the PLC master console. The conveying device has a conveying track 5, and the conveying track 5 On the machine bed loading and unloading robot is installed. The machine tool loading and unloading robot is controlled by the stepping motor to move horizontally on the conveying track 5 to complete the work of transporting the workpiece from the material station 8 to the welding stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com