Automatic control device for punching machine production line

An automatic control device and production line technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high cost and difficult cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

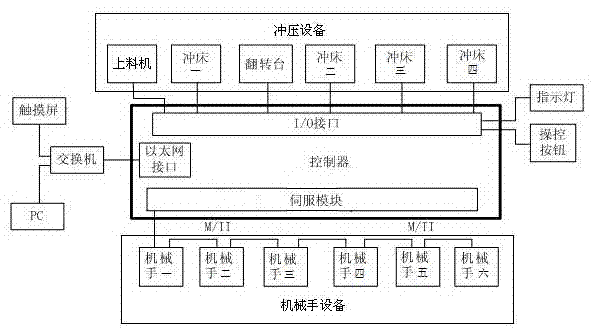

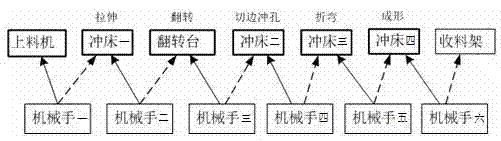

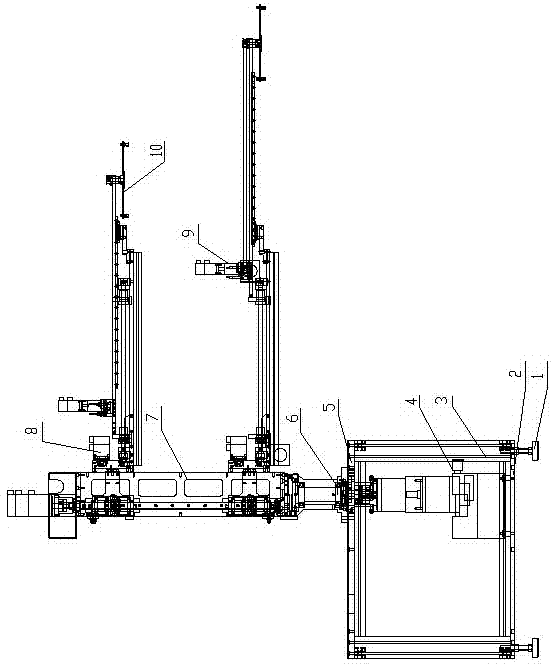

[0048] Such as Figure 1~20 As shown, an automatic control device for a press production line includes a controller, a stamping mechanism and a control mechanism. The signal output terminal of the controller is electrically connected to the signal input terminal of the stamping mechanism and the control mechanism. The stamping mechanism and the control mechanism are divided into two rows, opposite to each other. Setting, the first row is the stamping mechanism, and the stamping mechanism is arranged in sequence with the feeding machine, the first punch press, the turning table, the second punch press, the third punch press, the fourth punch press and the receiving rack, and the second row is the control mechanism. The mechanism includes six manipulators, and the first manipulator, the second manipulator, the third manipulator, the fourth manipulator, the fifth manipulator and the sixth manipulator are arranged in sequence, and the input and output signal control terminals of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com