Mechanical control device with cross position changing function and control method of control device

A mechanical control and functional technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high cost and difficult cooperation, achieve the effect of remote control and meet the requirements of product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

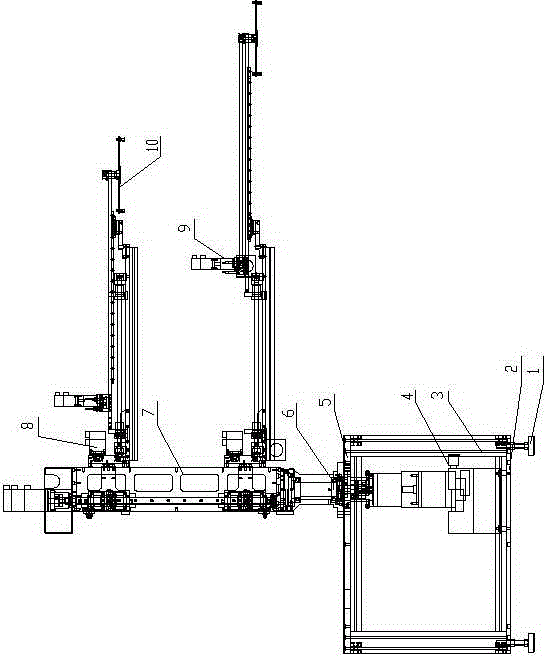

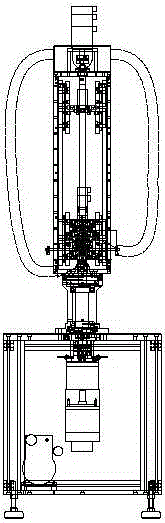

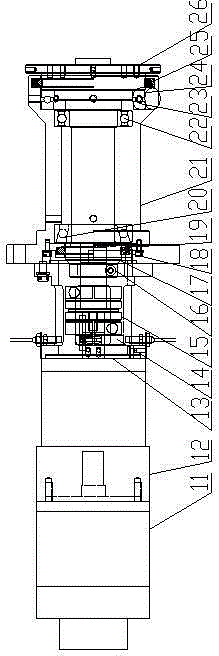

[0051] A mechanical control device with a cross-transposition function, including a controller, multiple punches and multiple manipulators, the input and output signal control terminals of the punches are electrically connected to the I / O interface of the controller, and the input and output signals of the manipulators are controlled The terminal is electrically connected to the controller through the M / II bus. Multiple punches are set in a row, and multiple manipulators are set in a row. It is removed by one punch and put into the next punch.

[0052] like figure 1 , 2 As shown, the manipulator includes a brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com