Object-oriented Petri network modeling method in flexible manufacturing system

A flexible manufacturing system, object-oriented technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as inability to change, system conflicts, difficulties in building models and changing models, and avoid deadlocks and conflicts , easily refactorable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

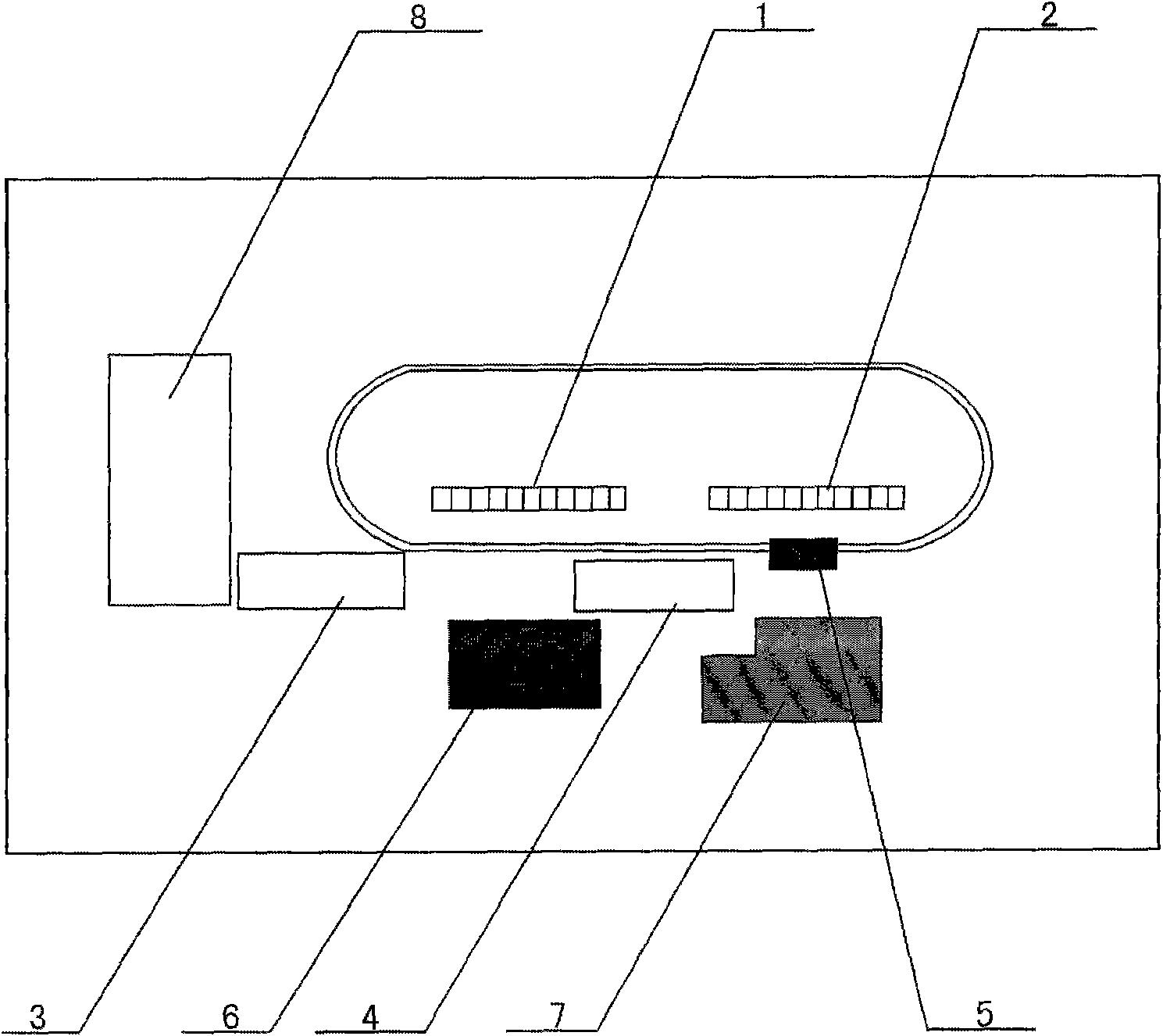

[0061] Such as figure 1 As shown, the FMS layout includes buffer zone 1, buffer zone 2, manipulator 3, manipulator 4, AGV trolley 5, HASS CNC lathe 6, XH-714 CNC milling machine 7, loading and unloading station 8, and two processing machines: HASS CNC Lathe 6 and XH-714 CNC milling machine 7, there is a six-station buffer zone 1 in front of HASS CNC lathe 6, and a six-station buffer zone 2 in front of XH-714 CNC milling machine 7; there is one on the side of the buffer zone for loading and unloading station 8; the buffer zone places an AGV trolley 5 with two stations for transferring and placing parts on the flexible production line; manipulator 3 and manipulator 4 are respectively placed on HASS CNC lathe 6 and XH-714 CNC milling machine 7 ex.

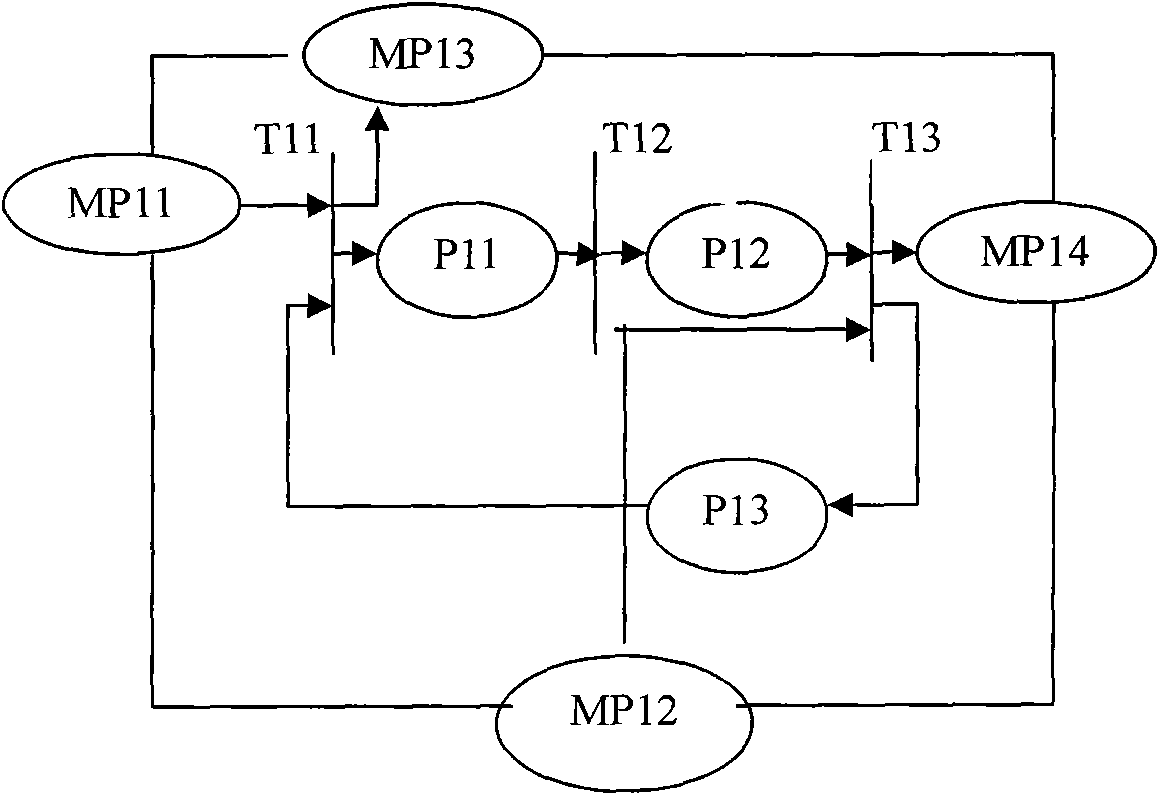

[0062] Such as figure 2 As shown, the parts are sent to the machine tool by the AGV trolley for processing and placed in the buffer zone of the machine tool. If the machine tool 1 is free P13 and there is a part MP11 in the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com