3D environment surface triangular mesh constructing method based on 2D laser sensor

A triangular grid and two-dimensional laser technology, applied in the field of laser point cloud-based environmental modeling, can solve problems such as difficult to construct triangular elements, affect the effect of triangular grids, and uneven point cloud data, and achieve processing Fast speed, easy handling, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

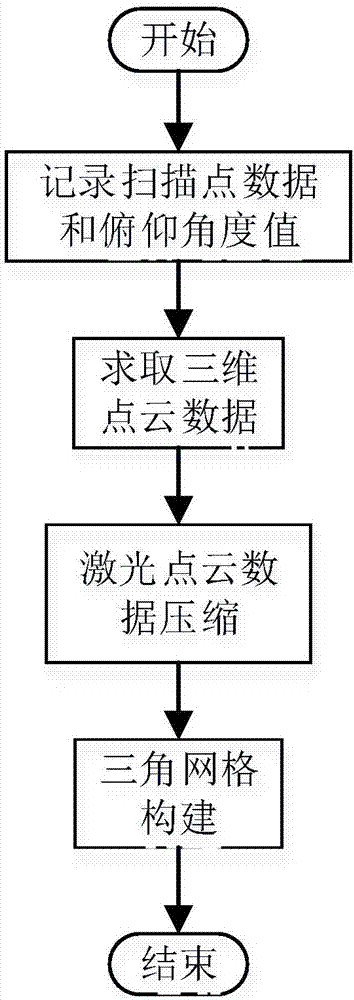

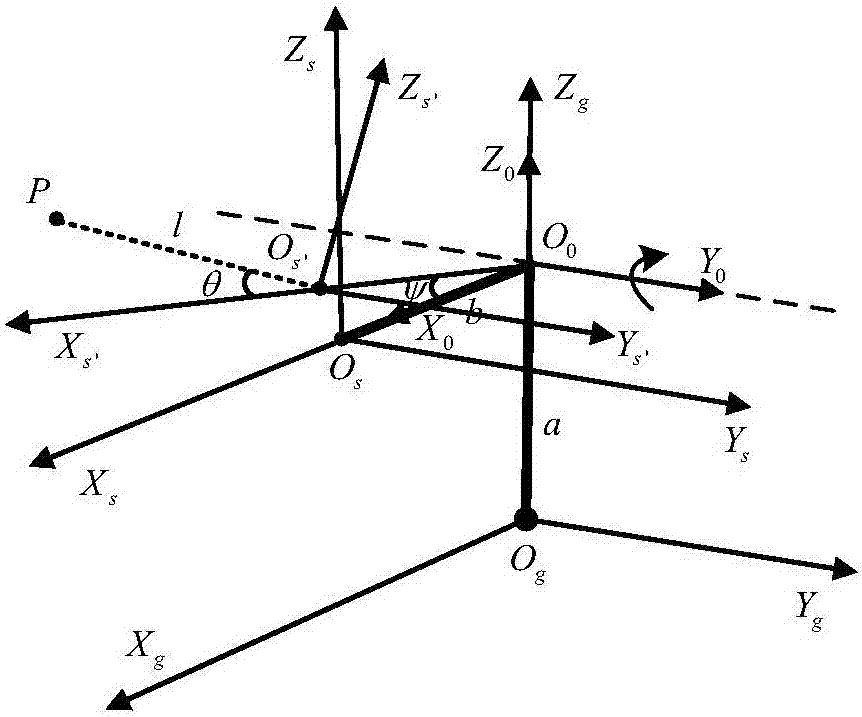

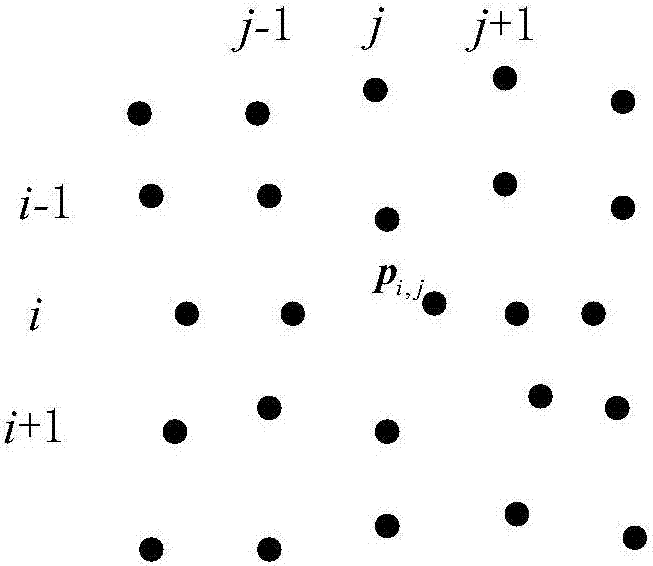

[0037] The realization principle of the present invention is as follows: firstly, a three-dimensional laser scanner is built by using a one-dimensional pitch-rotating pan-tilt and a two-dimensional laser sensor, and a Cartesian coordinate system is established. Use the host computer software to record the scanning data of the two-dimensional sensor and the rotation angle value of the one-dimensional pitch-rotating head. Then through coordinate transformation, the distance value, deflection angle value and pitch angle value recorded by the host computer are converted to the three-dimensional space Cartesian coordinate system, and the uniform sampling method is used to realize the compression of the three-dimensional point cloud data. Number the compressed 3D point cloud data to turn it into a point cloud matrix. In order to realize the triangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com