Energy-consumption-oriented cavity numerical control milling cutter combination optimization method

A technology for CNC milling and machining tools, applied in the field of machining, which can solve the problems of high energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it should not be understood that the scope of the subject matter of the present invention is limited to the following embodiments. Without departing from the above-mentioned technical ideas of the present invention, various replacements and changes made according to common technical knowledge and conventional means in this field shall be included in the protection scope of the present invention.

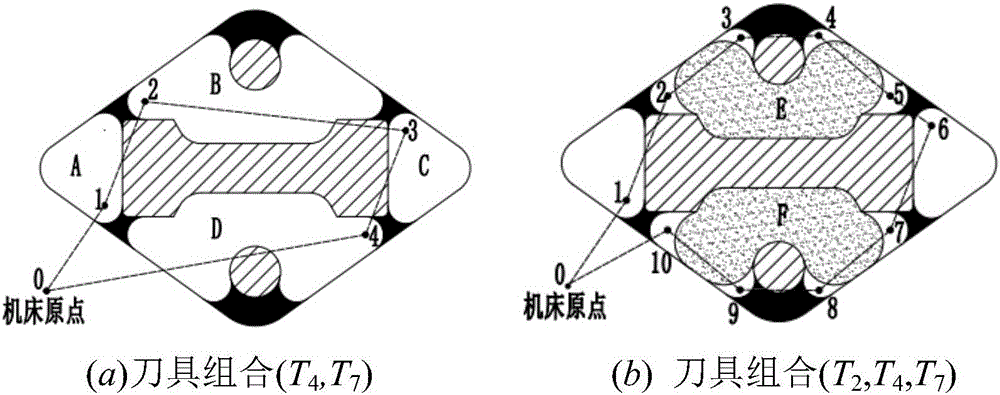

[0100] This embodiment takes Prius PL700 machining center as platform, to Figure 7 The tool combination shown in the 2.5D cavity milling process was optimized for selection. The machine tool energy efficiency monitoring system independently developed by Chongqing University is used to measure the real-time power of the machine tool, and the fixed power value of the machine tool measured during the cutting process is P 0 =1450w.

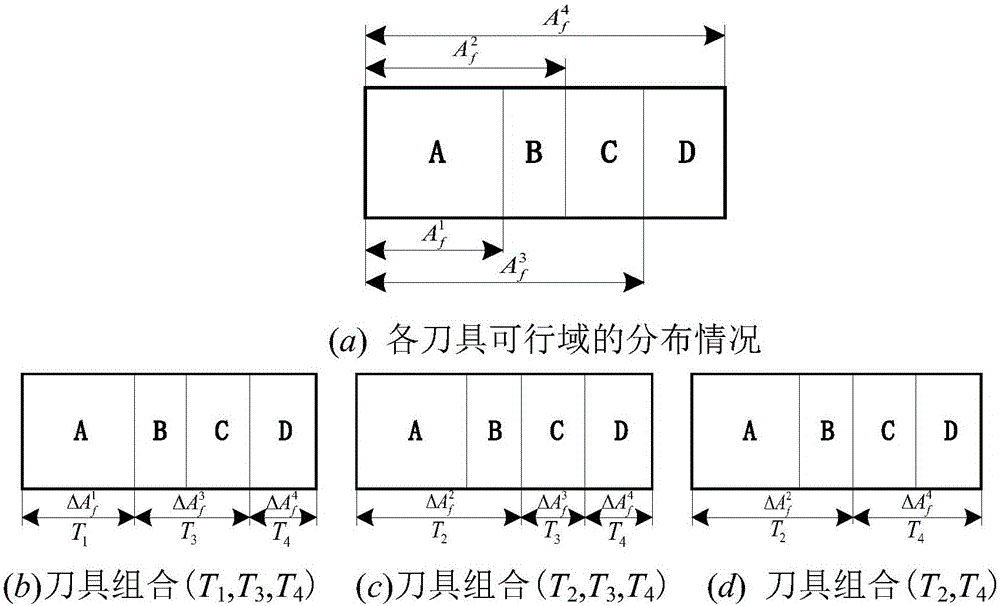

[0101] Tool combination o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com