Machining method for numerical control milling of thin-wall curved-surface irregular parts

A processing method and numerical control milling technology, applied in the field of mechanical processing, can solve the problems of difficult clamping and complex processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

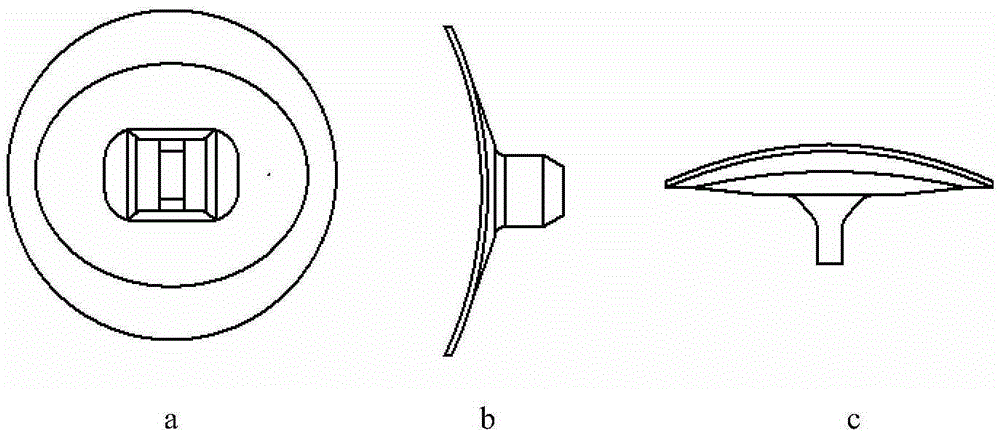

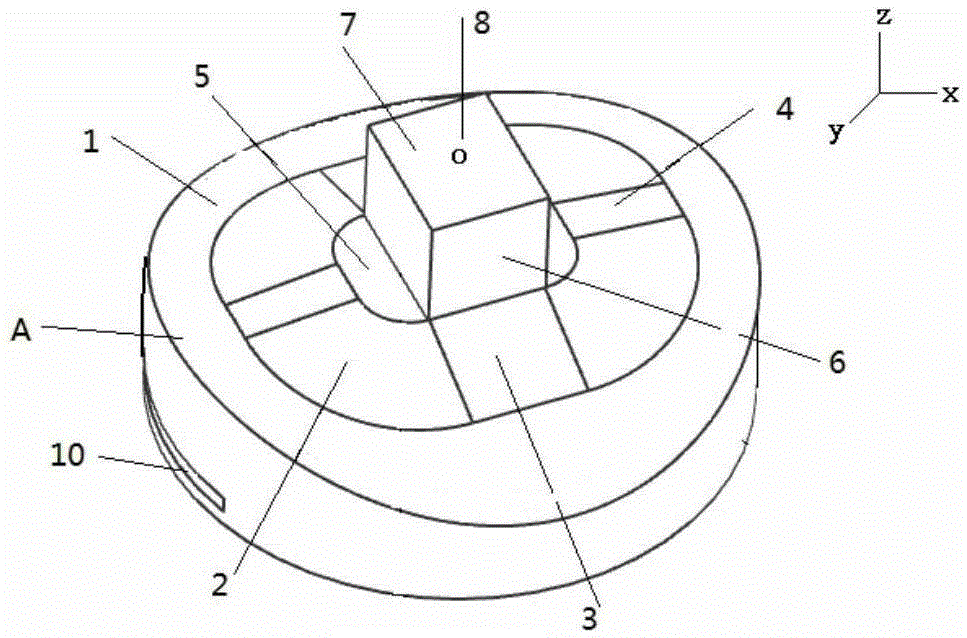

[0075] This embodiment is a method of milling the upper and lower profiles of a thin-walled curved surface special-shaped part using a three-axis milling machining center.

[0076] The thin-walled curved surface special-shaped parts are made of ultra-high-strength steel 30Si2MnCrMoVe. The blanking size is Ф330×138. After turning the end face and outer circle and flaw detection, a circular block-shaped blank with thin-walled curved surface is obtained. The upper profile, the lower profile and the workpiece lifting lug of the thin-walled curved surface special-shaped part are processed by numerical control milling according to the following steps.

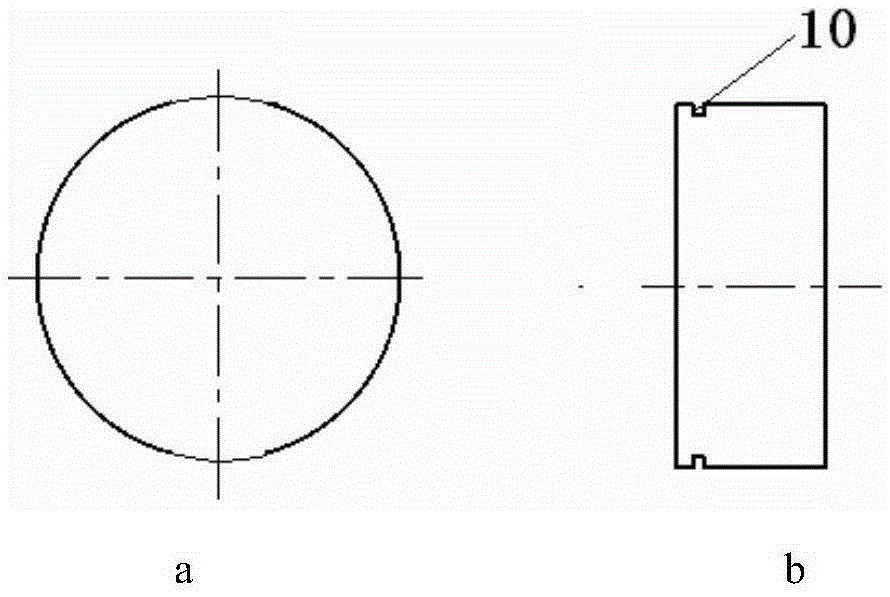

[0077] Step 1, process the milling process to press the groove. Horizontal process pressure grooves 10 are milled on both sides of the blank respectively, and are used for clamping and positioning of the workpiece during subsequent processing of the profile. The space between the centerline in the width direction of the process emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com