Punching machine mechanical arm device

A technology of manipulator and punching machine, applied in the field of punching machine manipulator device, can solve the problems of affecting observation, affecting the loading and unloading and maintenance of punching die, and achieves the effect of convenient loading, unloading and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

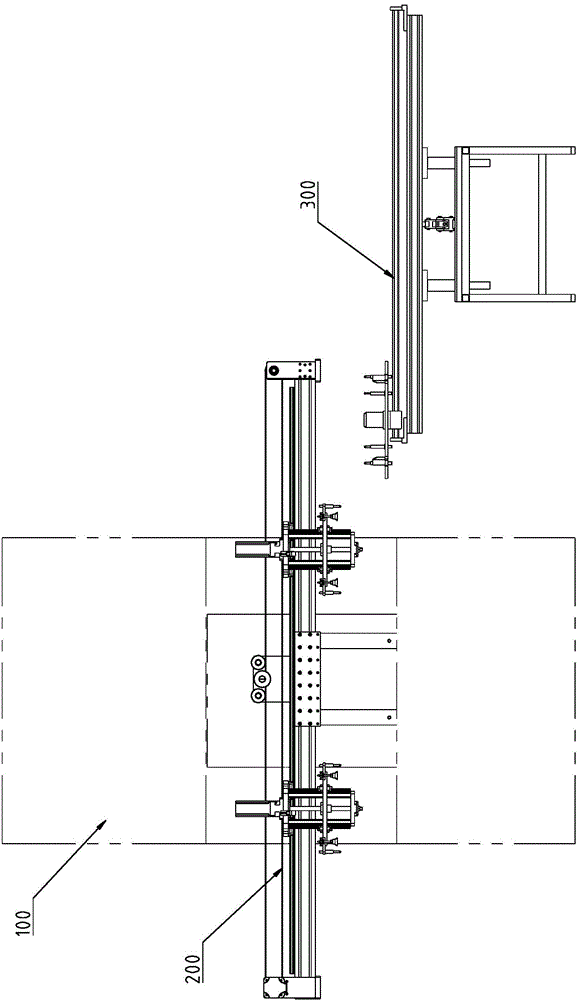

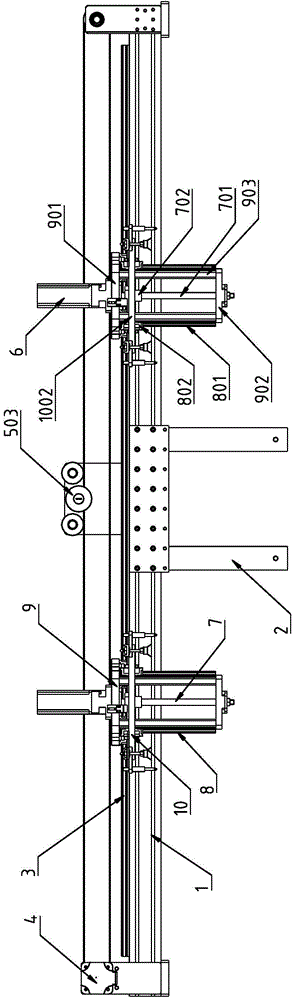

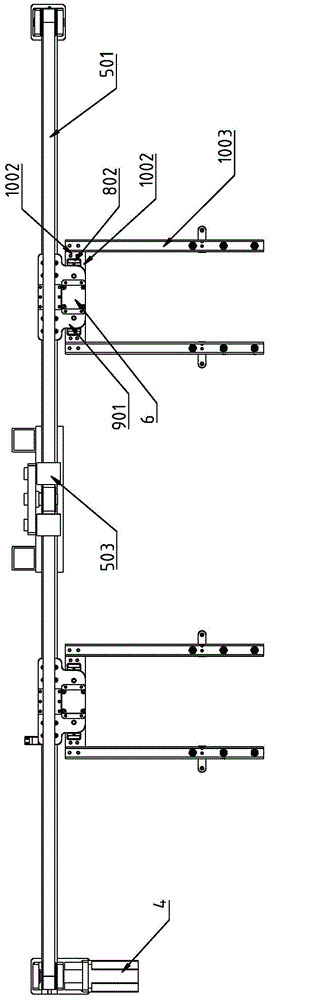

[0041] The punching machine manipulator device of the embodiment of the present invention is used to work with the punching machine, and is used for loading and unloading the disc-shaped workpiece. Its structure is as follows: Figure 1 to Figure 16 As shown, the punch manipulator device is installed on the workbench of the punch press 100, and a transfer table 300 is also equipped for unloading the workpiece and transferring it to the next process.

[0042] The punch manipulator device 200 includes a frame, two manipulators and a transverse drive mechanism.

[0043] The frame includes a beam 1 and a bracket 2 , the beam 1 is fixed on the bracket 2 , and the bracket 2 is fixed on the bed of the punch press 100 . The beam 1 is arranged behind the punch of the punch press 100 .

[0044] The transverse drive mechanism is installed on the beam 1. Manipulator comprises dolly 9, suction cup 10 and suction cup lifting mechanism.

[0045] The trolleys 9 of the two manipulators are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com