Mechanical hand for stamping and automatic loading and unloading

A technology of manipulators and presses, which is applied in the field of metal pressure processing, can solve problems such as harsh working environment, inability to meet multiple varieties, modern production methods of small and medium batches, and difficulty in product adjustment, and achieve the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

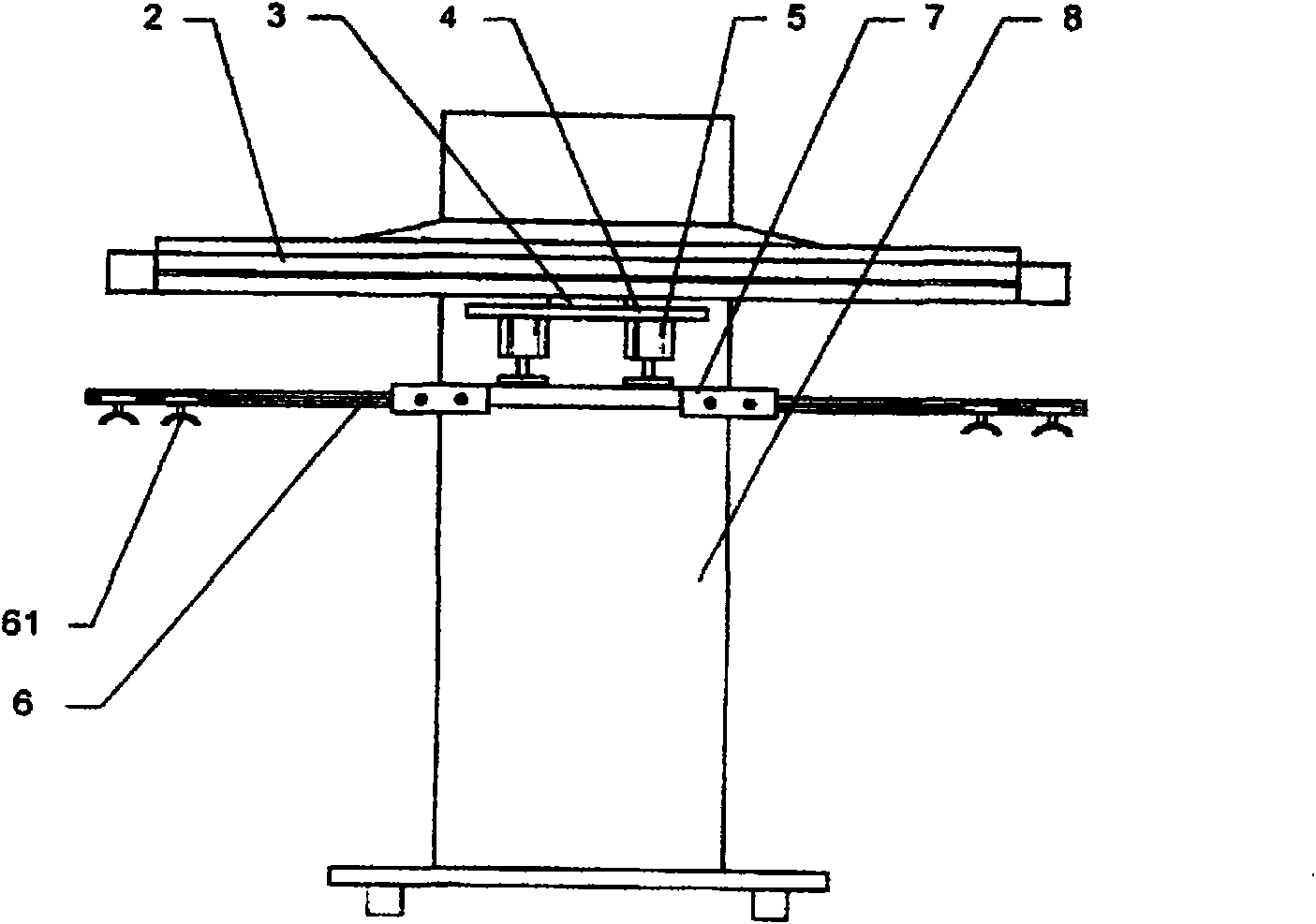

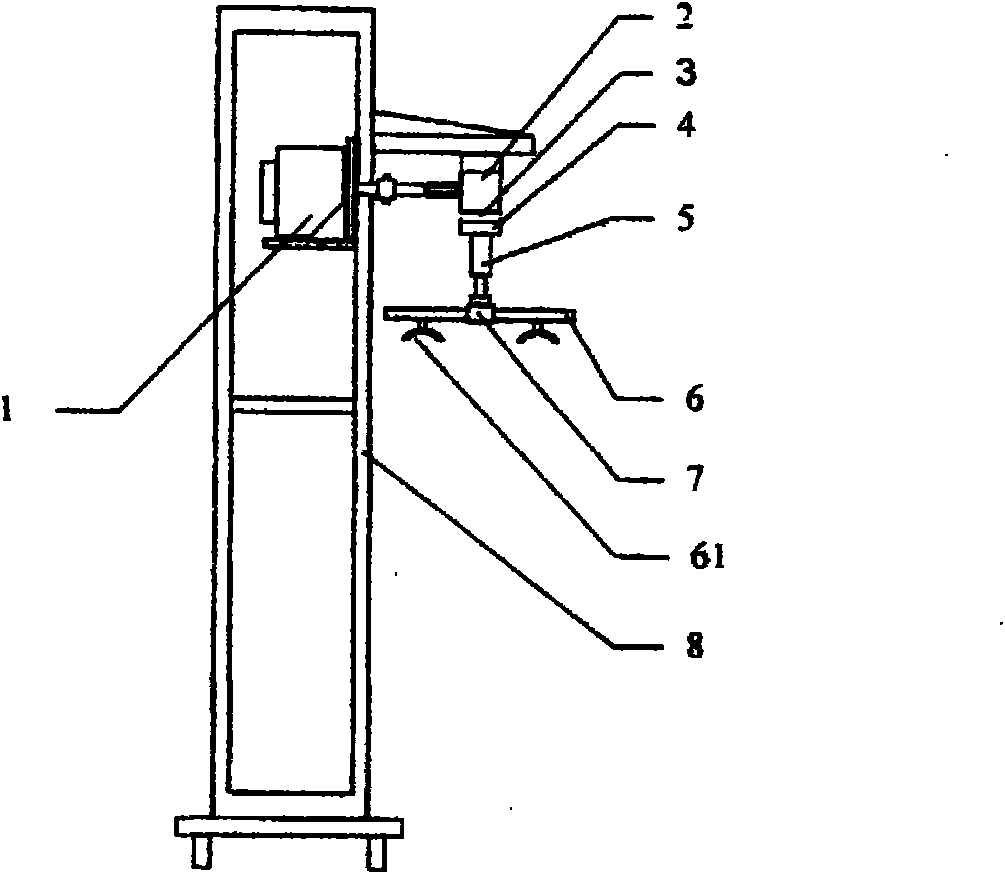

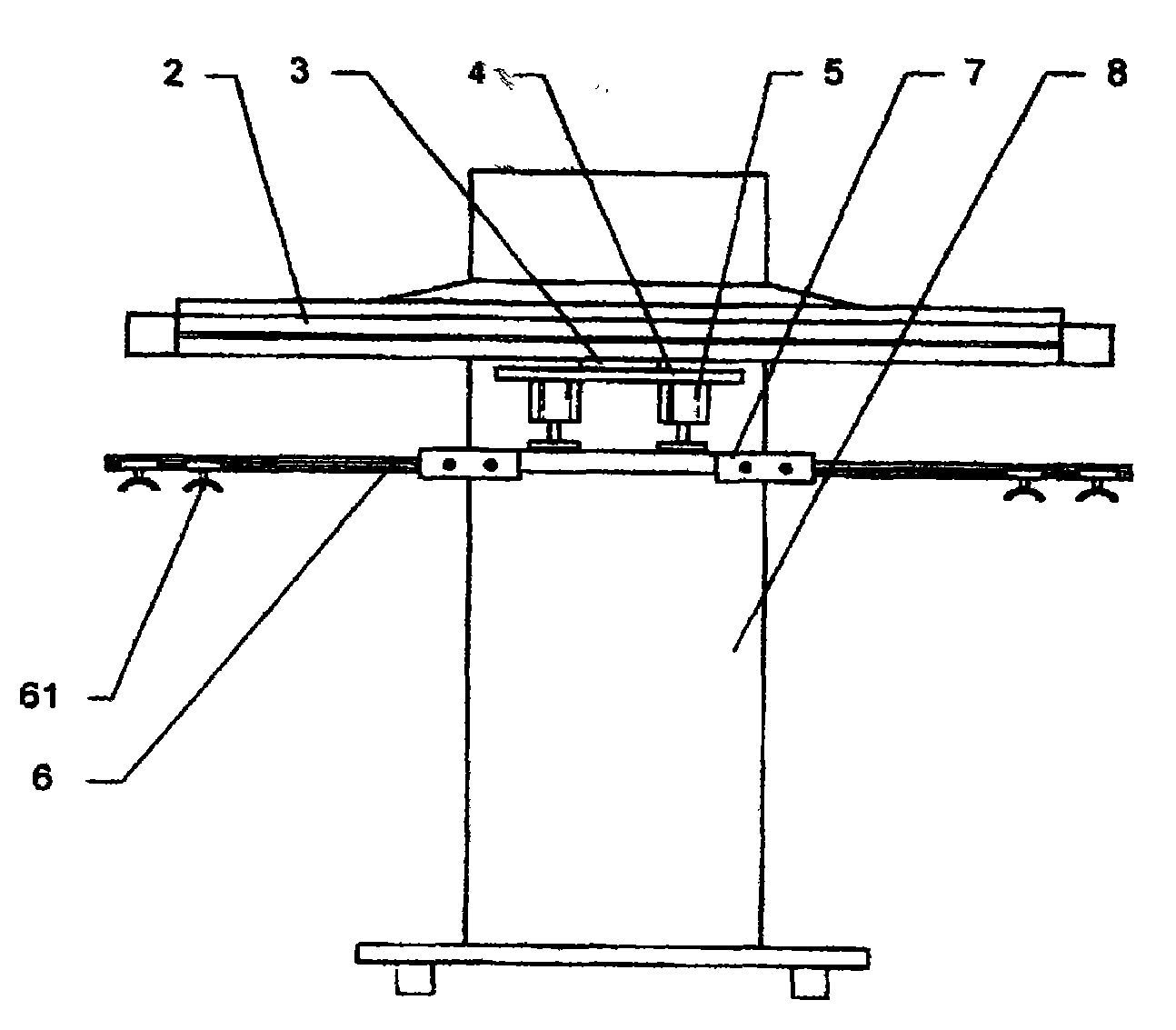

[0010] The structure and principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Such as figure 1 , 2 As shown, it is independently placed beside the press, including AC servo motor 1, linear guide rail 2, slider 3, cylinder 5, end picker 6, and frame 8, wherein the AC servo motor 1 controlled by the controller is installed on the frame 8, on one side of the frame 8, the AC servo motor 1 is meshed with the pulley of the linear guide rail 2 through a pulley of a synchronous belt, and the slider 3 is fixedly installed on the synchronous belt of the linear guide rail 2, and its sliding The bottom of the block 3 is fixedly connected with the cylinder 5 through the support plate 4, the support plate 7 is below the cylinder 5, and a detachable end picker 6 is provided on both sides of the support 7; the end picker 6 is provided with a mobile arm. The vacuum suction cup 61.

[0012] The controller connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com