Air-cooled intercooler

An air-cooled and cooler technology, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of large flow resistance of spoilers with variable tooth width, weak heat dissipation capacity of corrugated fins, etc., and achieve compact structure , long service life, and the effect of improving air intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

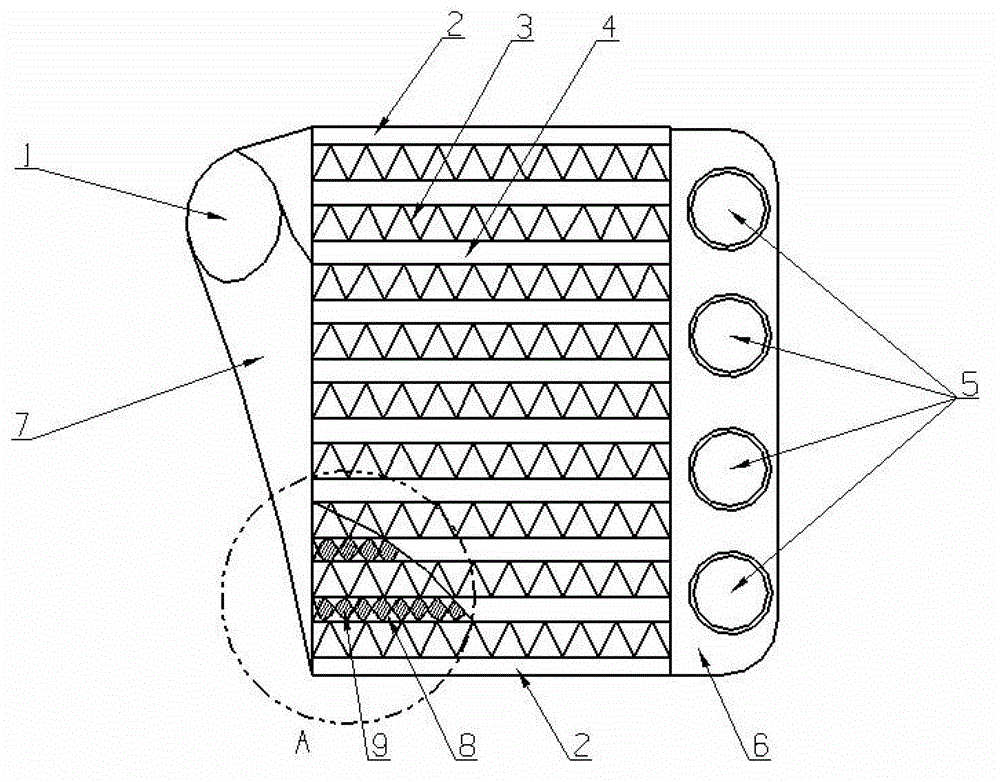

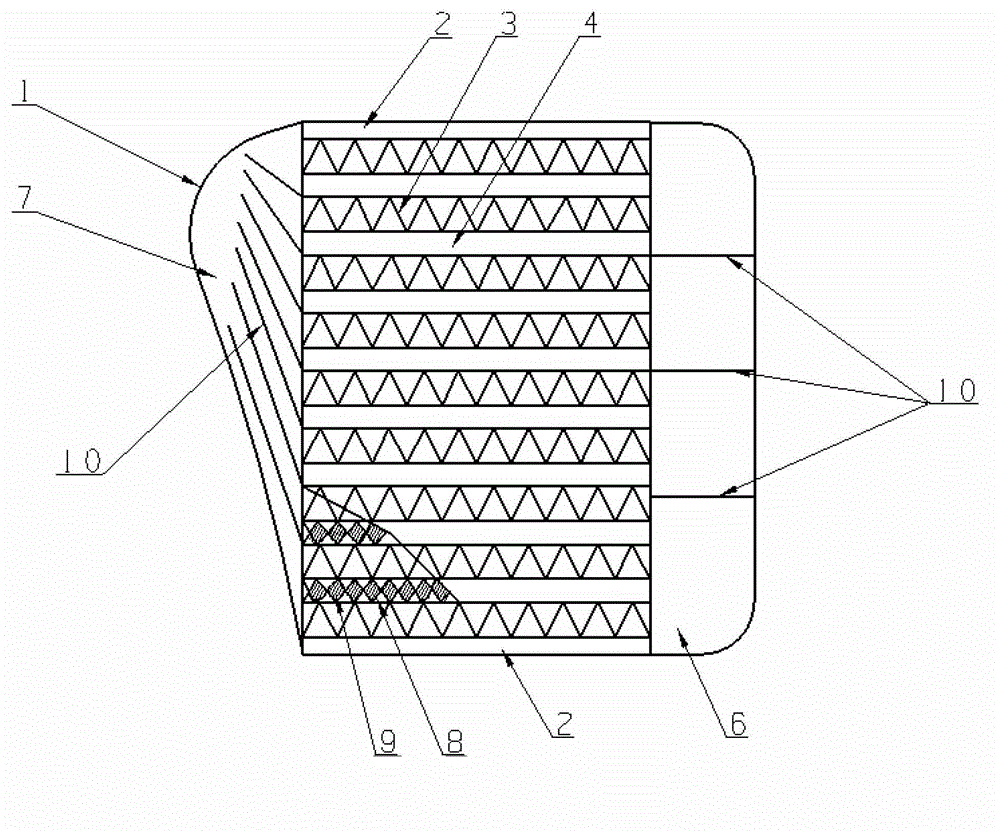

[0030] see Figure 1 ~ Figure 3 , The air-cooled intercooler of the present invention includes a core body and an air inlet 1 and an air outlet 5 connecting the core body. The core body is mainly composed of a side plate 2, an air intake chamber 7, an exhaust chamber 6, a heat dissipation pipe 4, and a heat dissipation fin 3, etc., wherein the side plate 2 includes two upper and lower pieces, which are combined to form a frame of the core body. The air intake chamber 7 and the exhaust chamber 6 are arranged at both ends of the frame, and the heat dissipation pipes 4 and the heat dissipation fins 3 are arranged in the frame.

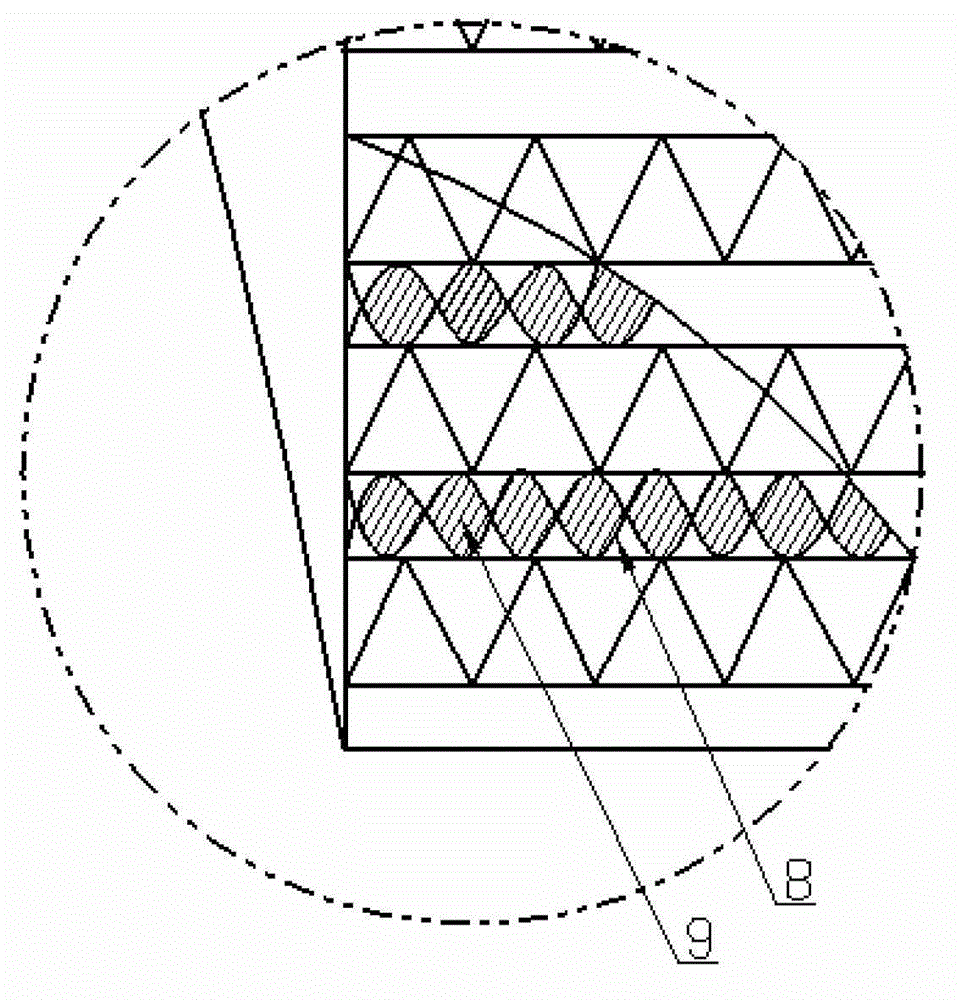

[0031] see Figure 1 to Figure 6, the radiating pipes 4 are eight, arranged at equal intervals from top to bottom between the upper and lower side plates 2, the two ends of each radiating pipe 4 communicate with the air intake chamber 7 and the exhaust chamber 6 respectively, and the radiating pipes 4 are Flat tube with a height of 7mm. Each heat pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com