Welded plate type heat exchanger

A technology of heat exchangers and welded plates, which is applied in the direction of indirect heat exchangers, heat exchanger types, fixed plate conduit components, etc., can solve problems such as poor fluidity and limited application range, and achieve reduced production costs and anti-oxidation Enhanced performance and enhanced corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

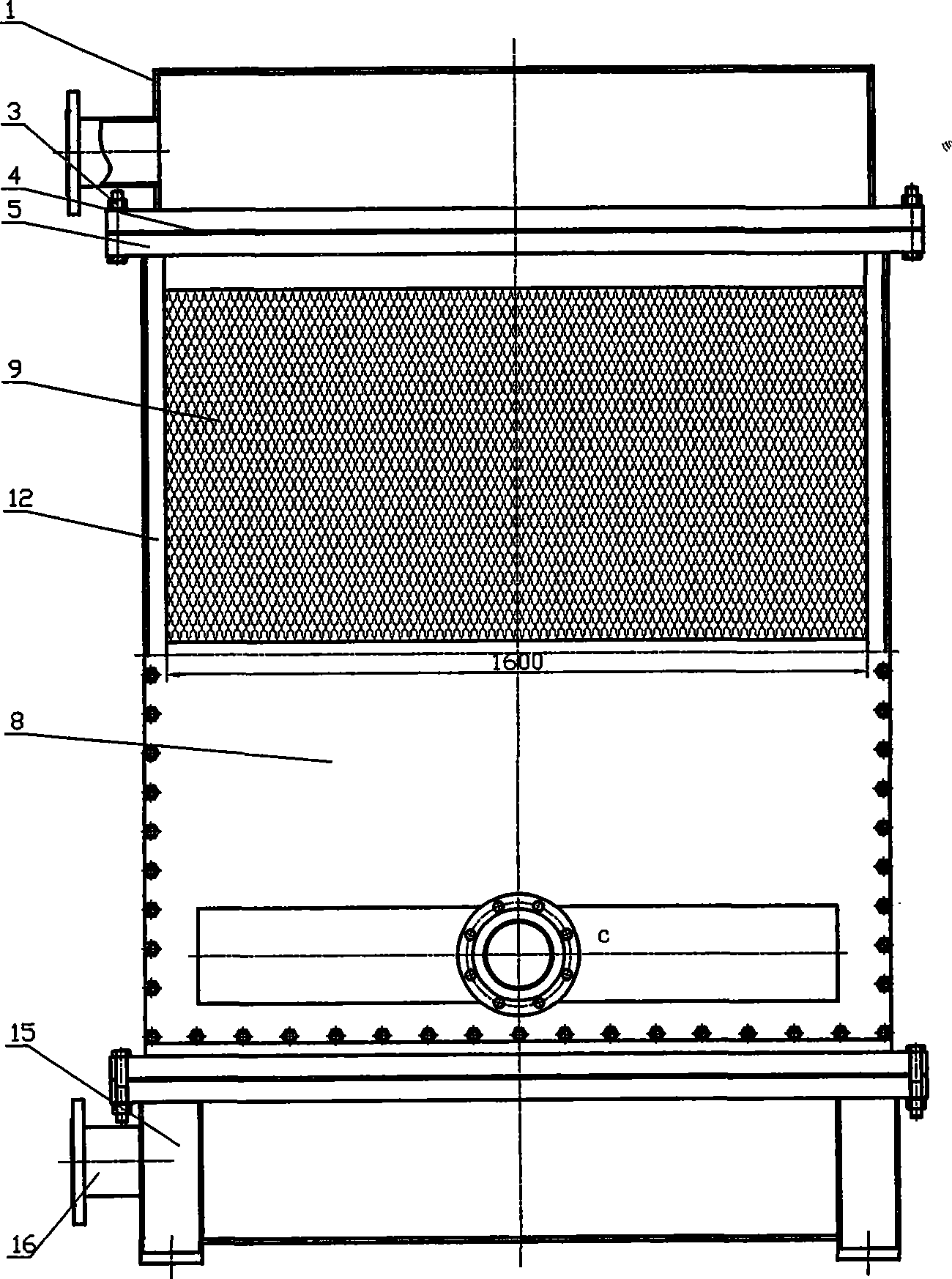

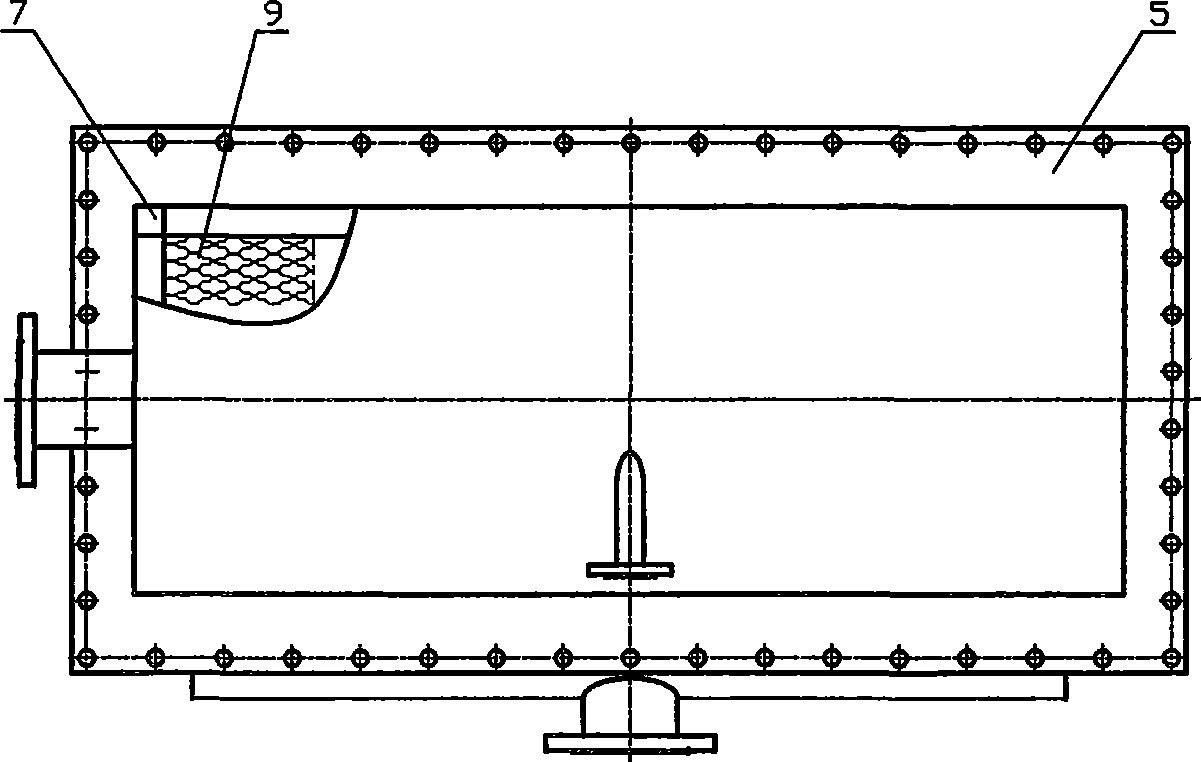

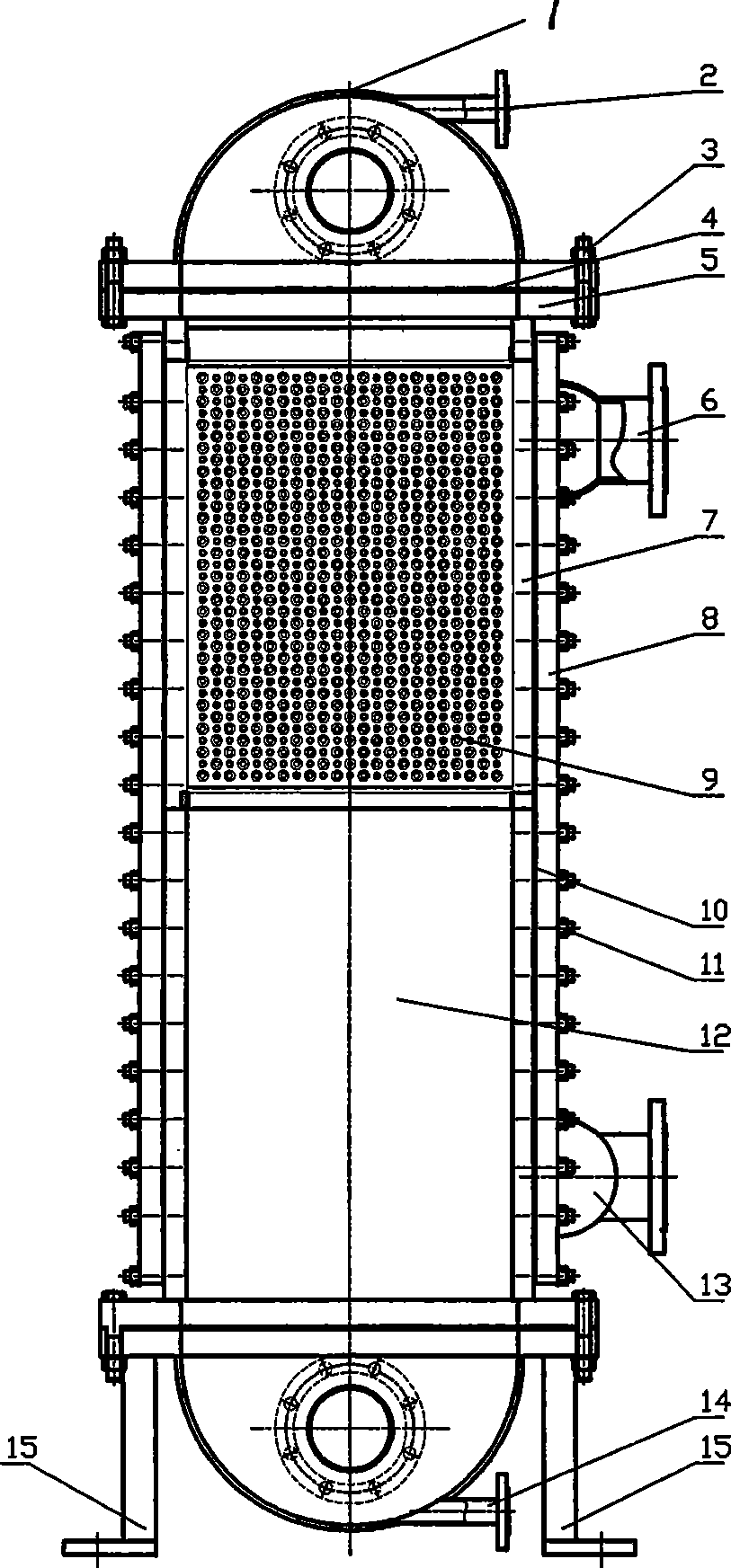

[0021] figure 1 , figure 2 , image 3 The main structure of the present invention is shown. This welded plate heat exchanger includes a frame 7, a foot 15 located at the bottom of the frame 7, and a head 1 is respectively arranged on the upper and lower parts of the frame 7, and a medium II is respectively arranged on the head 1. Inlet or outlet 16, exhaust port 2 or sewage outlet 14 are respectively provided on the head 1, a movable plate 8 and a fixed plate 12 are provided in the middle of the frame 7, and collection boxes 13 are respectively provided on the upper and lower parts of the movable plate 8, The medium I inlet or outlet 6 is respectively welded on the assembly box, and the head 1, the movable plate 8, and the fixed plate 12 are sealed and connected with the frame 7 through the connection flange 5, the sealing gasket 4, the sealing gasket 10, the bolt 3, and the bolt 11. A heat exchanger box is formed, and a heat exchange plate bundle 9 is arranged inside the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com