Particle dissolving and stirring part

A technology for stirring parts and particles, applied in the field of particle dissolving stirring parts, can solve the problems of prolonged stirring period, different dissolving speed, low stirring efficiency, etc., and achieve the effect of improving stirring efficiency and improving the effect of turbulence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

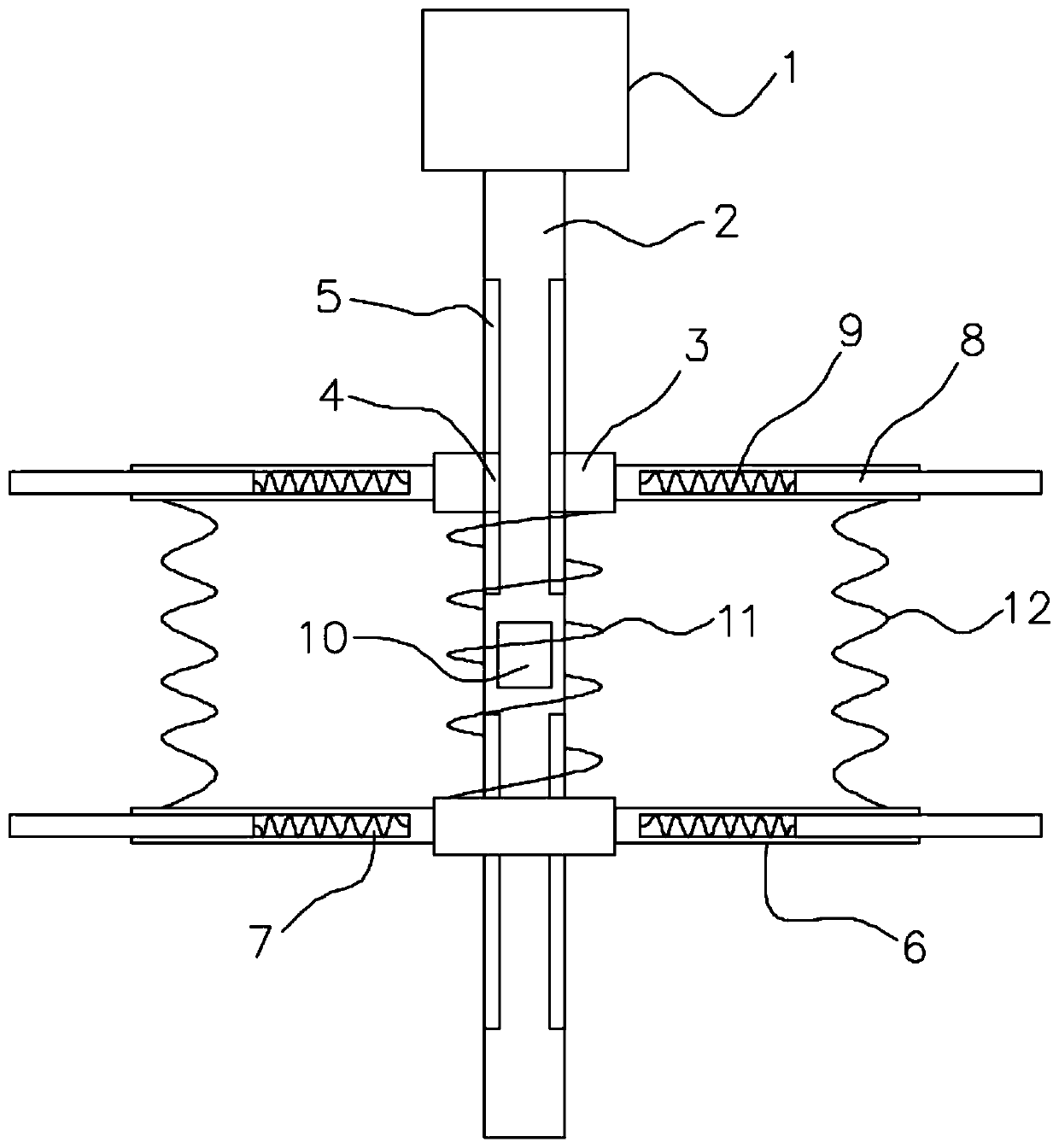

[0016] refer to figure 1 , a particle dissolving stirrer, comprising a variable frequency motor 1, the output end of the variable frequency motor 1 is fixedly connected with a stirring shaft 2, the stirring shaft 2 is embedded with an electromagnetic block 10, and the electromagnetic block 10 is connected to an external DC power supply through a rheostat, The direction of the magnetic field generated by the electromagnetic block 10 is fixed, and two permanent magnet rings 3 are sheathed symmetrically with respect to the electromagnetic block 10 on the stirring shaft 2, and the electromagnetic block 10 is arranged to repel each other with the two permanent magnet rings 3 respectively, and the two permanent magnet rings 3 The suction is set, the inside of the permanent magnet ring 3 is symmetrically provided with a limit mechanism, the stirring shaft 2 is sleeved with a second spring 11, and the two ends of the second spring 11 are fixedly connected with the two permanent magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com