Radiator

A technology of radiator and heat dissipation fins, applied in the direction of instruments, instrument cooling, electric solid devices, etc., can solve problems such as the reduction of heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further description will be made below in conjunction with the embodiments with reference to the accompanying drawings.

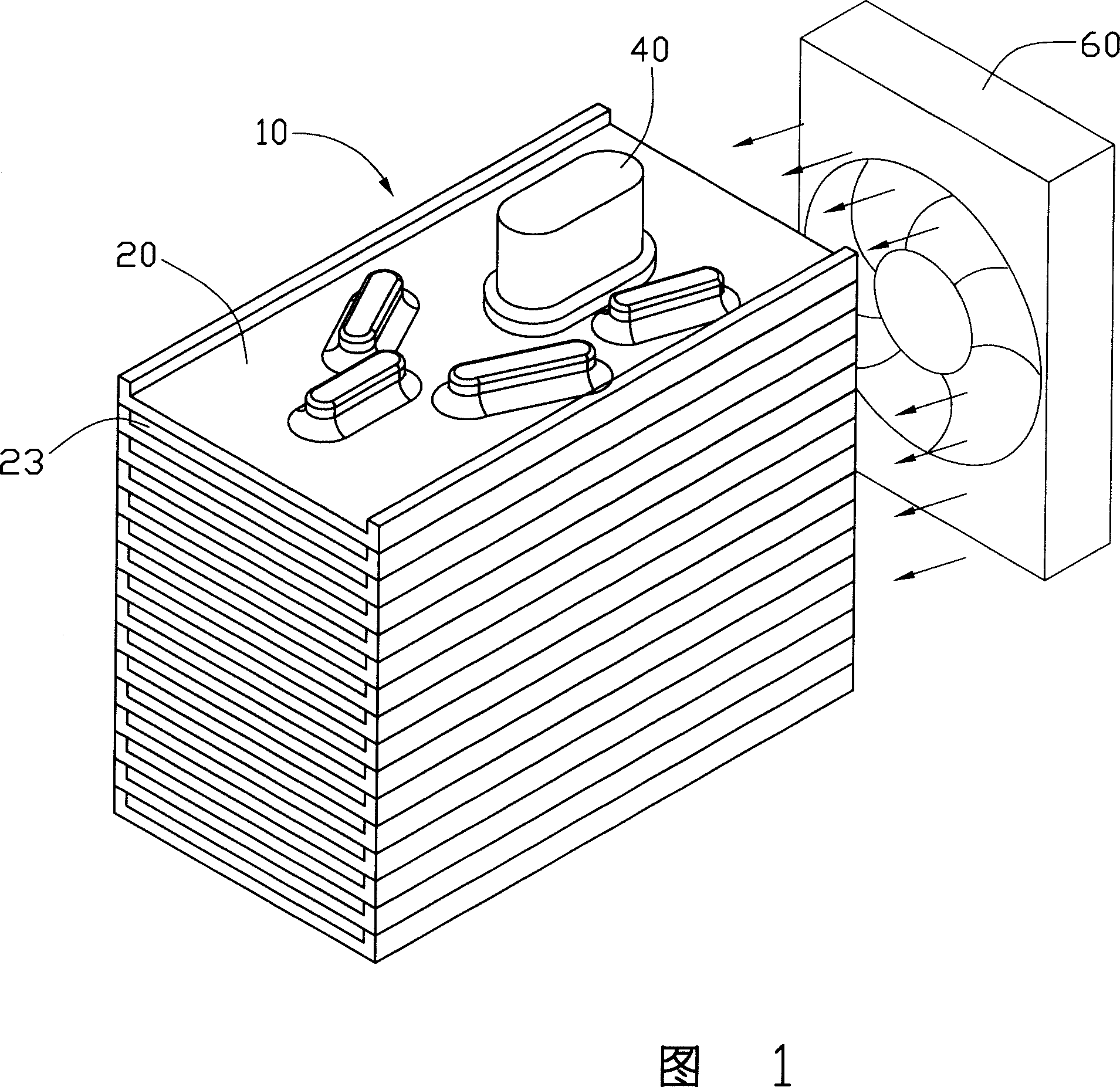

[0012] As shown in Figure 1, the radiator includes a heat dissipation fin set 10, a heat pipe 40 passing through the heat dissipation fin set 10, and a heat dissipation fan placed at one end of the heat dissipation fin set 10 for providing forced airflow 60. The airflow generated by the fan 60 can flow into the heat dissipation fin set 10 along the direction indicated by the arrow in the figure, so as to exchange heat with the heat dissipation fin set 10 to remove heat.

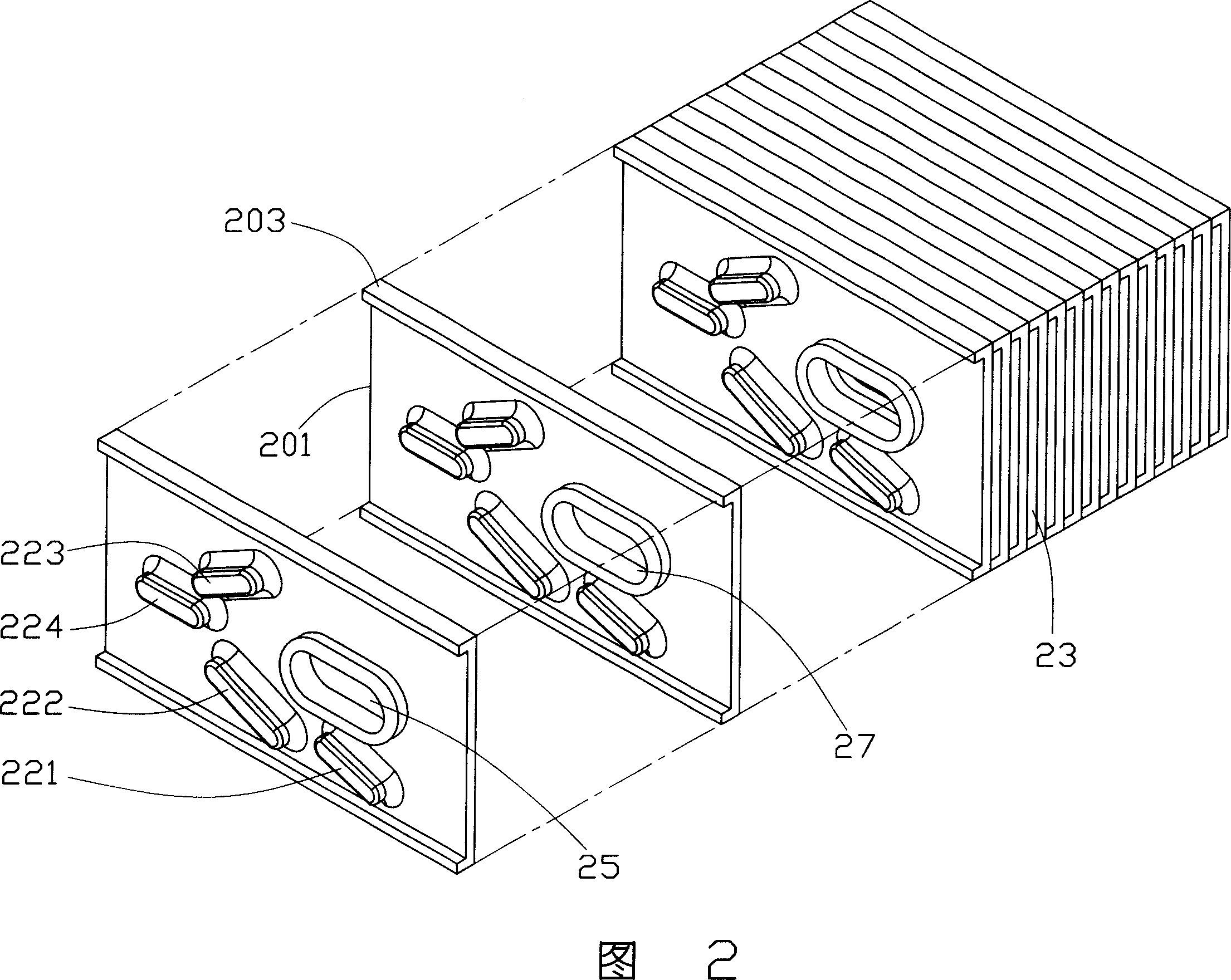

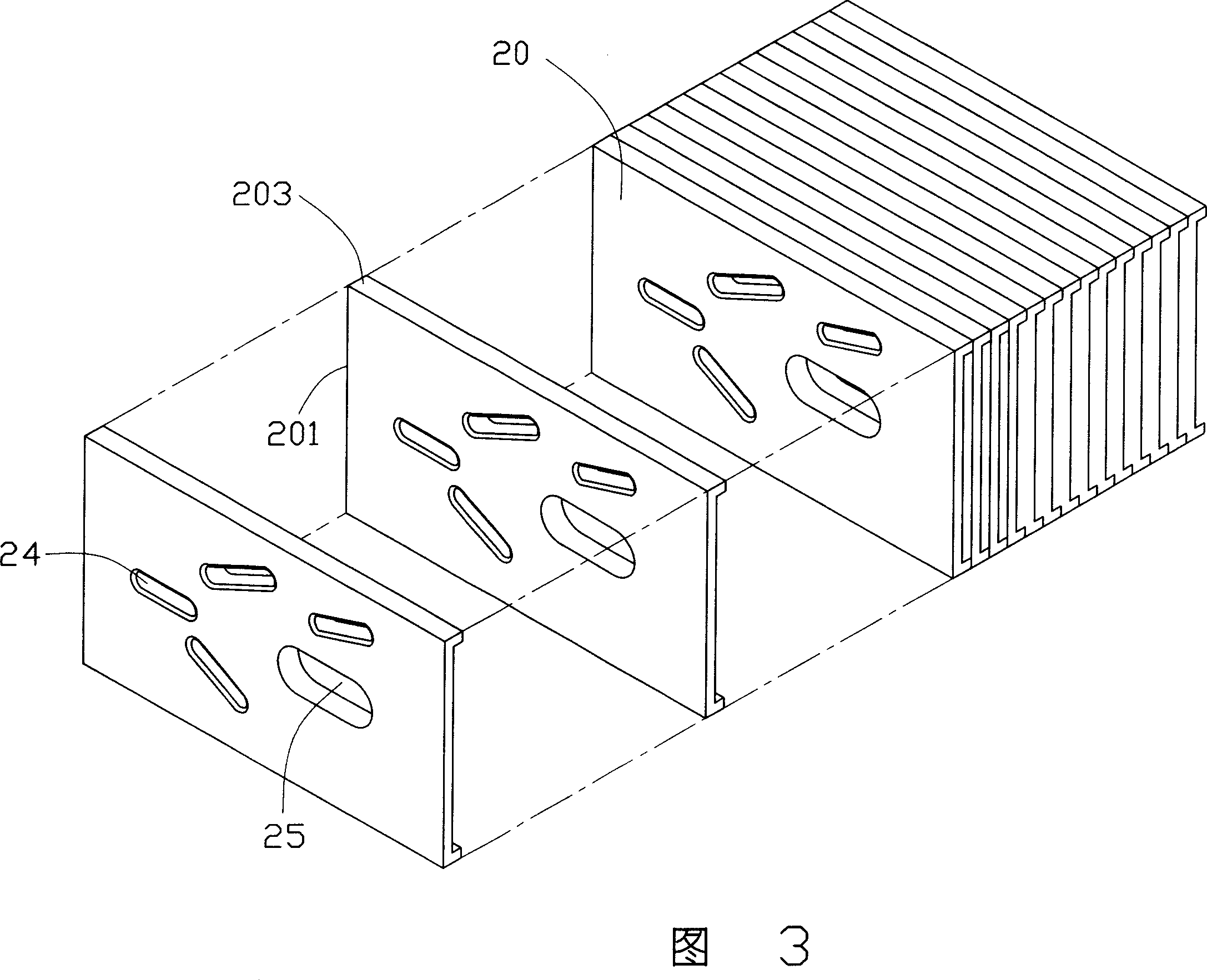

[0013] Please refer to FIGS. 2 to 4 at the same time. The heat dissipation fin group 10 includes a number of fins 20 arranged parallel to each other. Each fin 20 includes a body 201 and flanges 203 formed at both ends of the body 201. The folded edges 203 of the fins abut against each other, thereby forming a flow channel 23 extending along the length direction of the folded edges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com