Spiral arc-shaped heat exchange pipe and machining processes thereof

A processing technology and heat exchange tube technology, applied in the field of metal tube processing, can solve problems such as insufficient heat exchange, and achieve the effects of obvious turbulence effect, easy cleaning and less fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

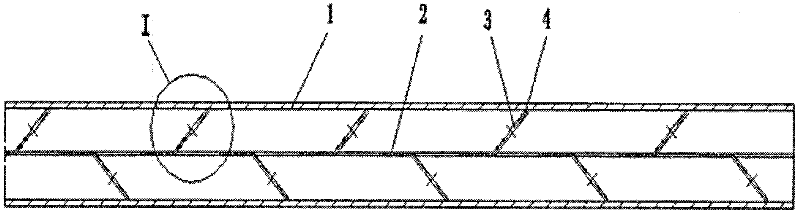

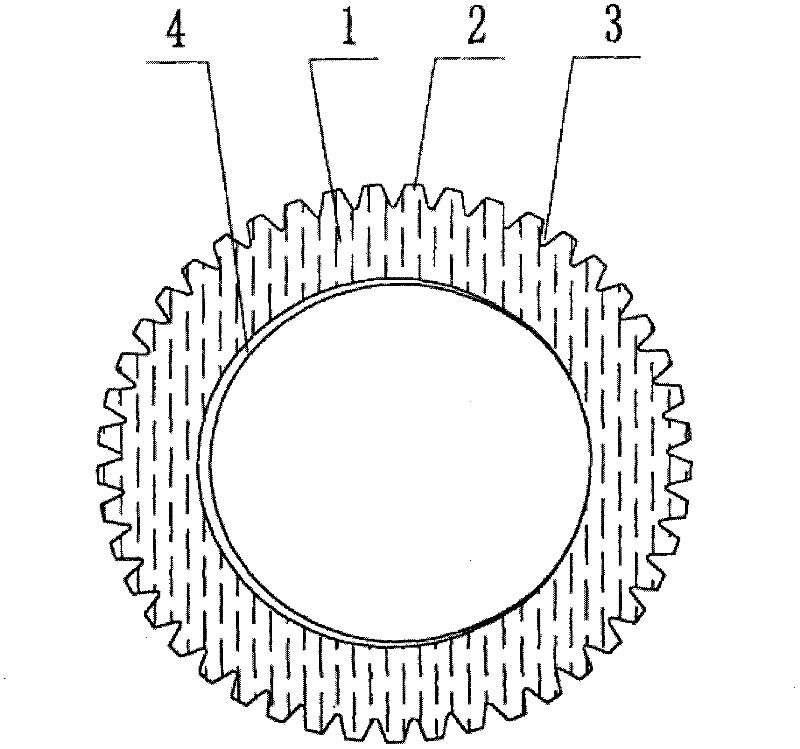

[0045] Such as Figure 4 , Figure 5 As shown, the arc-shaped heat exchange tube of the present invention has a main body of a metal tube body 1, especially, a metal welded tube in this embodiment. The pipe body 1 encloses and forms a medium channel 2 through which the heat exchange medium circulates, so as to realize the heat exchange of the medium inside and outside the pipe body 1 .

[0046] In this embodiment, the pipe body 1 as a whole is a special-shaped pipe section. Three arc-shaped grooves 31 are formed on the pipe wall of the special-shaped pipe section, and the three grooves 31 are parallel to each other and form a rotation angle with the axis of the pipe body 1 .

[0047] The three grooves 31 are correspondingly formed on the inner wall of the tube body 1 with three raised arc-shaped lines 32 .

[0048] In this embodiment, there are three grooves 31 arranged side by side. In other different embodiments, there may be one, two or more grooves.

[0049] In this emb...

Embodiment 2

[0054] Such as Image 6 As shown, another arc-shaped heat exchange tube of the present invention has basically the same structure as that of Embodiment 1, the difference is that the tube body 1 of the arc-shaped heat exchange tube also includes first straight pipe sections located at both ends 11 and the second straight pipe section 12.

[0055] In this embodiment, the lengths of the first straight pipe section 11 and the second straight pipe section 12 are unequal. Its beneficial effect is that when the arc-shaped heat exchange tube of the present invention is used for assembling heat exchange equipment, due to the limited space between the tube sheets, straight tube sections with unequal lengths at both ends are used, and the size can be borrowed from one end during assembly. , to make full use of the space between the tube sheets and improve the convenience of heat exchange equipment installation.

[0056] Of course, under normal circumstances, the first straight pipe sec...

Embodiment 3

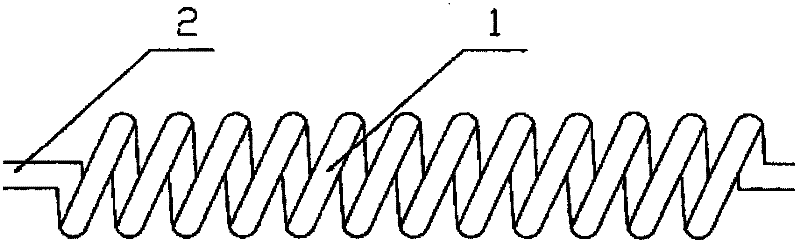

[0060] The present invention also provides a processing technology for the above-mentioned arc-shaped heat exchange tube, which includes the following steps: Step 1, obtaining a metal round tube, specifically, a metal welded tube in this embodiment. Step 2, put the metal round tube into the roller machine, keep the metal round tube still, and process and form one or more arc-shaped extending grooves on the tube wall of the metal round tube by turning the mold while moving the mold, so as to Correspondingly arc-shaped lines are formed on the inner wall of the tube.

[0061] As an improvement or optimization of the above-mentioned processing technology, the following processing steps can also be added:

[0062] Flatten the middle section of the metal round tube obtained in step 2, so that the middle part of the arc-shaped heat exchange tube is oval, and then bend the oval metal round tube into a U-shape or an S-shape. A first straight pipe section and a second straight pipe sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com