Device for desorbing sulfur trioxide in the front of air preheater

A technology of sulfur trioxide and air preheater, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, separation methods, etc., and can solve unfavorable reactions between absorbents and sulfur trioxide, no use of enhanced mixing devices, blockage of air preheaters, etc. problems, achieve the effect of shortening the length of the reaction zone, ensuring the uniformity of mixing, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

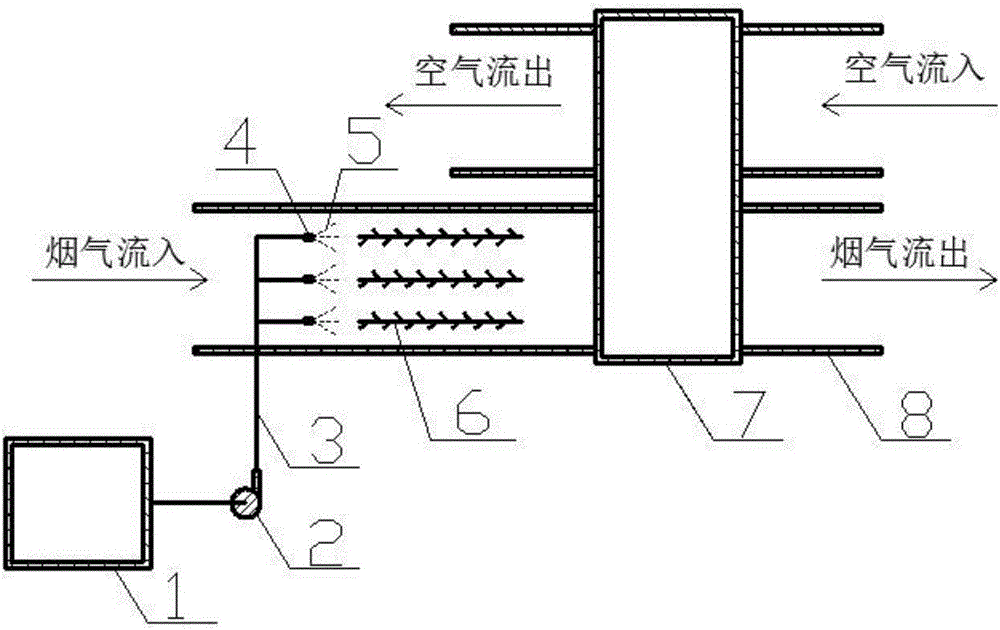

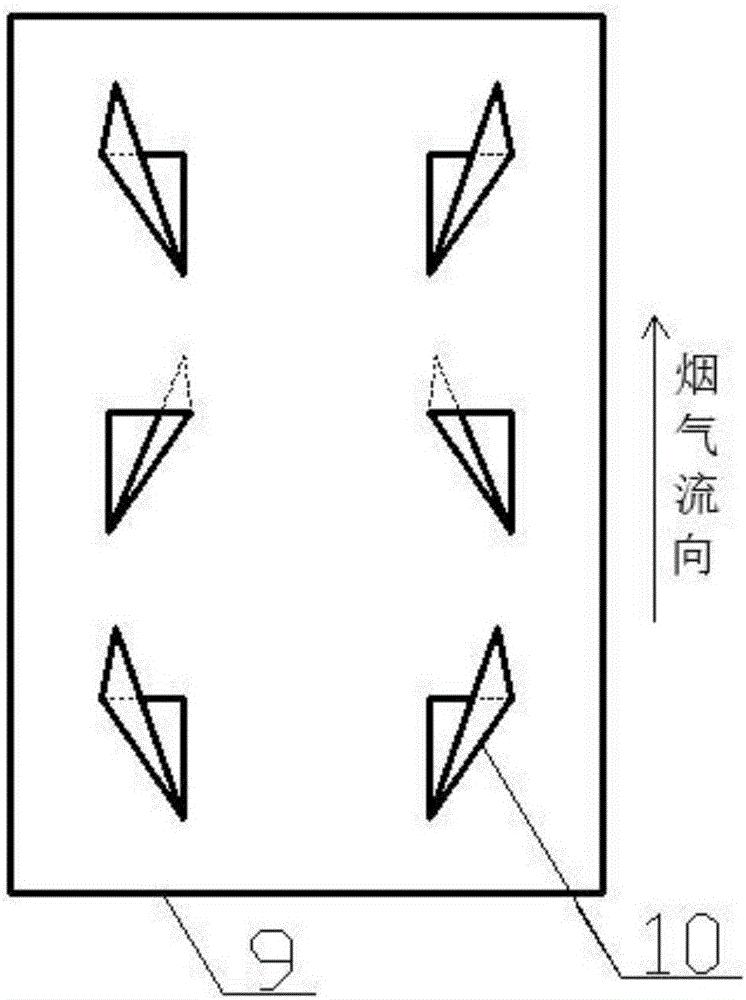

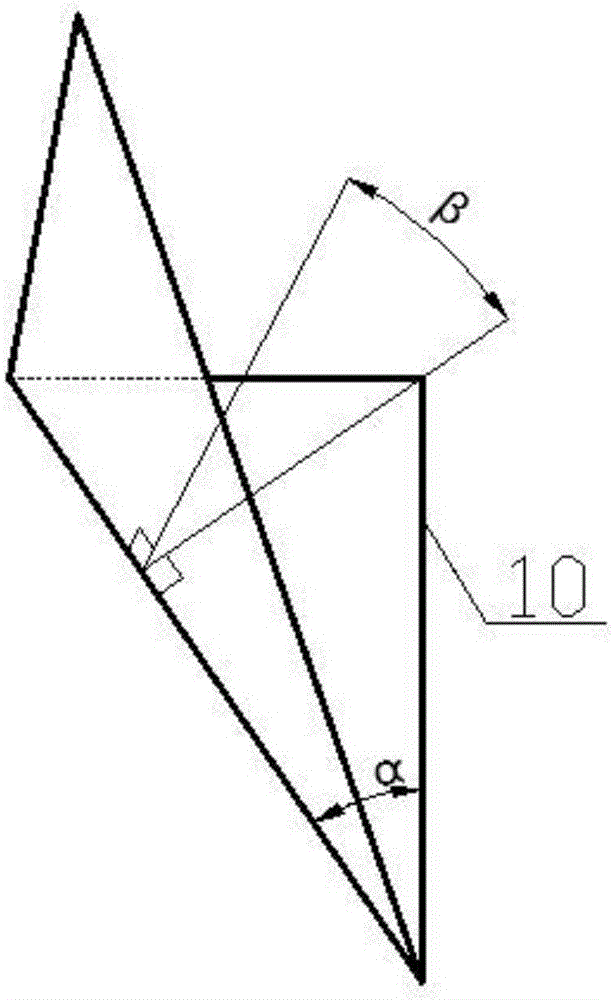

[0023] The present invention is a device for removing sulfur trioxide before the air preheater, such as figure 1 As shown, it includes a lye pool 1 for storing lye absorbent 5; a pump 2 with a liquid inlet and a liquid outlet, wherein the liquid inlet is connected to the lye pool 1, and the lye can be controlled by adjusting the pump power The flow rate of the absorbent 5; the atomizing nozzle 4 is used to spray the lye absorbent 5 into the flue 8; the lye delivery pipe 3 is connected to the pump 2 and the atomizing nozzle 4; the flue gas mixing unit 6 is used to strengthen the lye The mixing effect of the absorbent 5 and the flue gas, the flue gas mixing unit 6 is composed of a base plate 9 and fins 10, wherein the fins 10 are obtained by cutting the base plate 9 and then bending or welding....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com