Semi-open-type rotor

A semi-open rotor technology, applied in the direction of rotating equipment cleaning, cleaning heat transfer devices, damage protection, etc., can solve the problems of reduced life of the shaft, damage to the inner wall of the heat exchange tube, and large driving torque, so as to save material costs and strengthen the exchange rate. Thermal effects, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

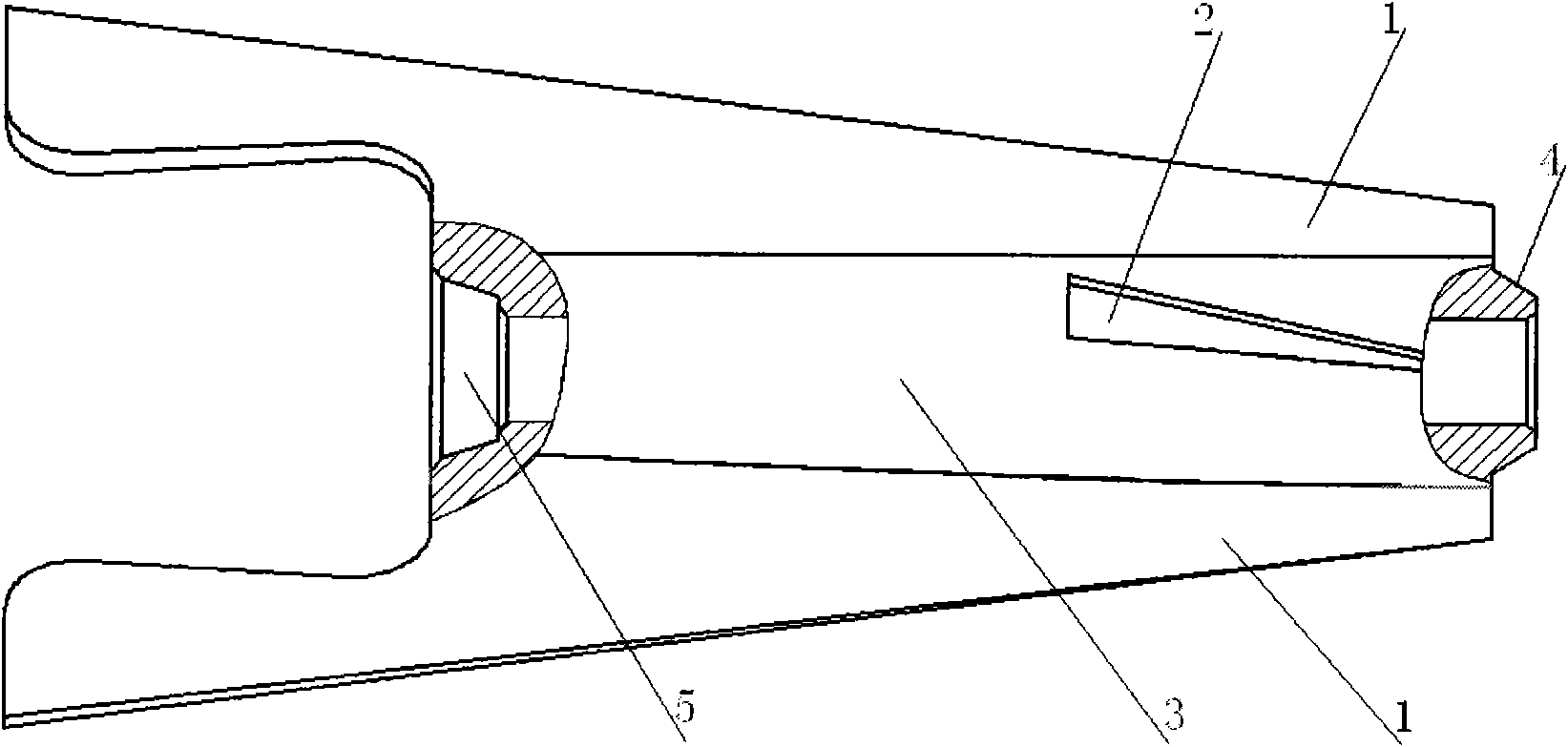

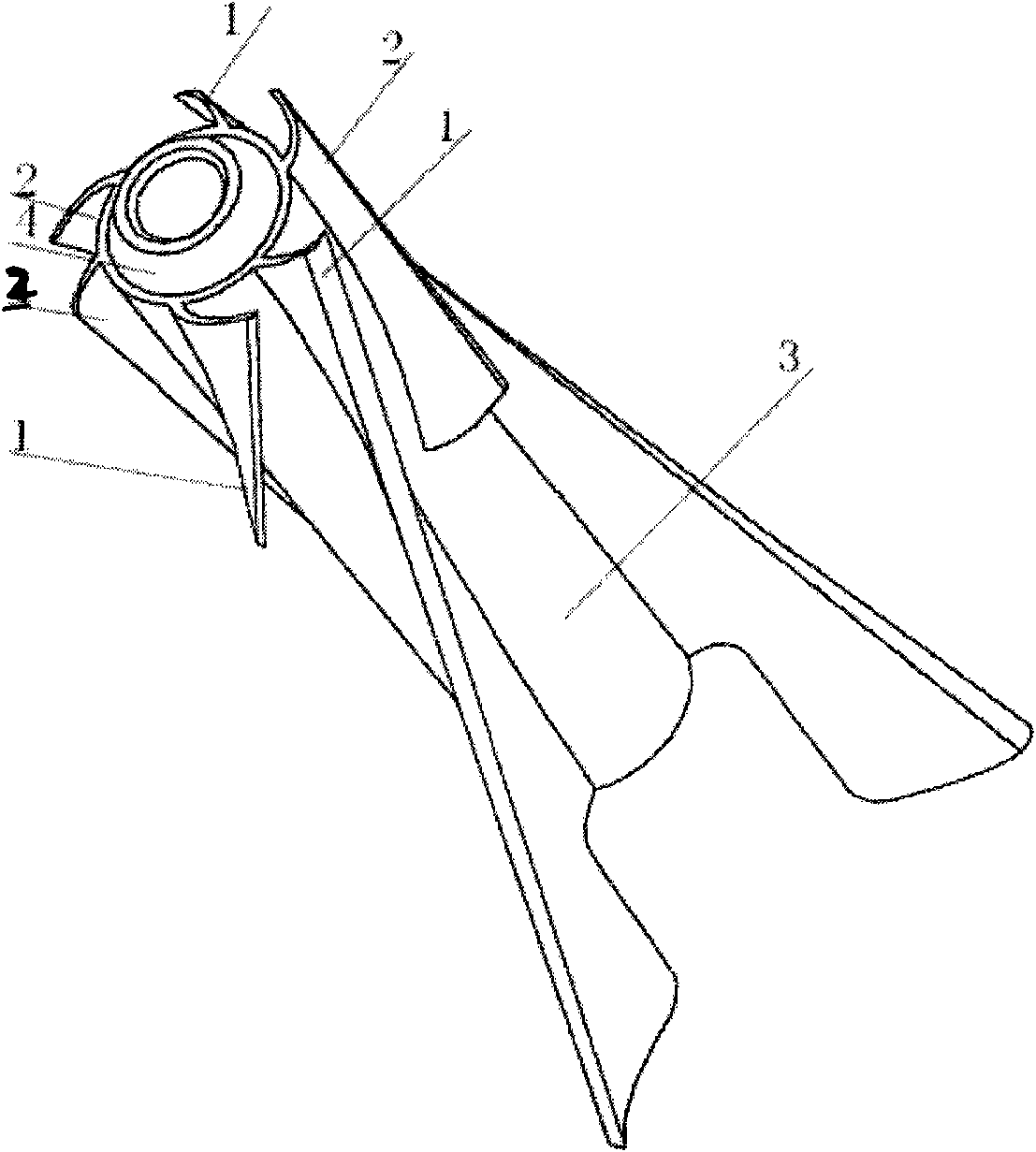

[0020] Such as Figure 7 As shown, the present invention relates to an implementation example of a semi-open rotor. A semi-open rotor of the present invention, a pendant 9 and a rotating shaft 10 are installed in the heat exchange tube 8. Several of the rotors are mounted on two On the rotating shaft 10 between the hanging parts 9, the hanging parts 9 are fixed on both ends of the heat exchange tube 8, and the two ends of the rotating shaft 10 are respectively fixed on the hanging parts 9. On the shaft 3, the radial width of the main blade 1 changes in the axial direction, and the main blade 1 at the rear part of the rotor is provided with a suspended part 6, which can cooperate with the front end of the adjacent rotor.

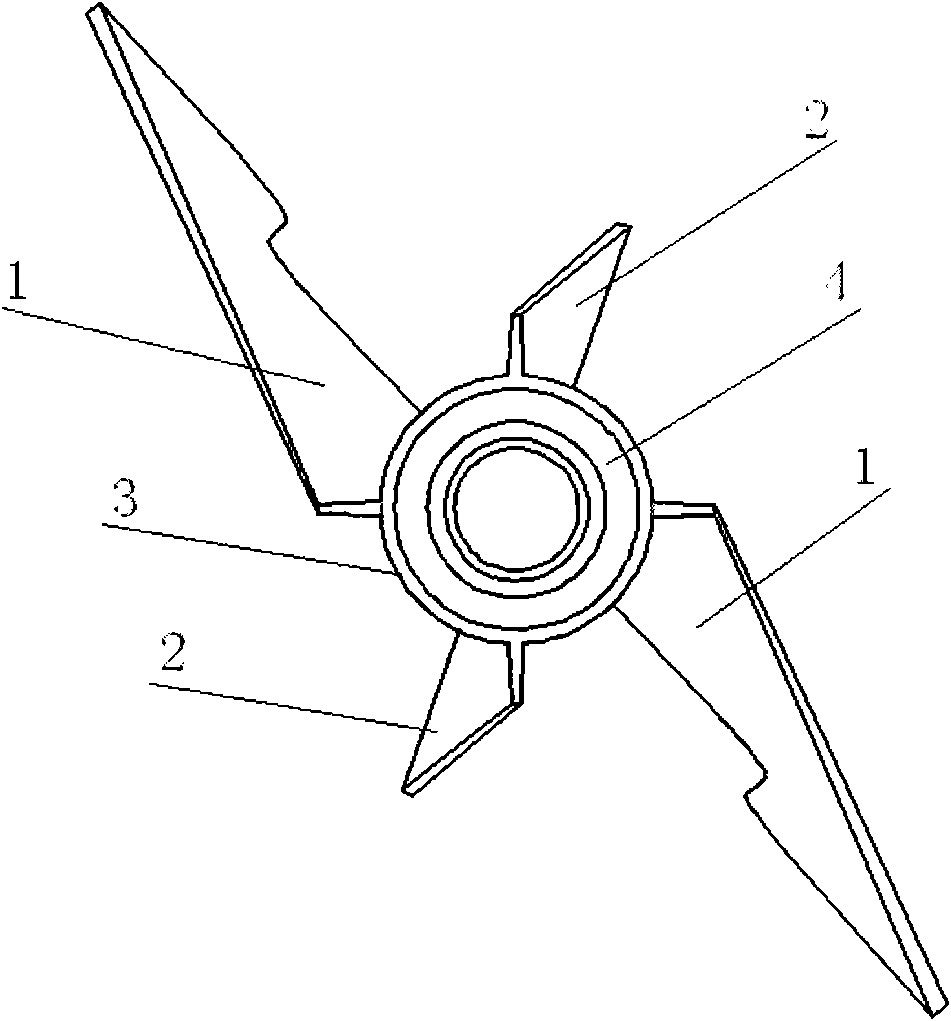

[0021] Figure 1 to Figure 6 As shown, the cross-sectional shape of the hollow shaft 3 of the rotor of the present invention is a hollow cylinder; figure 1 and figure 2 Among them, two main blades 1 and two auxiliary blades 2 are arranged on the rotor hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com