Polyimide foam, and preparation method and application thereof

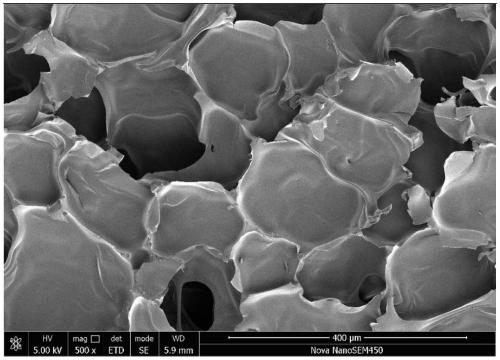

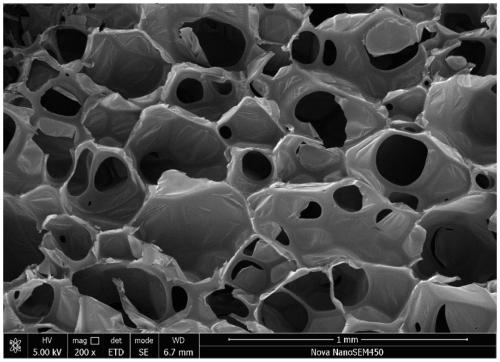

A technology of polyimide and bismaleimide, which is applied in the field of polymer materials, can solve the problems of foam heat resistance damage, low preparation efficiency, unfavorable industrial production, etc., achieve uniform cells, improve mechanical properties, Conducive to the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] According to a first aspect of the present invention, a kind of preparation method of polyimide foam is provided, comprising the following steps:

[0045] (A) providing the glue solution containing polyester ammonium salt oligomer, mixing the glue solution containing polyester ammonium salt oligomer with aromatic bismaleimide, and obtaining the foaming precursor after removing the solvent;

[0046] (B) Foaming the foaming precursor obtained in step (A), and then heat-treating to obtain a polyimide foam.

[0047] The source of the glue containing the polyester ammonium salt oligomer is not limited, and it can be prepared by a method commonly used by those skilled in the art. For example, the aromatic dianhydride is added into the mixed solvent of alcohol and ether, the aromatic dianhydride and the alcohol undergo esterification reaction, and then the aromatic diamine is added to obtain a glue solution containing polyester ammonium salt oligomer.

[0048] The types of ar...

Embodiment 1

[0083] A preparation method of polyimide foam, comprising the following steps:

[0084] (1) Provide glue containing polyester ammonium salt oligomer

[0085] Add 32.22g of 3,3',4,4'-benzophenonetetracarboxylic dianhydride (0.1mol) into a mixed solvent of 15g of methanol and 30g of tetrahydrofuran, under nitrogen protection, heat up to 60°C and reflux for 150min to obtain clarification After reducing the solution temperature to 30° C., 19.83 g of diaminodiphenylmethane (0.1 mol) was added, and the reaction was continued for 30 minutes to obtain a glue solution containing polyester ammonium salt oligomers.

[0086] (2) Preparation of foaming precursor

[0087] Add 5.7g of 4,4'-methylenebis(N-phenylmaleimide) to the glue containing polyester ammonium salt oligomer obtained in step (1), and continue to stir vigorously for 30min to obtain A homogeneous light brown transparent solution; the solution is concentrated and the foaming precursor is obtained after removing the solvent. ...

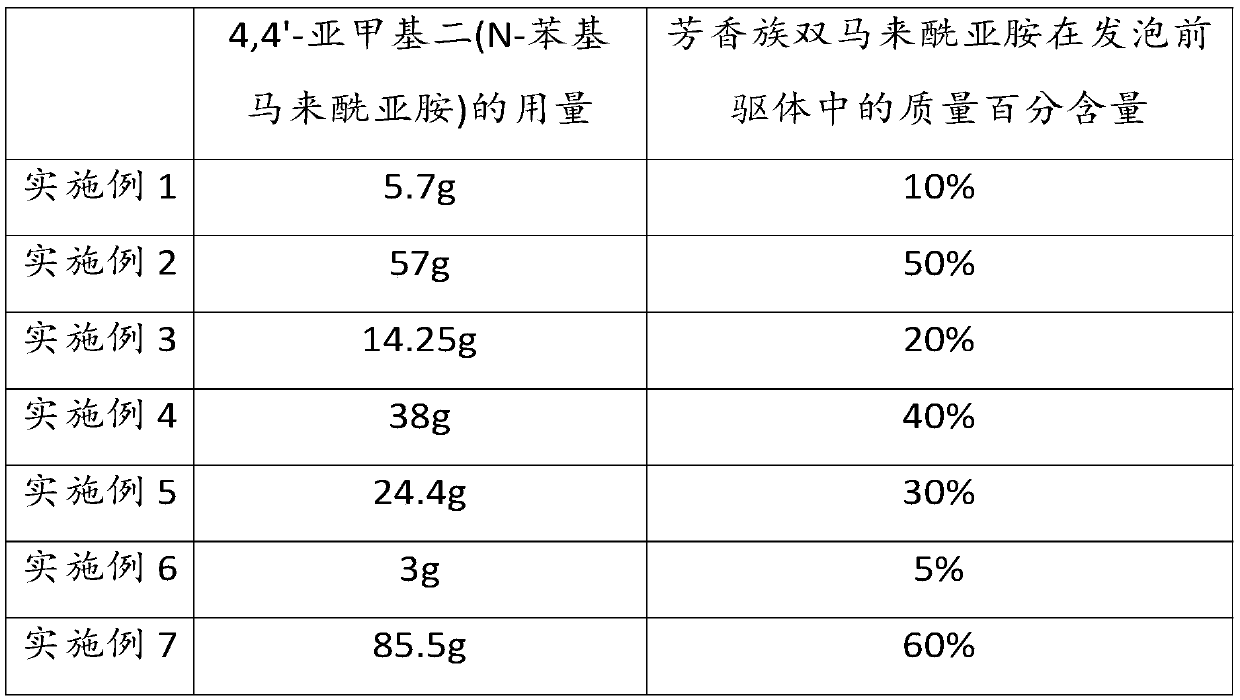

Embodiment 2-7

[0091] The difference between Examples 2-7 and Example 1 is that the amount of 4,4'-methylenebis(N-phenylmaleimide) in step (2) is different, as shown in Table 1 .

[0092] Table 1

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com