Natural graphite/copper composite heat sink and fabrication method thereof

A composite heat sink and natural graphite technology, which is applied in the field of natural graphite/copper composite heat sink and its preparation, can solve the problems of low mass production of artificial graphite, increase the heating value of equipment, and reduce the temperature of heating components, etc. Excellent electromagnetic shielding effect, improved thermal conductivity, excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

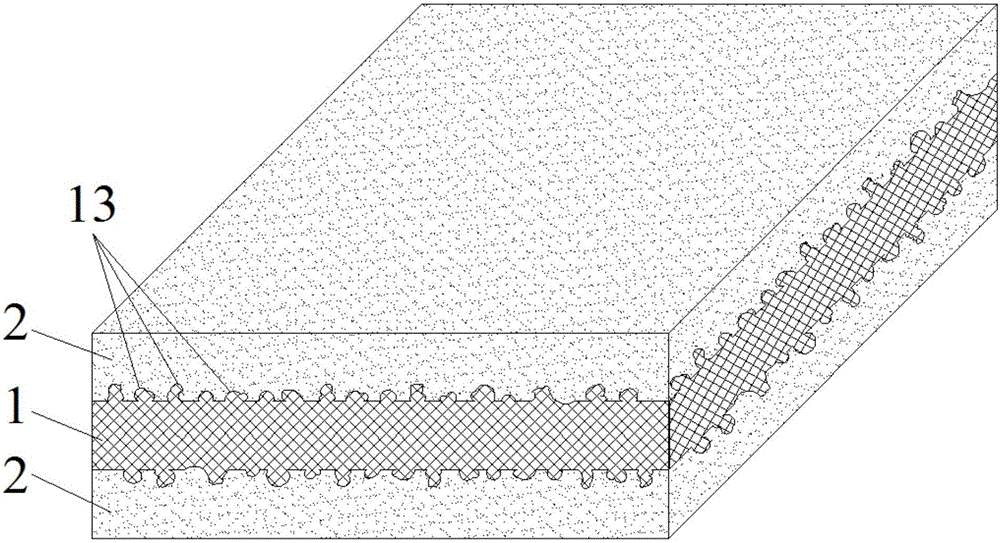

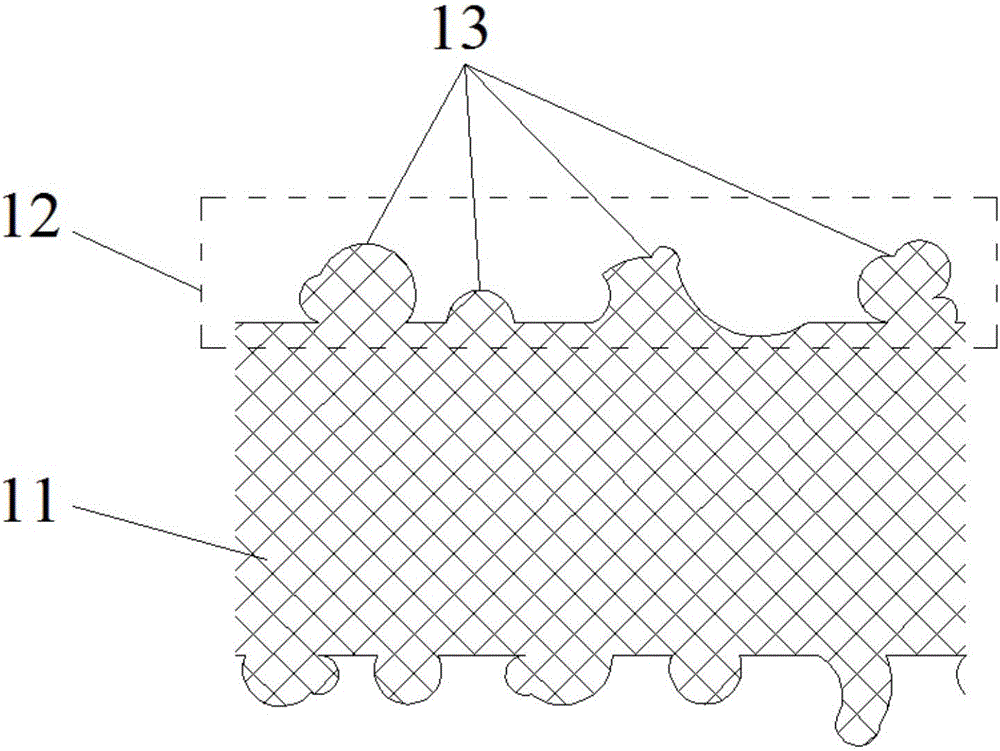

[0025] A preparation method of a natural graphite / copper composite heat sink, specifically carried out according to the following steps: 1, double surface treatment of copper foil, copper foil must be pretreated before roughening treatment, due to the storage process of copper foil during transportation, In the process of transportation, it is in contact with air, hands and other transportation tools, and it is easily polluted by grease and salinity. Moreover, copper has a high surface activity and is easy to form an oxide layer on the surface. Therefore, it is necessary to use an alkaline degreasing agent (such as NaOH, etc.) Oil and pickling (less than 0.5% dilute sulfuric acid) treatment; 2. The treated copper foil is electroplated on both sides in the electroplating solution, so that the surface becomes a layer of nodular copper particles, and at the same time, it is subjected to multiple electroplating roughening treatments to make the nodular The length of the copper part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com