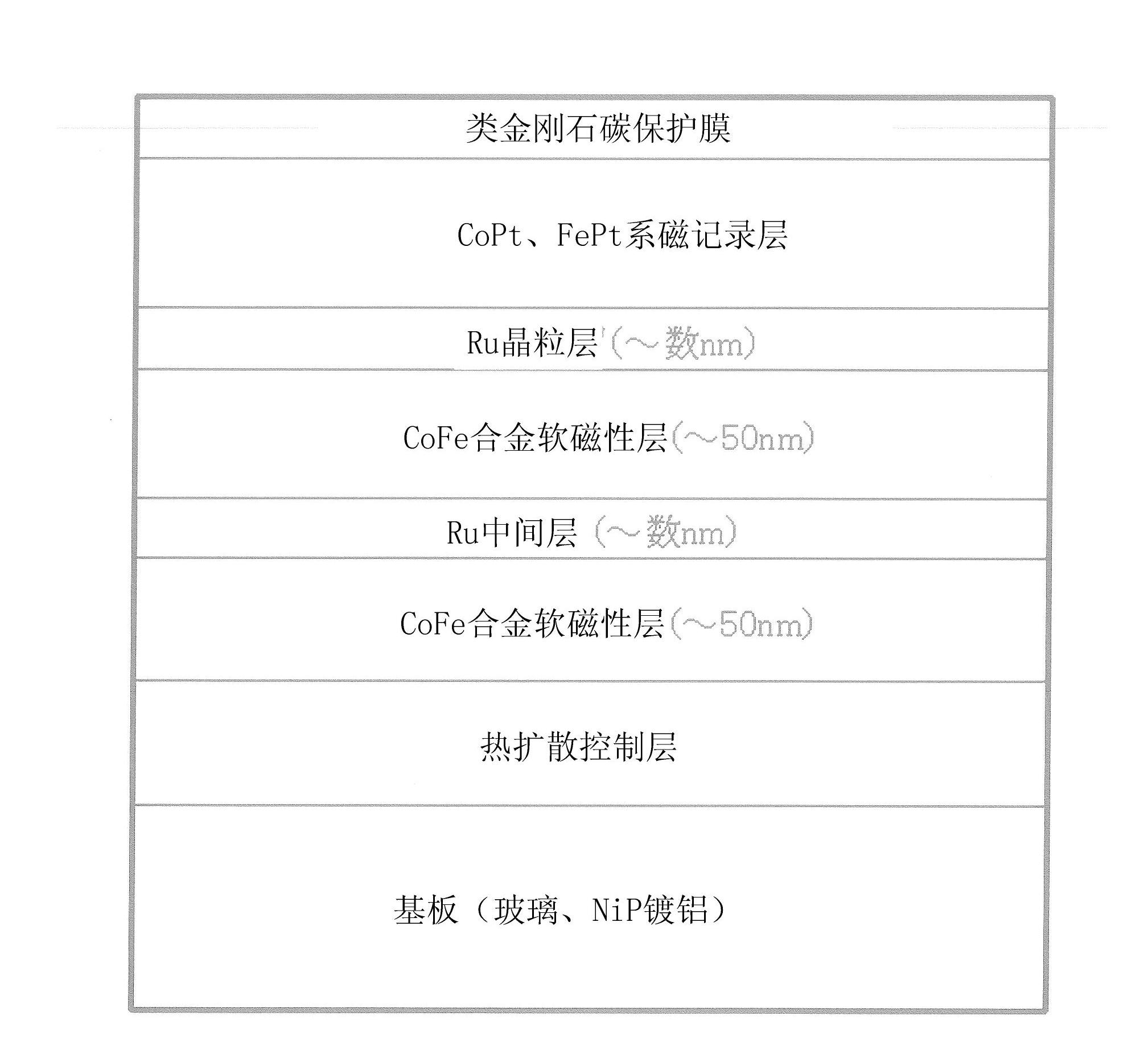

Ag alloy thermal diffusion control film used in magnetic recording medium for thermally assisted recording, magnetic recording medium for thermally assisted recording, and sputtering target

A magnetic recording medium and thermal diffusion technology, applied in magnetic recording, data recording, sputtering coating, etc., can solve the problems of high magnetic crystal anisotropy, magnetic field can not be recorded, etc., to achieve high thermal conductivity and heat resistance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] In this example, the effects of the composition of the Ag alloy thin film on thermal conductivity, thermal diffusivity, and surface smoothness (Ra) were investigated.

[0070] Specifically, various Ag alloy thin films 200 nm described in Table 2 were produced on a glass substrate (CORNING #1737, substrate size: 50 mm in diameter, 1 mm in thickness) using DC magnetron sputtering. Film formation conditions are: substrate temperature: 22°C, Ar pressure: 2mTorr, input power density: 0.025W / cm 2 , Back pressure: -6 Torr.

[0071] In addition, the content of each element in the said Ag alloy was calculated|required by the ICP optical emission analysis (inductively coupled plasma mass spectrometry) method from the sample produced by the film thickness of 100 nm on the glass substrate.

[0072] Using the Ag alloy thin film thus obtained, thermal conductivity, thermal diffusivity, and surface smoothness (Ra) were investigated in the following manner.

[0073] (Measurement of t...

Embodiment 2

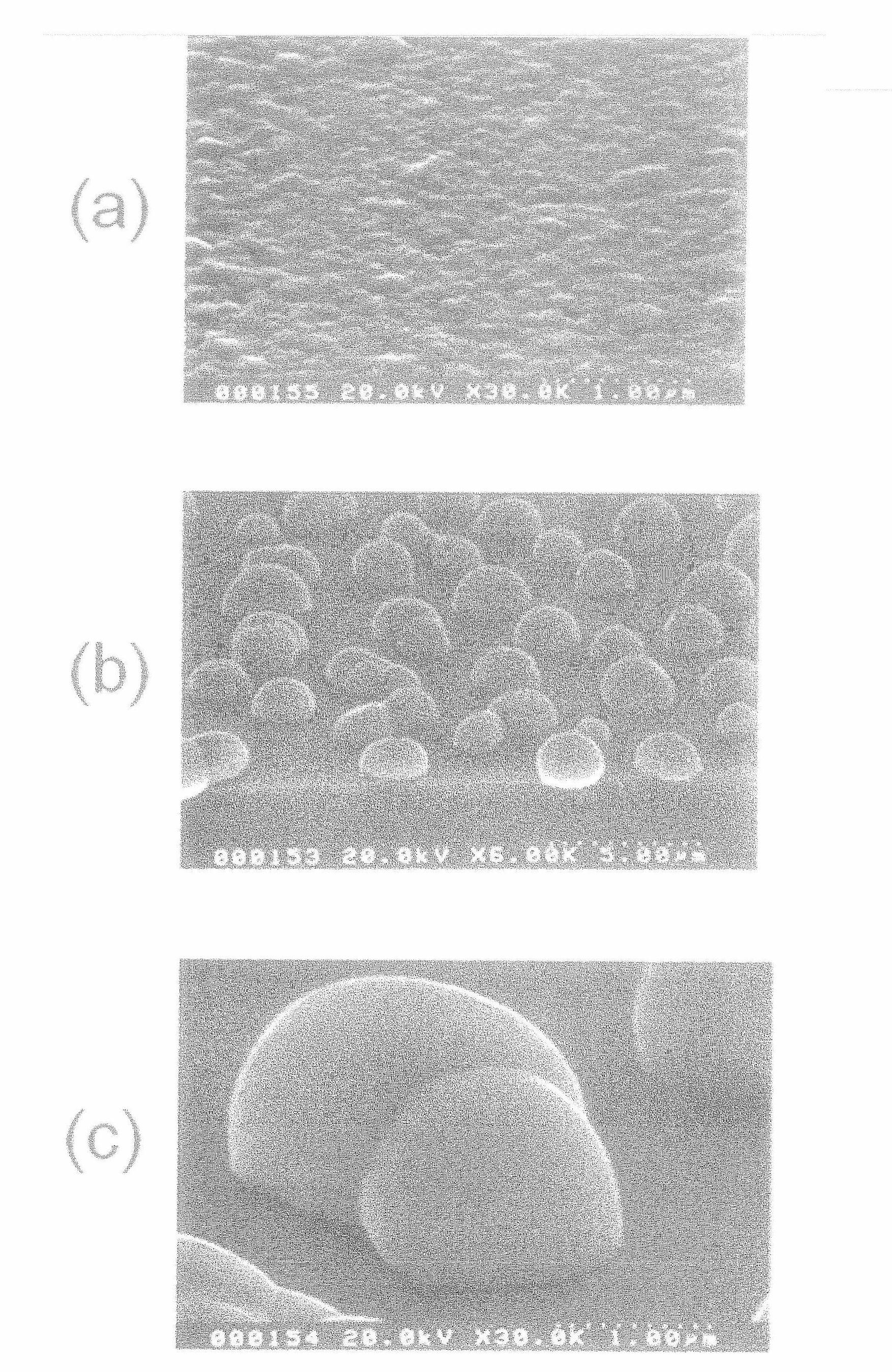

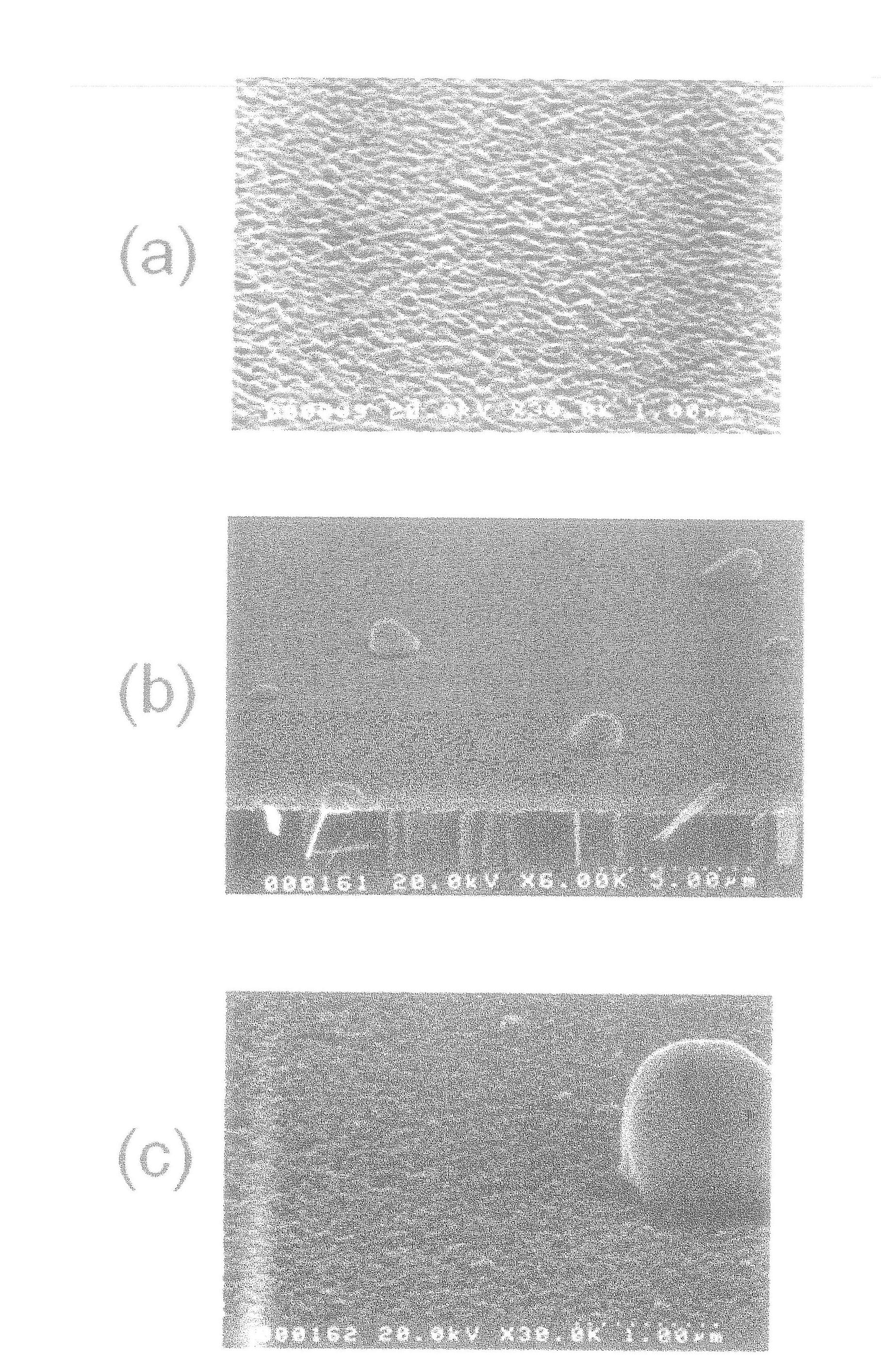

[0086] In this example, various Ag alloy thin films were formed on glass substrates, and the surface shapes after film formation and heat treatment were observed with a scanning reflection electron microscope (SEM).

[0087] In detail, the same as the aforementioned embodiment 1, make image 3 (a)~ image 3 (c) and Figure 4 (a)~ Figure 4 (b) Various Ag alloy films shown in 200nm. The content of the Ag alloy thin film was also calculated in the same manner as in Example 1. Also, for comparison, for pure Ag ( figure 2 (a)~ figure 2 (c)) is also produced in the same manner.

[0088] The heat treatment was performed at 400° C. for 1 hour in the air atmosphere. In the heat-assisted recording method, the heating temperature during actual recording is estimated to be about 100 to 300°C, but in this embodiment, it is set to 400°C as an accelerated test.

[0089] The result is shown in the figure 2 (a)~ figure 2 (c), image 3 (a)~ image 3 (c) and Figure 4 (a)~ Fi...

Embodiment 3

[0094] In this example, using an Ag-0.14 at% Bi-0.2 at% Nd thin film satisfying the requirements of the present invention, the influence of the Ar gas pressure and film thickness during film formation on the surface roughness (Ra) was investigated.

[0095] (About Ag gas pressure)

[0096] In the foregoing embodiment 1, the Ar gas pressure is such as Figure 5 As shown, the surface roughness Ra was varied in the range of 2 to 10 mTorr (film thickness of the Ag alloy thin film = 200 nm), and the surface roughness Ra at this time was measured in the same manner as in Example 1 above. The result is shown in the Figure 5 middle.

[0097] Depend on Figure 5 It can be seen that the surface roughness Ra of the Ag alloy thin film increases sharply when the Ar gas pressure exceeds 5 mTorr. This is presumed to be because the metal particles sputtered from the target are scattered by Ar. Therefore, in order to reduce Ra to 1.0 nm or less specified in the present invention, it is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com