A heat dissipation magnetic insulation tape and a wireless charging power receiver

A power receiver and power receiving technology, applied in the direction of current collectors, battery circuit devices, power electronics modification, etc., can solve the problems of low charging efficiency and large heat generation of wireless chargers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

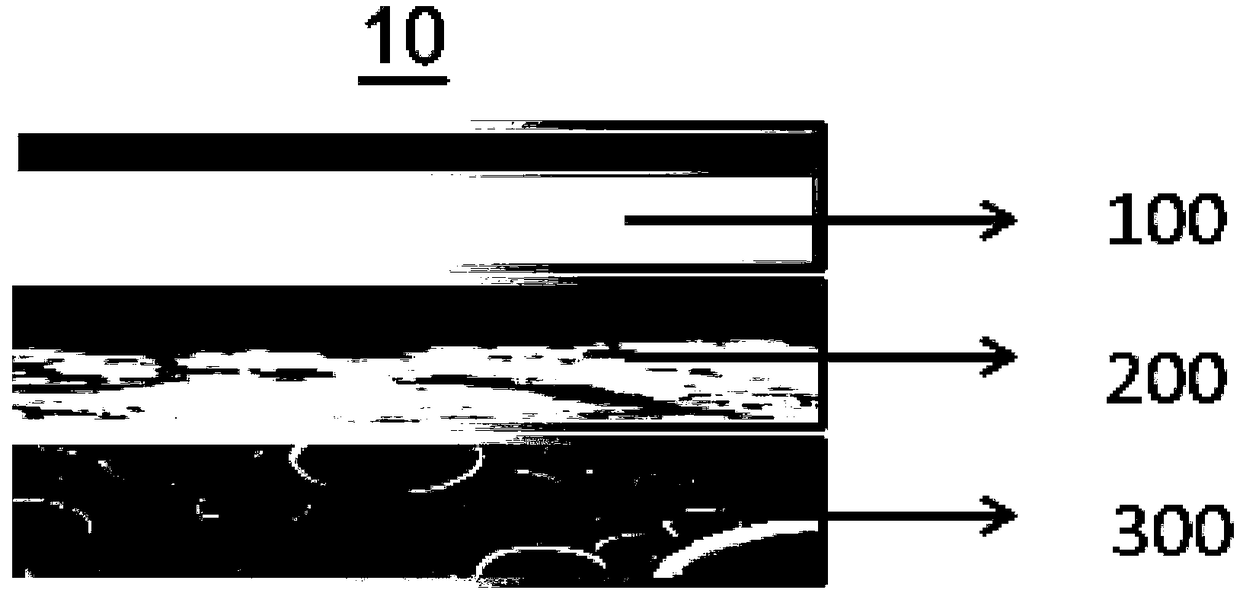

[0038] This embodiment provides a heat dissipation magnetic isolation tape 10, referring to figure 1 As shown, it includes an insulating and protective adhesive layer 100 , a composite heat dissipation adhesive layer 200 , and a magnetic isolation adhesive layer 300 that are stacked. Wherein, the composite heat dissipation adhesive layer 200 is located between the insulating and protective adhesive layer 100 and the magnetic isolation adhesive layer 300 .

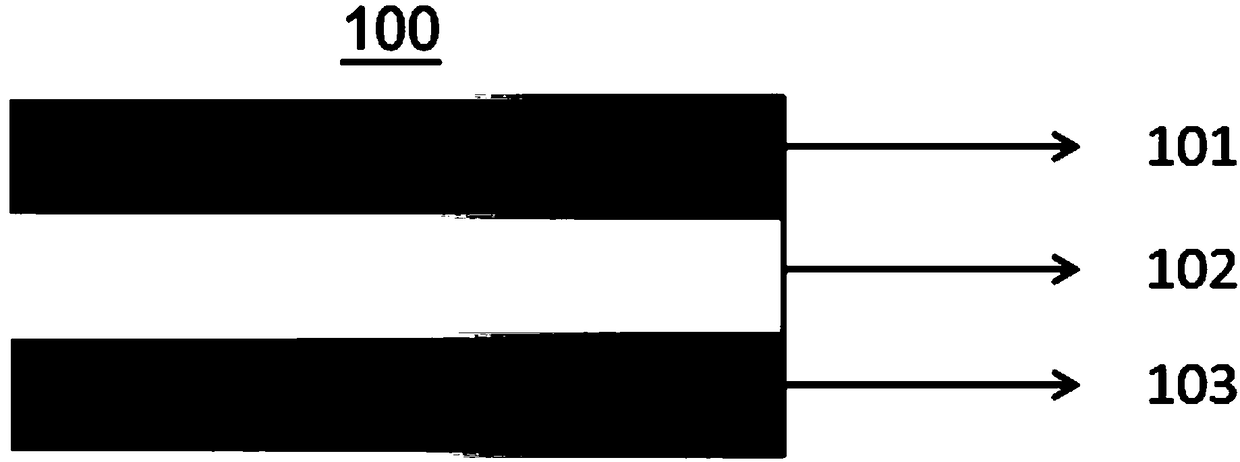

[0039] like figure 2 As shown, the insulating and protective adhesive layer 100 includes an insulating layer 102 , and a first pressure-sensitive adhesive layer 103 is provided on the side of the insulating layer 102 facing the composite heat dissipation adhesive layer 200 . The insulation layer 102 mainly plays the role of insulation protection, and its material can be PET film or PI film. The first pressure-sensitive adhesive layer 103 is used to bond the insulating layer 102 to the composite heat dissipation adhesive ...

Embodiment 2

[0056] This embodiment provides a heat dissipation magnetic isolation tape, which has a layered structure similar to the heat dissipation magnetic isolation tape 10 provided in Example 1, which includes an insulating and protective adhesive layer, a composite heat dissipation adhesive layer and a magnetic isolation adhesive Floor.

[0057] The insulating protective adhesive layer uses a PET film with a thickness of 2 μm as the insulating layer, and the side of the insulating layer away from the composite heat dissipation adhesive layer is coated with a matte black ink layer with a thickness of 1 μm, and the insulating layer is far away from the side of the composite heat dissipation adhesive layer Coated with a first pressure-sensitive adhesive layer with a thickness of 2 μm.

[0058] The composite heat dissipation adhesive layer uses copper foil with a thickness of 9 μm as the metal foil, and the side of the metal foil facing the insulating and protective adhesive layer is co...

Embodiment 3

[0061] This embodiment provides a heat dissipation magnetic isolation tape, which has a layered structure similar to the heat dissipation magnetic isolation tape 10 provided in Example 1, which includes an insulating and protective adhesive layer, a composite heat dissipation adhesive layer and a magnetic isolation adhesive Floor.

[0062] The insulation protection adhesive layer uses a PET film with a thickness of 8 μm as the insulating layer, and the side of the insulating layer away from the composite heat dissipation adhesive layer is coated with a matte black ink layer with a thickness of 4 μm, and the insulating layer is far away from the side of the composite heat dissipation adhesive layer Coated with a first pressure-sensitive adhesive layer with a thickness of 8 μm.

[0063] The composite heat dissipation adhesive layer uses copper foil with a thickness of 20 μm as the metal foil. The side of the metal foil facing the insulating and protective adhesive layer is coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com