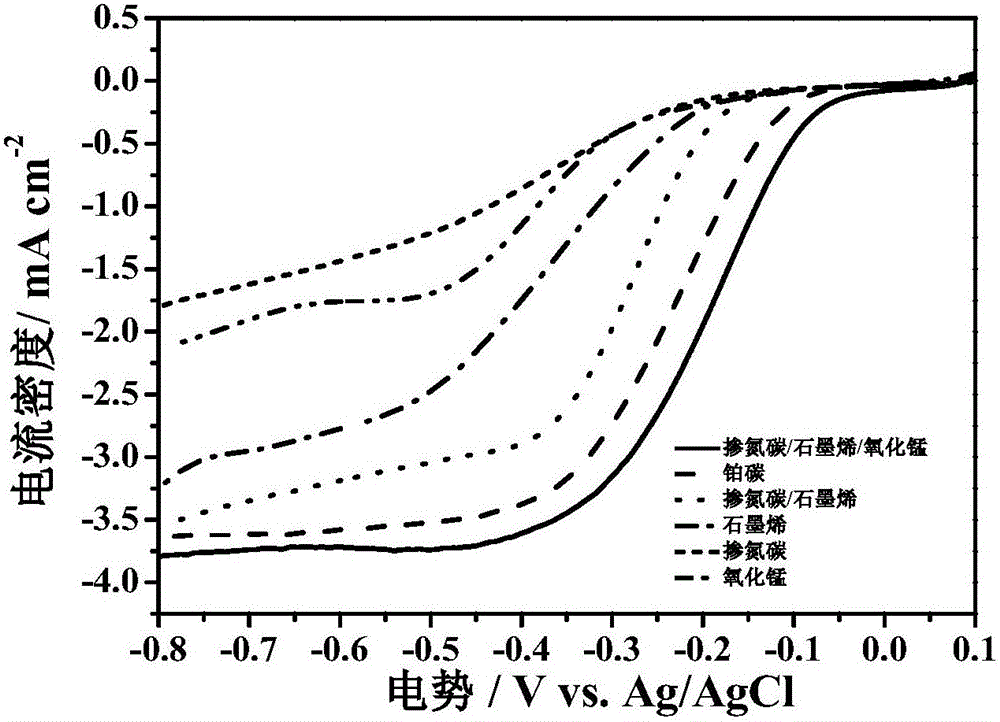

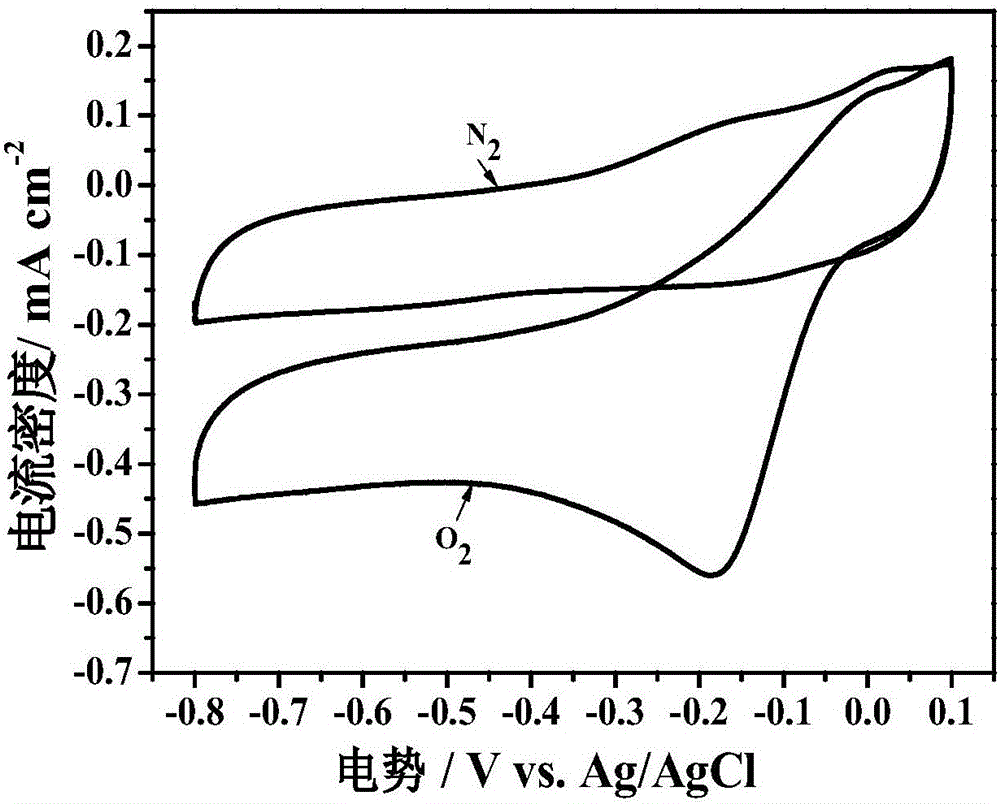

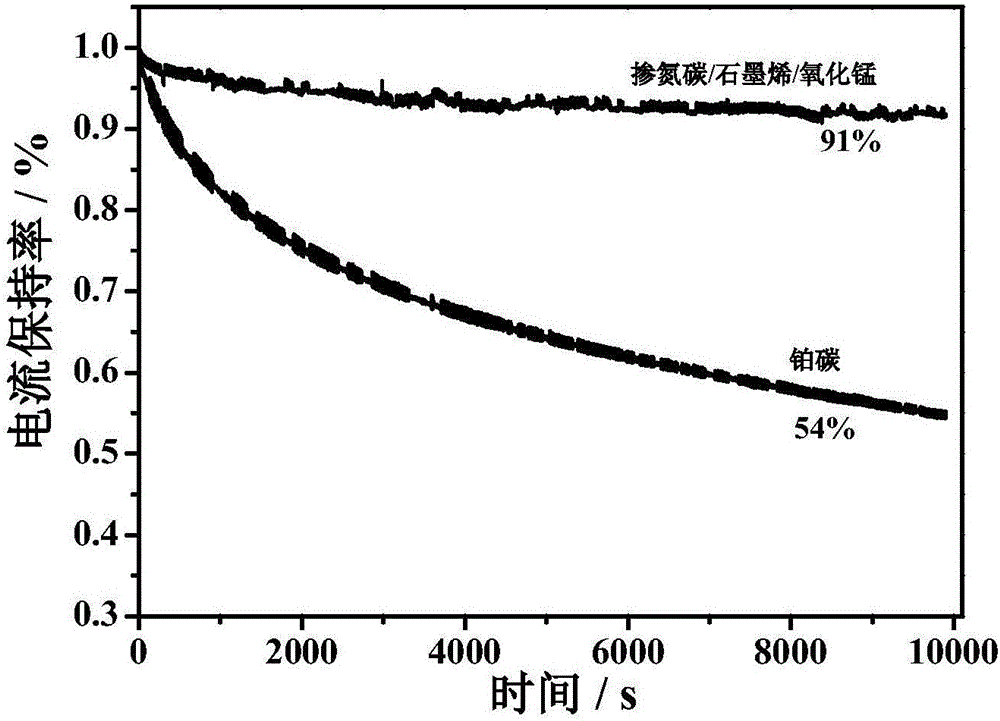

Preparation method of nitrogen-doped carbon/graphene/manganese oxide composite material and application of nitrogen-doped carbon/ graphene/manganese oxide composite material in electrocatalytic reduction of oxygen

A composite material, graphene technology, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as low catalytic efficiency, and achieve excellent oxygen reduction catalytic activity and catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The preparation of nitrogen-doped carbon / graphene / manganese oxide composites and their electrocatalytic activity for oxygen reduction include the following steps:

[0023] (1) 0.1 g of graphene oxide was ultrasonically dispersed in 100 mL of deionized water, and then 0.3 g of m-phenylenediamine monomer was added and ultrasonically mixed for 10 min. Pour the mixture into a three-necked flask, heat it to 95°C for 12 hours, cool to room temperature, then add 0.435g of potassium permanganate solution to the reaction solution, stir for 4 hours, wash and filter, freeze-dry for 24 hours, and finally place the product at 800°C The nitrogen-doped carbon / graphene / manganese oxide composite material was prepared in a tube furnace at a constant temperature for 2 hours. The specific surface area of the material was 486.17m2 by BET test. 2 g -1 .

[0024] (2) The nitrogen-doped carbon / graphene / manganese oxide composite material prepared in step (1) is ultrasonically dispersed, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com