Preparation method of high-speed working condition self-lubricating fabric gasket composite material

A composite material, self-lubricating technology, applied in the field of composite material and self-lubricating, can solve the problems of wear resistance, reduced lubricating performance, increased load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

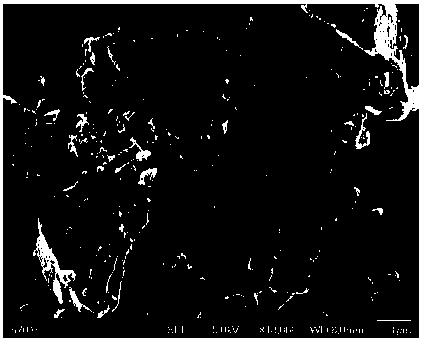

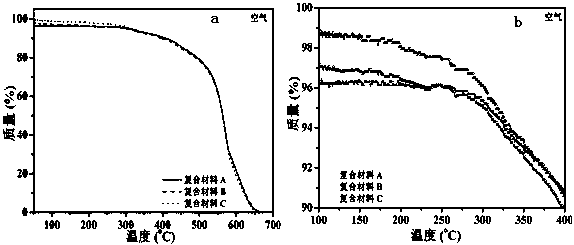

Image

Examples

Embodiment 1

[0067] Preparation of modified basalt scales: soak the commercially available alkaline basalt in 33% silane coupling agent 3-aminopropyltriethoxysilane (KH-550) for 60min, and centrifuge at 1000r / min , dried at 80°C, and passed through a 325-mesh sieve to obtain modified basalt scales;

[0068] Self-lubricating fabric dipping solution A: Take 100g of phenolic resin, disperse it into 900mL of mixed solvent and dilute (V 乙醇 :V 丙酮 =1:1) Obtain self-lubricating fabric impregnating liquid, ultrasonic 0.5h for later use;

[0069] Self-lubricating fabric dipping solution B: Take 100g of phenolic resin, disperse it into 900mL of mixed solvent and dilute (V 乙醇 :V 丙酮=1:1) to obtain a self-lubricating fabric impregnating solution; take 0.5g (0.5% phenolic resin mass fraction) of basalt scales and disperse them in the self-lubricating fabric impregnating solution, and ultrasonicate for 0.5h for later use;

[0070] Self-lubricating fabric dipping solution C: Take 100g of phenolic resin...

Embodiment 2

[0075] Preparation of modified basalt scales: soak the commercially available alkaline basalt in 33% silane coupling agent 3-aminopropyltriethoxysilane (KH-550) for 60min, and centrifuge at 1000r / min , dried at 80°C, and passed through a 325-mesh sieve to obtain modified basalt scales;

[0076] Self-lubricating fabric dipping solution A: Take 100g of phenolic resin, disperse it into 900mL of mixed solvent and dilute (V 乙醇 :V 丙酮 =1:1) Obtain self-lubricating fabric impregnating liquid, ultrasonic 0.5h for later use;

[0077] Self-lubricating fabric dipping solution C: Take 100g of phenolic resin, disperse it into 900mL of mixed solvent and dilute (V 乙醇 :V 丙酮 =1:1) to obtain a self-lubricating fabric impregnating solution; take 0.5g (mass fraction of phenolic resin 0.5%) of basalt scales and 3g of fluorinated graphite (mass fraction of phenolic resin 3%) and disperse them in the self-lubricating fabric impregnating solution, ultrasonic 0.5 h standby;

[0078] Take three pie...

Embodiment 3

[0083] Commercially available basalt flakes prepared from alkaline basalt were pulverized. Soak basalt scales in 33% silane coupling agent 3-aminopropyltriethoxysilane (KH-550) for 60 minutes, centrifuge at 1000r / min, dry at 80°C, pass through 325 mesh Sieve to obtain modified basalt scales.

[0084] Self-lubricating fabric dipping solution A: Take 100g of phenolic resin, disperse it into 900ml of mixed solvent and dilute it (V 乙醇 :V 丙酮 =1:1) Obtain self-lubricating fabric impregnating liquid, ultrasonic 0.5h for later use;

[0085] Self-lubricating fabric dipping solution C: Take 100g of phenolic resin, disperse it into 900ml of mixed solvent and dilute it (V 乙醇 :V 丙酮 =1:1) to obtain a self-lubricating fabric impregnating solution; take 0.5g (mass fraction of phenolic resin 0.5%) of basalt scales and 3g of fluorinated graphite (mass fraction of phenolic resin 3%) and disperse them in the self-lubricating fabric impregnating solution, ultrasonic 0.5 h standby;

[0086] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com