Polyester amide reverse osmosis compound film and its preparation method

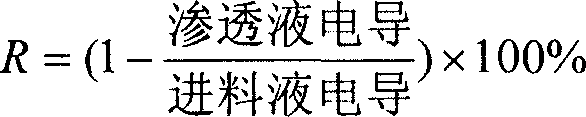

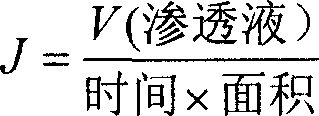

A technology of reverse osmosis composite membrane and polyester amide, which is applied in the field of polyester amide reverse osmosis composite membrane and its preparation, and can solve problems such as unsatisfactory desalination rate and water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 2% (wt%) glucosamine and 0.1% (wt%) sodium dodecyl sulfate are formulated into an aqueous solution, and the pH is adjusted to 12 with sodium hydroxide; trimesic acid chloride (TMC) is dissolved in n-hexane to prepare into a 0.1% (wt%) organic phase solution. Immerse the polysulfone supported membrane on one side in a 2% aqueous solution for 3 minutes; drain off excess aqueous solution and react with the organic phase for 30 seconds; drain off the organic phase and dry in air for 1 minute; Heat treatment at 75° C. for 3 minutes in a box; rinse with deionized water to obtain a reverse osmosis composite membrane.

[0022] The reverse osmosis composite membrane prepared above was dried, and its infrared absorption was measured with an attenuated total reflection Fourier transform infrared spectrometer. It was found that: 1663cm -1 , 1540cm -1 There is absorption at amide I band and amide II band characteristic peaks, respectively, which proves the formation of amide bond...

Embodiment 2

[0024] Following the same procedure as Example 1, a reverse osmosis composite membrane was prepared. The composition of the aqueous phase is: 1.2% (wt%) m-phenylenediamine, 0.8% (wt%) glucosamine and 0.1% (wt%) sodium dodecyl sulfate, pH=12 is adjusted with sodium hydroxide; the organic phase is 0.1% (wt%) of TMC was dissolved in n-hexane to prepare; the polysulfone support membrane was immersed in the aqueous phase solution on one side for 3 minutes; the excess aqueous solution was drained, and the organic phase was reacted for 60 seconds; the organic phase was drained , and dried in air for 3 minutes; heat-treated at 85° C. for 5 minutes in a blast drying oven; rinsed with deionized water to obtain a reverse osmosis composite membrane.

[0025] The properties were determined as previously described. At the concentration of 20000mg / L sodium chloride aqueous solution, the operating pressure is 1.6MPa, and the temperature is 25℃, the flux is 29.3L / m 2 h, the salt rejection ra...

Embodiment 3

[0027] Following the same procedure as Example 1, a reverse osmosis composite membrane was prepared. The composition of the aqueous phase is: 1.2% (wt%) m-phenylenediamine, 0.8% (wt%) glucosamine and 0.1% (wt%) sodium dodecyl sulfate, pH=12 is adjusted with sodium hydroxide; the organic phase is 0.2% (wt%) TMC dissolved in C 12 Prepared in solvent oil; immerse the polysulfone support membrane in the aqueous phase solution on one side for 3 minutes; drain off the excess aqueous solution, and react with the organic phase for 60 seconds; drain the organic phase and dry it in the air for 5 minutes; Heat treatment at 85°C for 10 minutes in a blast drying oven; rinse with deionized water to obtain a reverse osmosis composite membrane.

[0028] The properties were determined as previously described. At the concentration of 20000mg / L sodium chloride aqueous solution, the operating pressure is 1.6MPa, and the temperature is 25℃, the flux is 20.9L / m 2 ·h, the salt rejection rate was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com