Easy-split contracted film, easy-split laminated film, easy-split bag, and manufacturing method for easy-split contracted film

A technology of shrink film and manufacturing method, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of inner peeling, large inner peeling, unstable strength of laminated film, etc. Excellent properties, excellent linear cutoff, excellent effect of anti-peeling effect in the layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

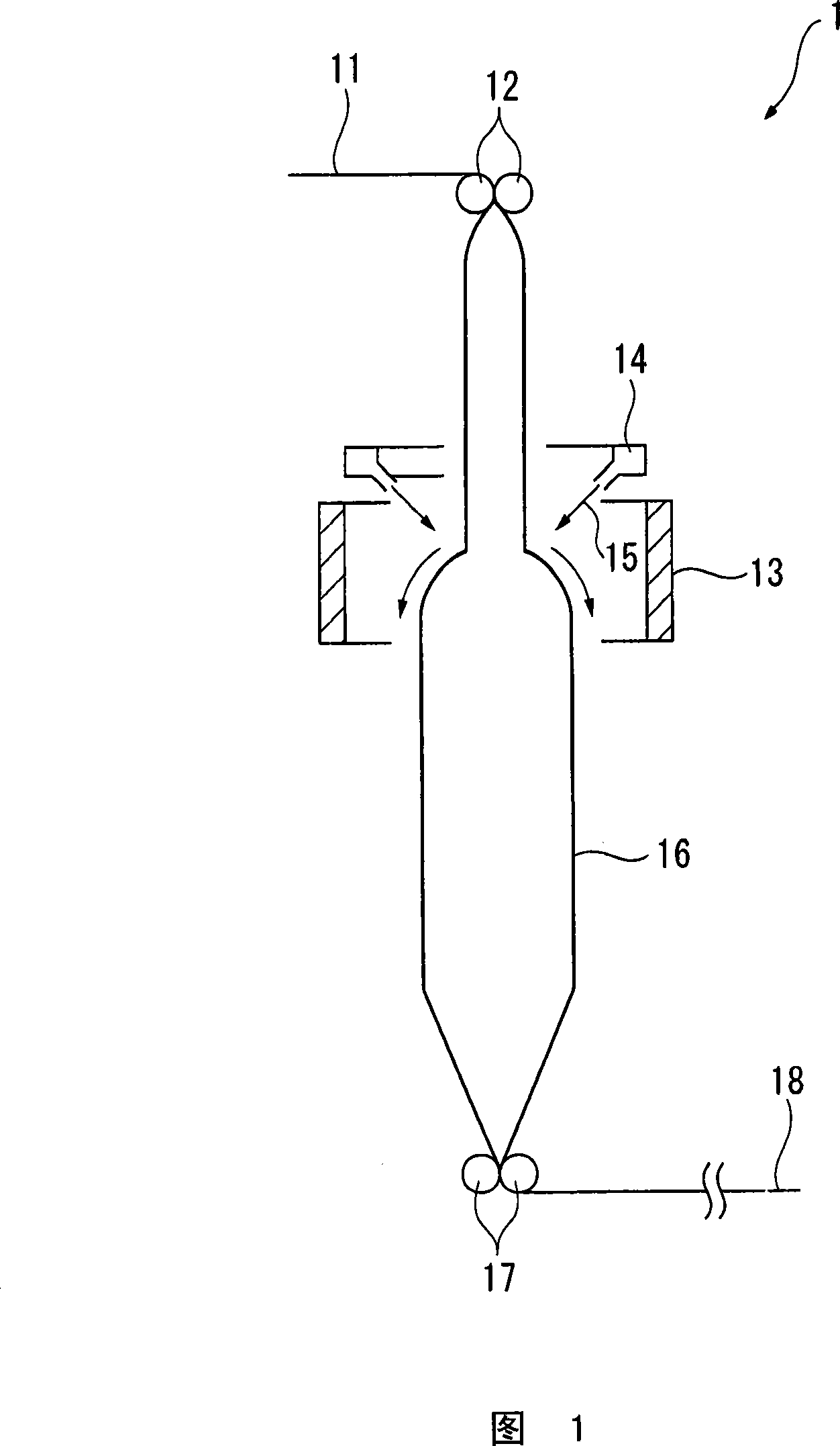

[0073] (Manufacture of breakable shrink film)

[0074] In the mixture that is mixed with Ny6 granule and MXD6 granule in the ratio of 70 mass parts and 30 mass parts respectively, mix with 15 mass % of raw material total amount and have once-in-a-time melt-mixing and make the thermal experience product of granule with this mixing ratio (MXD6 The melting point is 236°C). After melting and kneading the dry mixture in an extruder at 270° C., the melted product was extruded from a die in the form of a cylindrical film, followed by quenching with water to prepare a film blank.

[0075] Among them, the melting point of MXD6 was measured by using a differential scanning calorimeter (DSC) manufactured by Perkin Elma Co., Ltd., from 50° C. to 280° C. at a heating rate of 10° C. / min. All values are melting points in the first melting.

[0076] Ny6 used as Ny6 manufactured by Ube Industries, Ltd. [UBE Nylon 1023FD (trade name), relative viscosity μr=3.6], used as MXD6 was manufacture...

Embodiment 2~8

[0106] [Examples 2-8, Comparative Examples 1-7]

[0107] In the above-mentioned embodiment 1, the mixing amount of Ny6 particles, MXD6 particles and heat history products and the melting point of MXD6 in heat history products are changed, and the heat fixing conditions after stretching are changed simultaneously, and the same manufacturing process as in embodiment 1 is carried out. film forming. An evaluation test was also performed in the same manner as in Example 1. Table 1 shows the production conditions and evaluation results of Examples, and Table 2 shows the production conditions and evaluation results of Comparative Examples.

[0108] Table 1

[0109] Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

Example 8

Ne6

(parts by mass)

70

70

70

70

70

70

70

80

MXD6

(parts by mass)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com