Production method of high-strength high-modulus PMIA super-short fiber

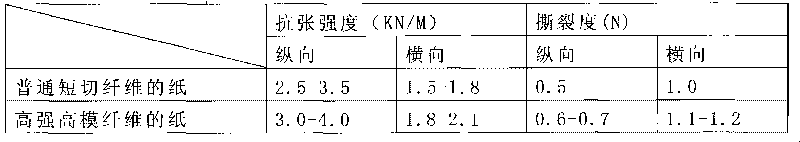

An ultra-short fiber, high-strength and high-modulus technology, applied in the direction of wet spinning, single-component polyamide rayon, etc., can solve the problems of unsatisfactory strength and modulus of aramid paper, and achieve high strength and modulus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. Carry out solution polymerization with monomeric isophthaloyl chloride (IPC) and monomeric m-phenylenediamine (MPDA) in the solution of dimethylacetamide, and use calcium hydroxide to neutralize the hydrochloric acid generated by the reaction to obtain spinning silk stock solution;

[0014] The spinning solution used before wet spinning is a low-salt spinning solution. When carrying out the polymerization reaction, isophthaloyl chloride is added once for neutralization. By controlling the amount of isophthaloyl chloride added and adding a suitable terminator, the The inherent viscosity of the spinning dope is 4.3-4.6.

[0015] 2. Wet spinning: After degassing, the spinning stock solution is extruded through a spinneret hole with a diameter of 0.01-2 mm, and the filament is formed through an aqueous solution at a temperature of 20 ° C, and passed through a special drafting machine in a In an aqueous solution containing calcium chloride, draw twice to make it have goo...

Embodiment 2

[0019] 1. In the solution of dimethylformamide, use monomer isophthaloyl chloride (IPC) and monomer m-phenylenediamine (MPDA) to carry out solution polymerization, and use calcium oxide to neutralize the hydrochloric acid generated by the reaction to obtain spinning Stock solution; The logarithmic viscosity of the spinning stock solution is 4.6-4.9.

[0020] 2. Wet spinning: After degassing, the spinning stock solution is re-extruded through a spinneret hole with a diameter of 0.01-2 mm, and a filament is formed through an aqueous solution at a temperature of 40 ° C, and passed through a special drafting machine in a In an aqueous solution containing calcium chloride, the draft is 6 times to make it have good mechanical properties, and the fiber is washed and dried;

[0021] 3. Heat treatment at 400°C on the dried product;

[0022] 4. After heat treatment, the fibers are wound into high-strength and high-modulus meta-aramid filament bundles, and then cut with a special cuttin...

Embodiment 3

[0024] 1. Carry out solution polymerization with monomeric isophthaloyl chloride (IPC) and monomeric m-phenylenediamine (MPDA) in the solution of dimethylacetamide, and use calcium hydroxide to neutralize the hydrochloric acid generated by the reaction to obtain spinning Silk stock solution; the logarithmic viscosity of the spinning stock solution is 5.4-5.7.

[0025] 2. Wet spinning: After degassing, the spinning stock solution is re-extruded through a spinneret hole with a diameter of 0.01-2 mm, and a filament is formed through an aqueous solution at a temperature of 50 ° C, and passed through a special drafting machine in a In an aqueous solution containing calcium chloride, draw 10 times to make it have good mechanical properties, wash and dry the fiber;

[0026] 3. Heat treatment at 450°C on the dried product to further improve the mechanical properties of the fiber;

[0027] 4. After heat treatment, the fibers are wound into high-strength and high-modulus meta-aramid fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com