Method for improving water flux and anti-pollution capacity of polyamide reverse osmosis membrane

A technology of reverse osmosis membrane and polyamide, which is used in osmosis/dialysis water/sewage treatment, semi-permeable membrane separation, water/sewage treatment, etc., can solve the problem of low water flux and poor anti-pollution ability of polyamide composite reverse osmosis membrane and other problems, to achieve the effect of strong anti-pollution ability and improved water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

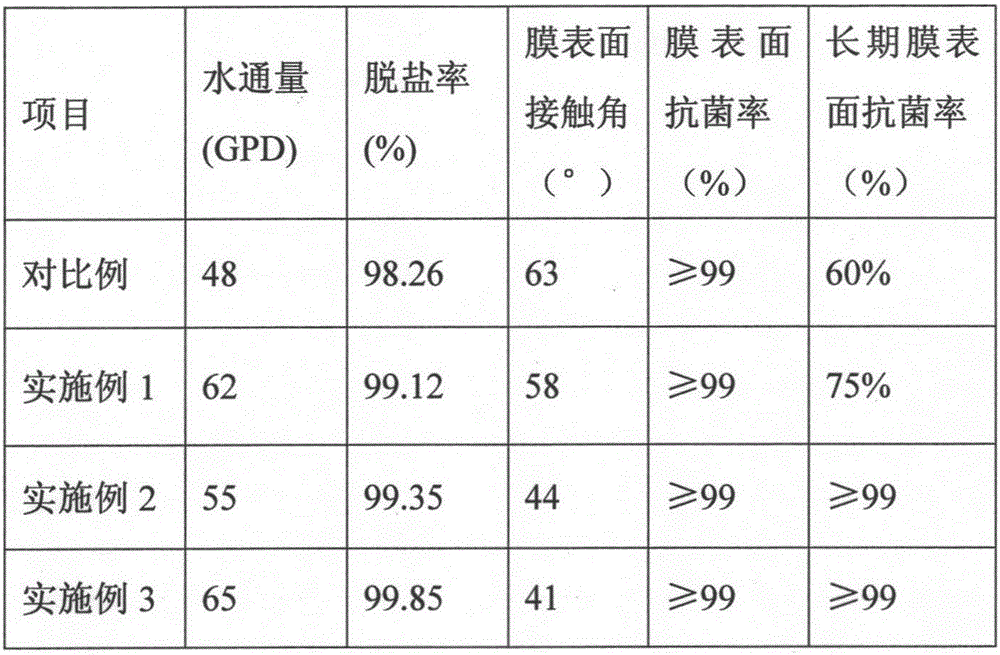

Embodiment 1

[0014] Dissolve 20 parts by weight of polysulfone (P3500) in N-N, dimethylacetamide solution, add 0.2 parts of sodium dodecylsulfonate, mix well, apply it on the surface of non-woven fabric, immerse in water, remove solvent to obtain a porous support layer. The polysulfone support layer was immersed in 3% hydrogen peroxide solution, and treated with ultraviolet light for 10 minutes. Rinse the surface of the support layer repeatedly with deionized water, and after air-drying, immerse it in an aqueous solution with a concentration of m-phenylenediamine of 2%, and contact for 40s to form an aqueous phase liquid layer on the surface of the porous support layer to obtain a wet film; immerse the wet film in In the naphtha organic solution containing 0.05% trimellitic acid chloride, contact with it for 30s, interfacial polymerization reaction occurs with it, dry in an oven at 100°C for 2min, wash with deionized water several times, and obtain the treated polyamide composite Reverse ...

Embodiment 2

[0016] Dissolve 20 parts by weight of polysulfone (P3500) in N-N, dimethylacetamide solution, add 0.2 parts of sodium dodecylsulfonate, mix well, apply it on the surface of non-woven fabric, immerse in water, remove solvent to obtain a porous support layer. Rinse the surface of the support layer repeatedly with deionized water, and after air-drying, immerse it in an aqueous solution with a concentration of m-phenylenediamine of 2%, and contact for 40s to form an aqueous phase liquid layer on the surface of the porous support layer to obtain a wet film; immerse the wet film in In the naphtha organic solution containing 0.05% trimellitic acid chloride, contact with it for 30s, interfacial polymerization reaction occurs with it, dry in an oven at 100°C for 2 minutes, and wash with deionized water several times to obtain the treated polyamide Composite reverse osmosis membrane. Immerse the polyamide composite reverse osmosis membrane in an aqueous solution with a sodium sulfate c...

Embodiment 3

[0018] Dissolve 20 parts by weight of polysulfone (P3500) in N-N, dimethylacetamide solution, add 0.2 parts of sodium dodecylsulfonate, mix well, apply it on the surface of non-woven fabric, immerse in water, remove solvent to obtain a porous support layer. The polysulfone support layer was immersed in 3% hydrogen peroxide solution, and treated with ultraviolet light for 10 minutes. Wash it several times with deionized water, and after air-drying, immerse it in an aqueous solution with a concentration of m-phenylenediamine of 2%, and contact it for 40 seconds to form an aqueous phase liquid layer on the surface of the porous support layer to obtain a wet film; In the naphtha organic solution of 0.05% phenyltrimethyl acid chloride, contact with it for 30s, and interfacial polymerization reaction occurs with it, after drying in an oven at 100°C for 2 minutes, wash it several times with deionized water, and obtain the polyamide composite reaction after treatment. permeable membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com