Patents

Literature

40results about How to "Simplify recycling steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite extraction system for extracting lithium from lithium containing bittern and extraction method of composite extraction system

The invention discloses a composite extraction system for extracting lithium from lithium containing bittern and an extraction method of the composite extraction system. The composite extraction system is loaded with 2.5 g / L-10.4 g / L of Fe (III), 10%-60% of an extraction agent A and 10%-30% of an extraction agent B are included, and the balance is diluent, wherein the extraction agent A is a neutral phosphine extraction agent and / or an amides extraction agent, the extraction agent B is an acid phosphine extraction agent, and the percent is the volume percent occupied in the composite extraction system. The composite extraction system can effectively extract lithium from the lithium containing bittern, lithium reverse extraction can effectively conducted especially when the pH ranges from 1.0 to 1.8, the corrosivity to equipment due to peracid reverse extraction is avoided, and lithium is easily recycled in the reverse extraction liquid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

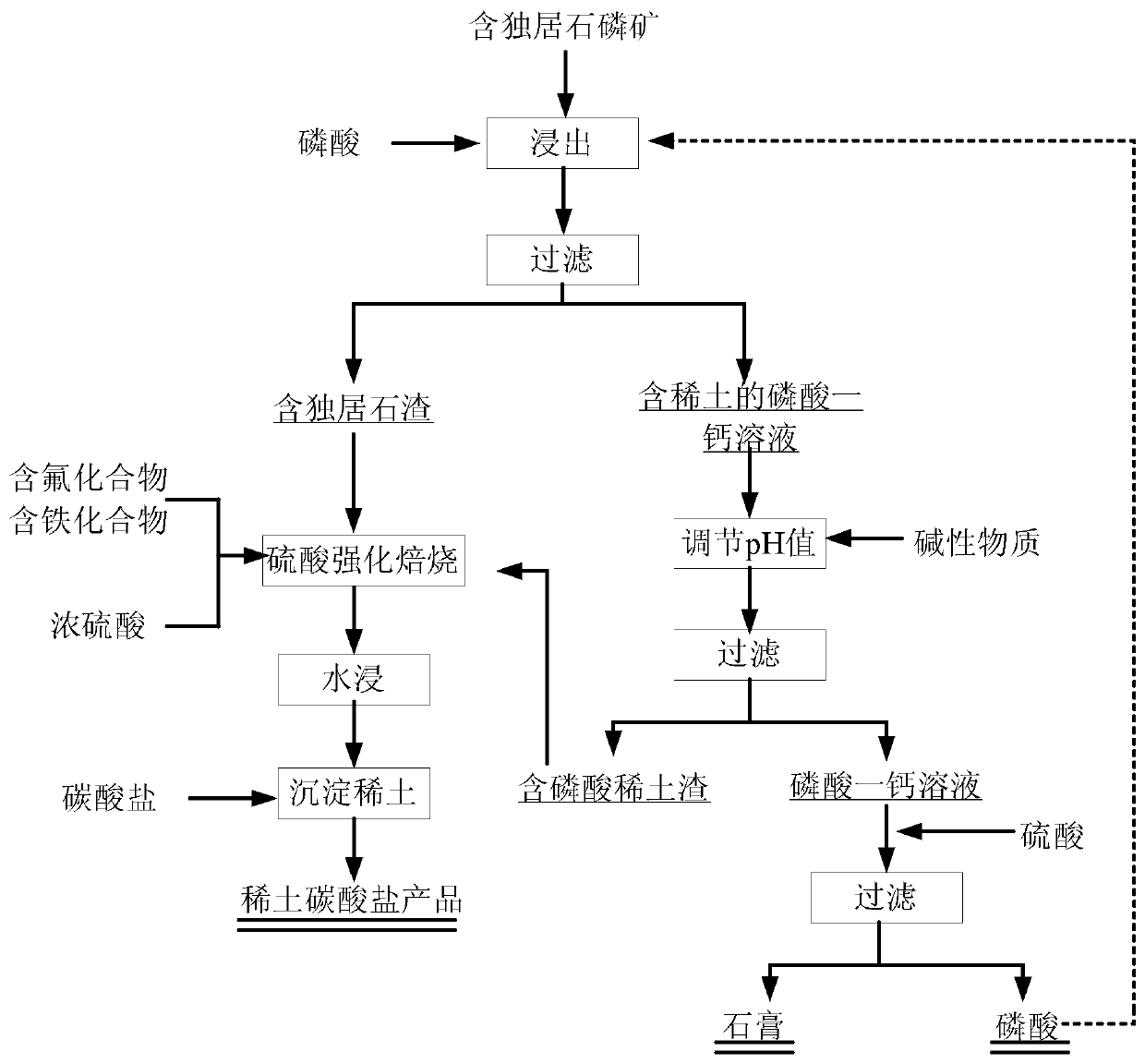

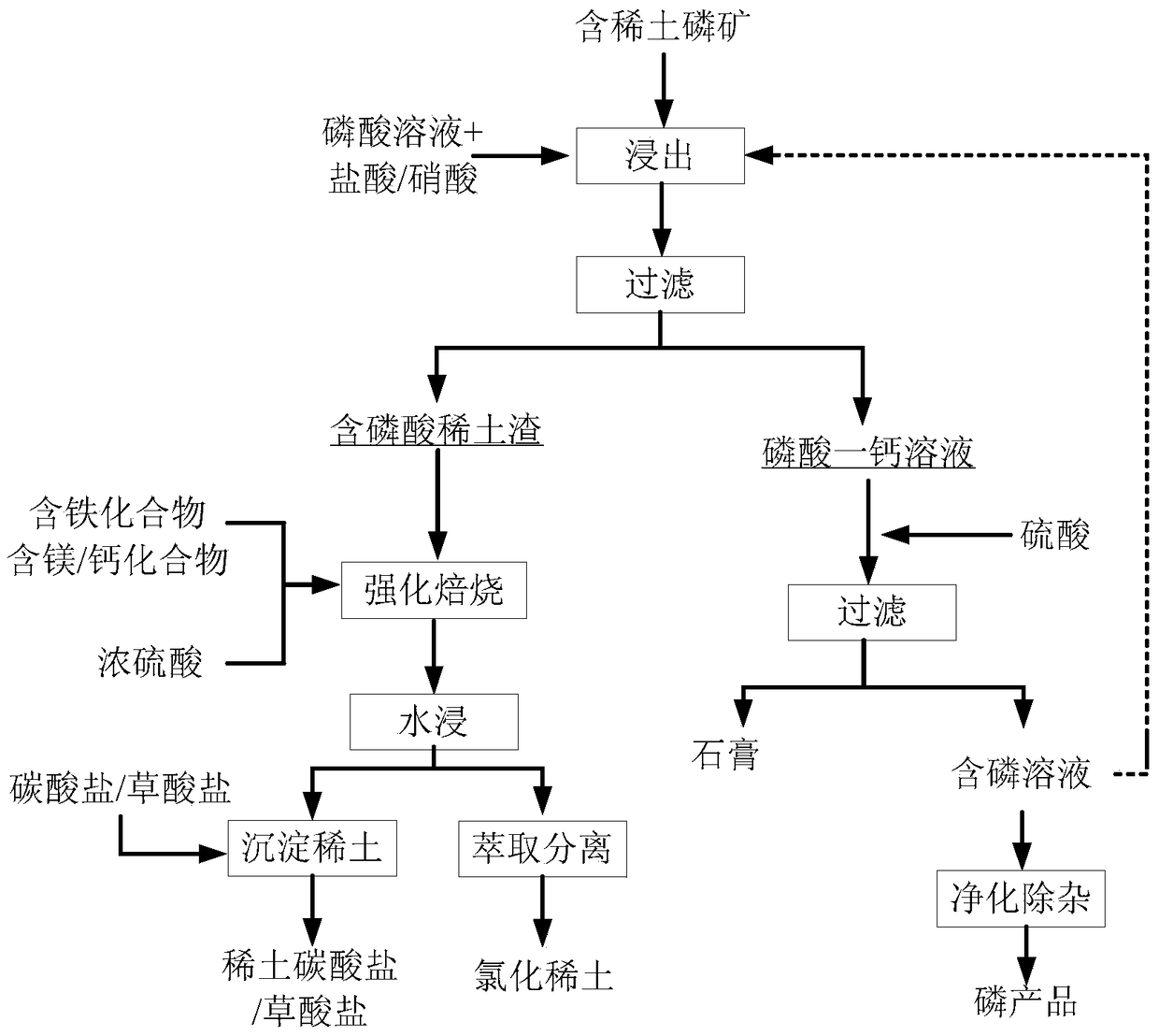

Method for comprehensively recycling phosphorus and rare earth from rare earth phosphorite containing monazite

ActiveCN105331812AHigh recovery rateEfficient separationProcess efficiency improvementRaw phosphate material treatmentSolubilitySlag

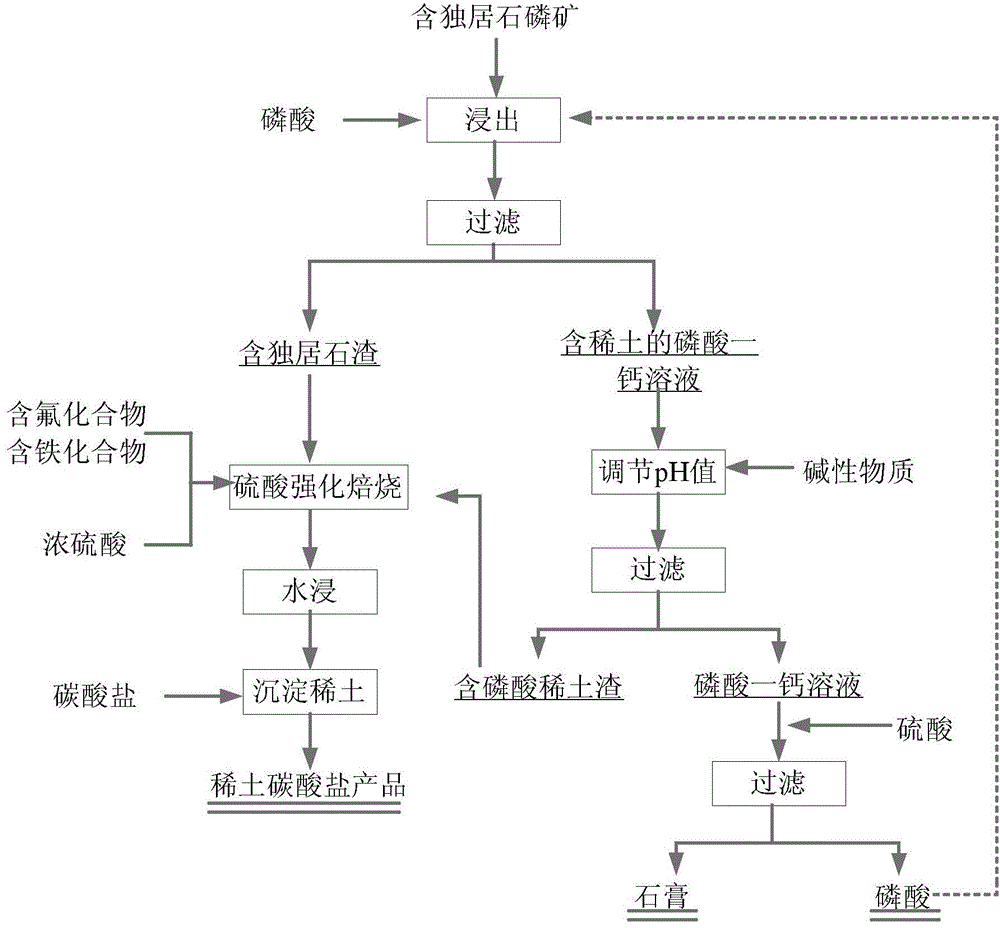

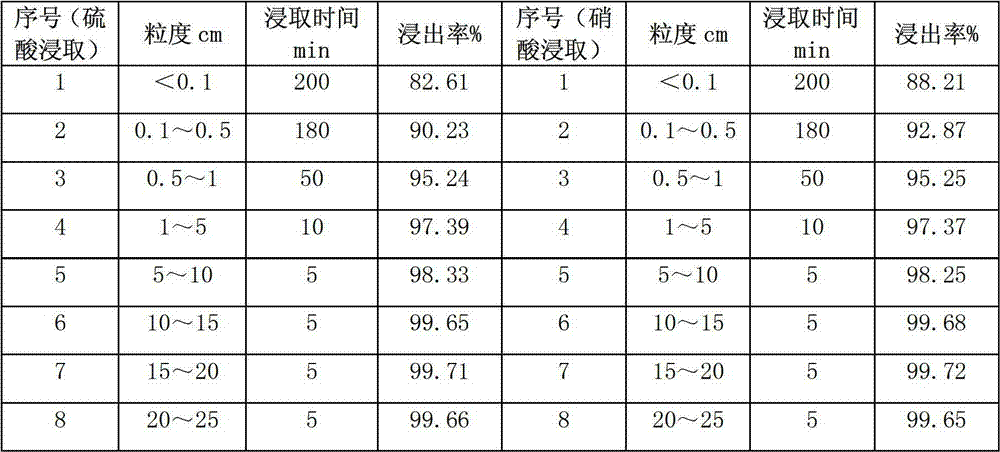

The invention discloses a method for comprehensively recycling phosphorus and rare earth from rare earth phosphorite containing monazite. The method includes the following steps that rare earth phosphorite containing monazite is obtained from phosphoric acid in a leaching manner, and a monocalcium phosphate solution containing rare earth and slag containing monazite are obtained through filtration; the monocalcium phosphate solution containing rare earth is processed through a precipitation method, dissolved rare earth precipitates, a monocalcium phosphate solution and rare earth slag containing phosphoric acid are obtained through filtration, and the rare earth slag containing phosphoric acid and slag containing monazite are mixed to form mixed slag; and phosphorus in the monocalcium phosphate solution is recycled, and rare earth in the mixed slag is recycled. Acid leaching is conducted by adding phosphoric acid, phosphorus in rare earth phosphorite containing monazite forms monocalcium phosphate high in solubility, and therefore monazite existing in a precipitation manner and phosphorus can be separated. Then, the monocalcium phosphate solution containing rare earth is processed through the precipitation method, and rare earth and phosphorus elements in phosphorite can be effectively separated. Rare earth and phosphorus are effectively separated through two times of separation steps, and therefore the rare earth recycling rate is increased.

Owner:GRIREM ADVANCED MATERIALS CO LTD

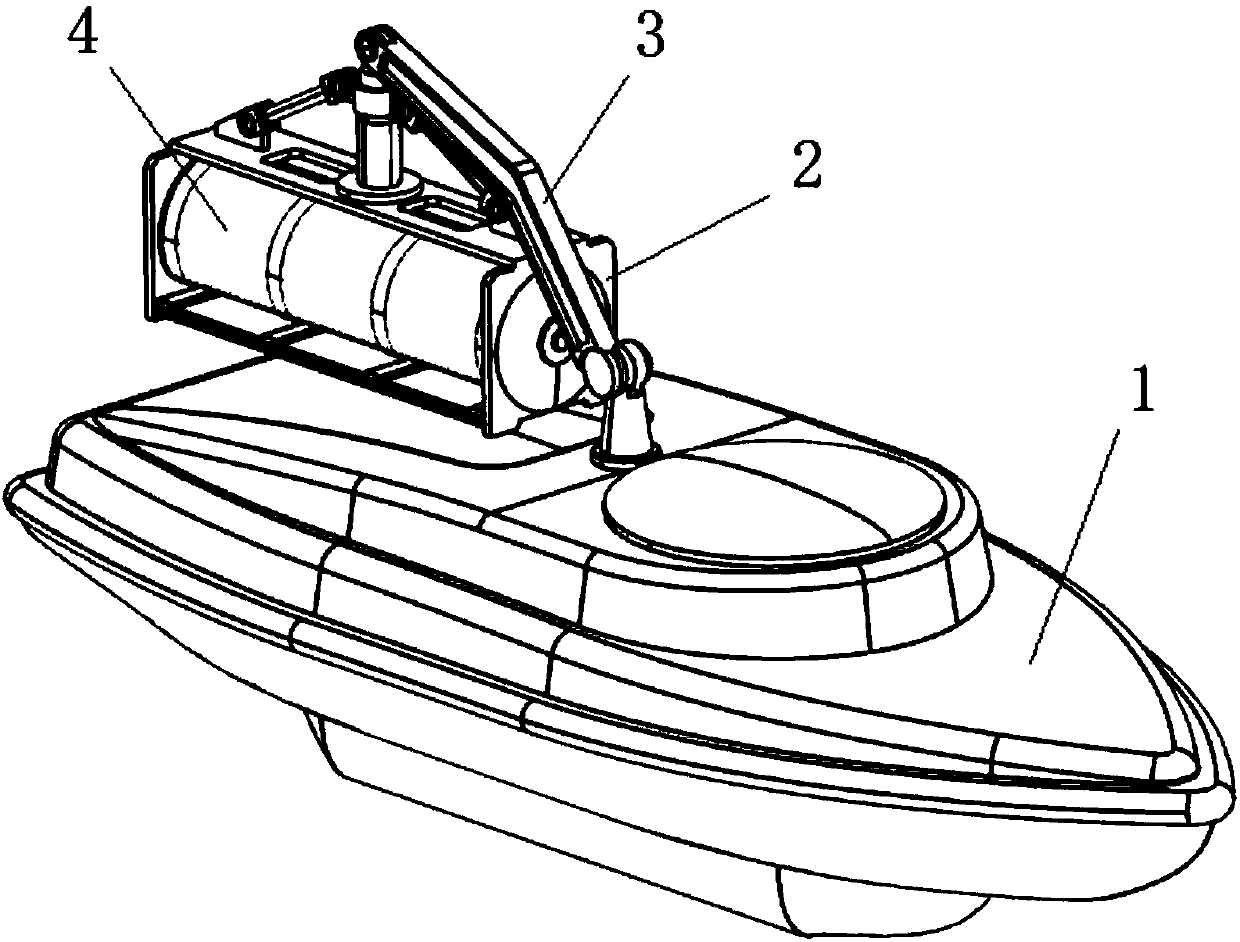

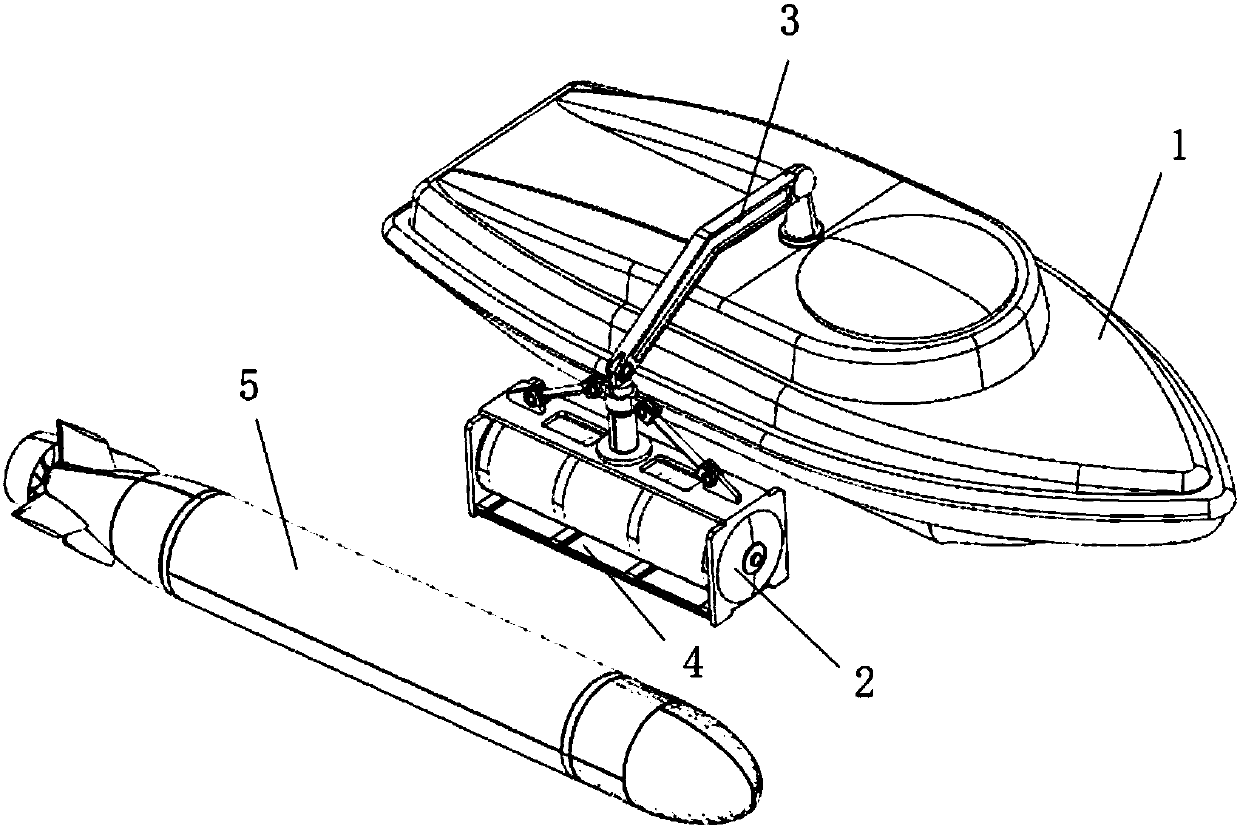

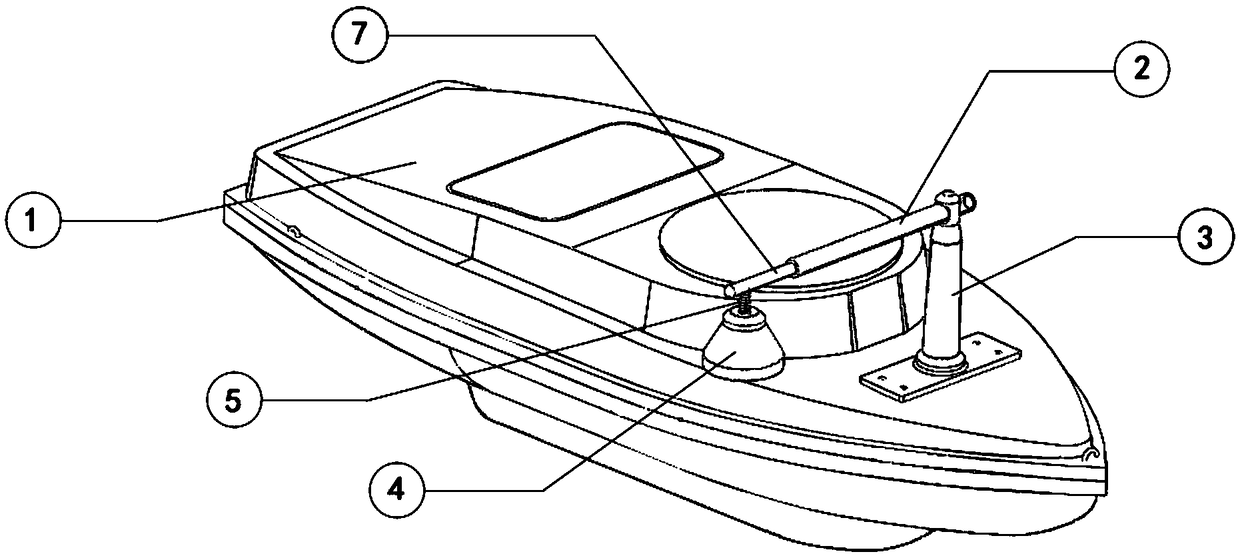

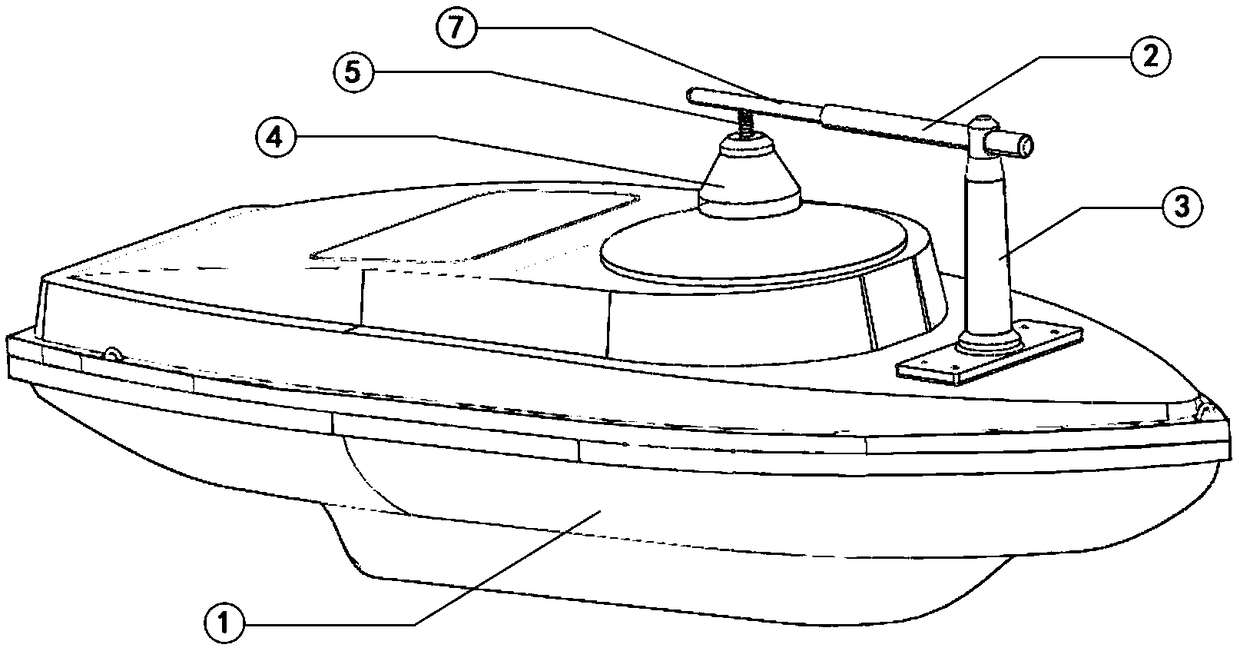

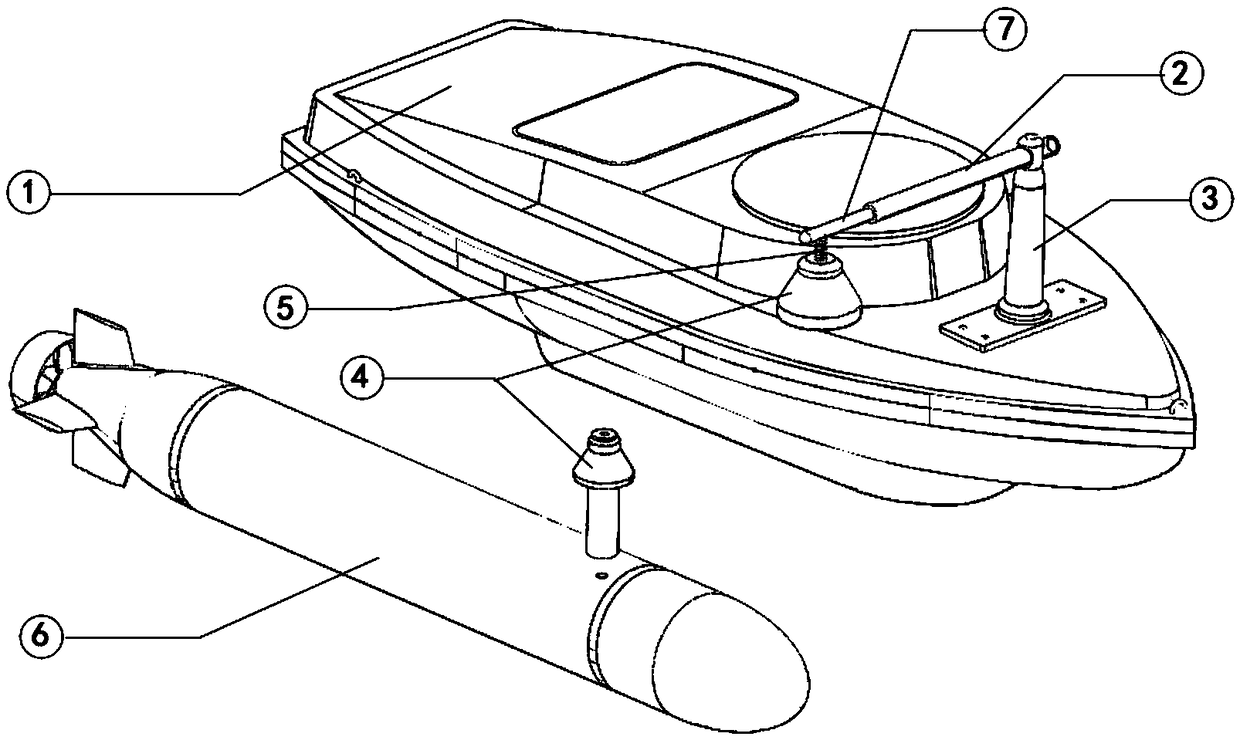

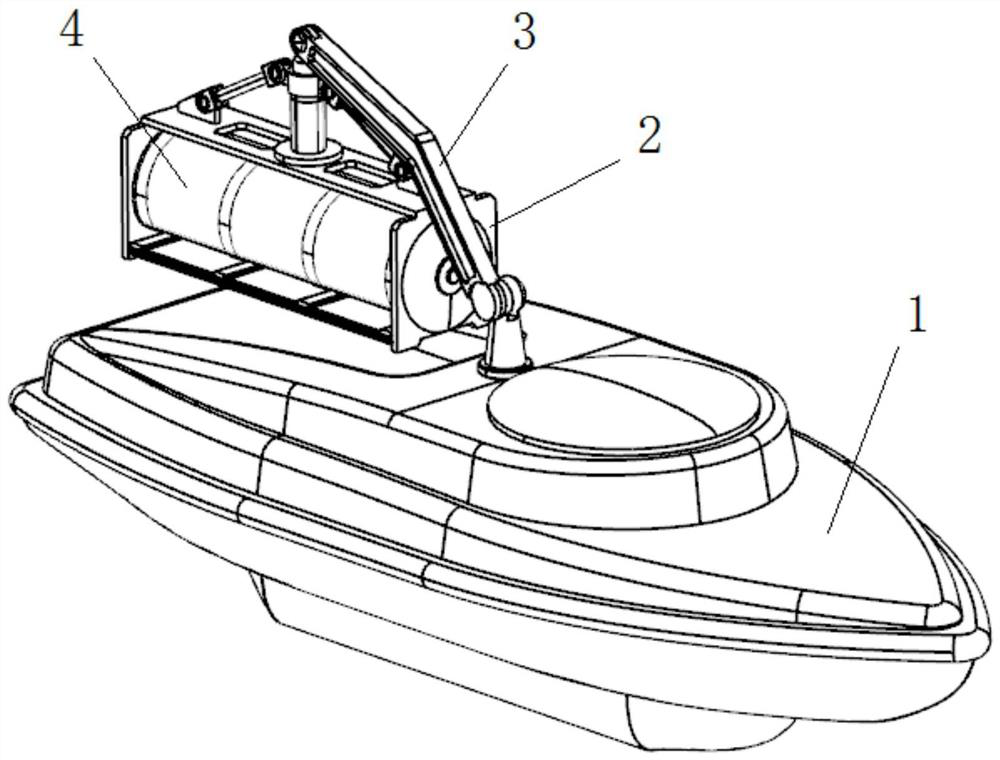

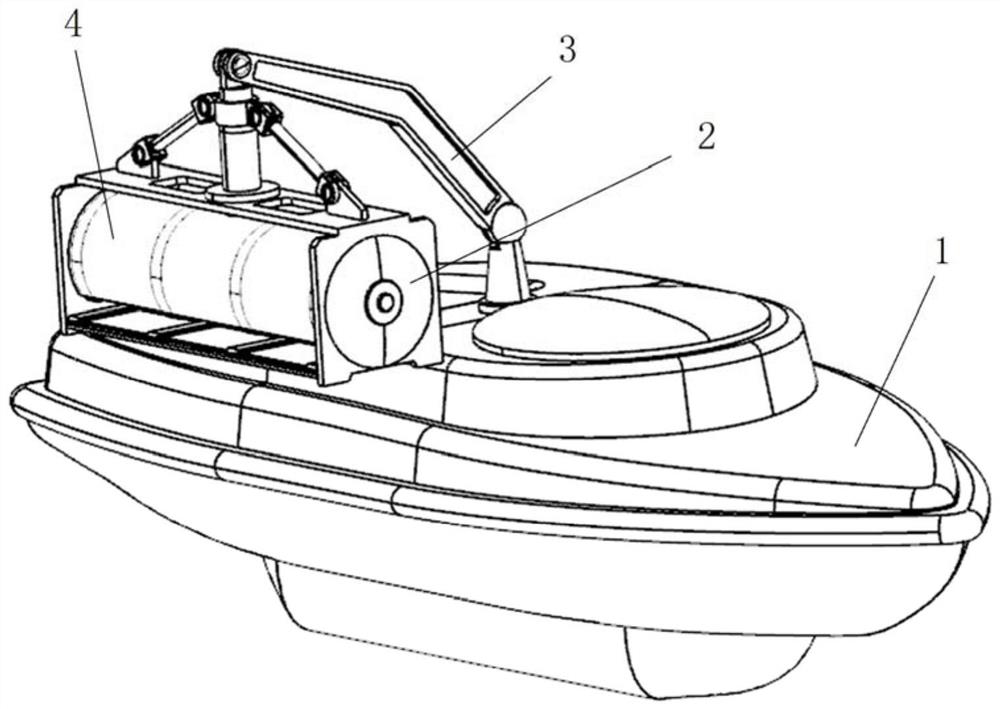

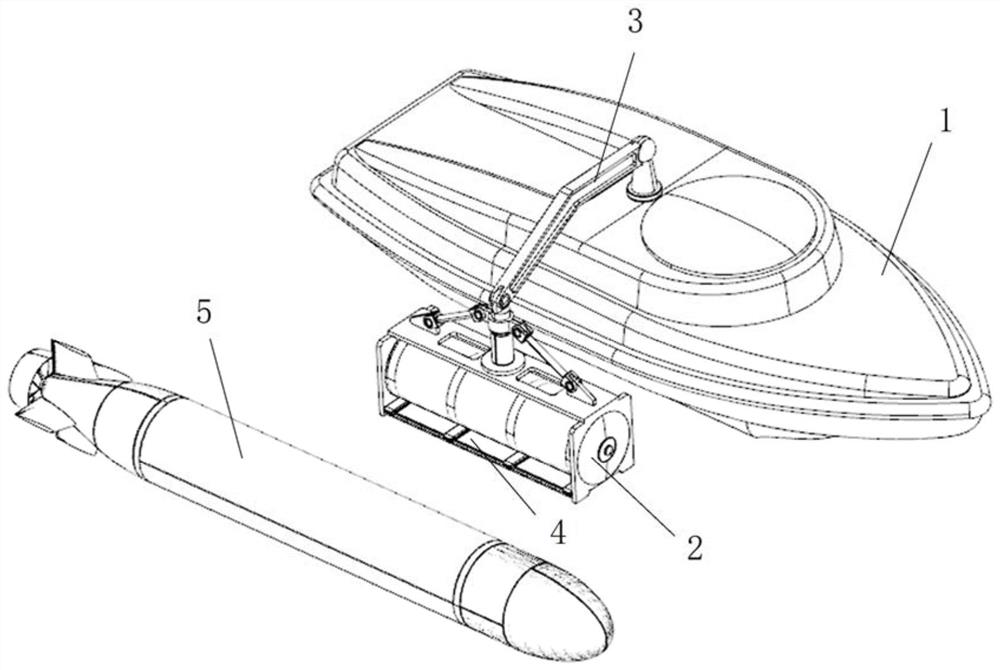

Recovering device and method for recovering UUV (underwater unmanned vehicle) on water surface of USV (unmanned surface vehicle) based on flexible arm

ActiveCN109911124ANo interface requirementPerformance is not affectedLifeboat handlingUnderwater vesselsRecovery methodControl unit

The invention relates to a recovering device for recovering a UUV (underwater unmanned vehicle) on the water surface of a USV (unmanned surface vehicle) based on a flexible arm. The recovering deviceis characterized by comprising a recovering control module, an oil path control unit, a hydraulic oil filling device, a flexible capturing belt and a suspending swing arm device; the recovering control module is arranged in a cabin of the USV; one end of the suspending swing arm device is arranged on a deck on the USV, and the other end of the suspending swing arm device is connected with the hydraulic oil filling device; a rolling wheel is arranged in the center position of the hydraulic oil filling device; the flexible capturing belt is curled on the rolling wheel; the oil path control unitis arranged on the hydraulic oil filling device; the recovering control module is sequentially connected with the oil path control unit, the hydraulic oil filling device and the flexible capturing belt; and the recovering control module is connected with the suspending swing arm device. The recovering device has the following beneficial effects: the recovering method provided by the invention adopts a flexible arm technology, is suitable for recovering the revolved body type UUV, does not have any interface requirement on the UUV, avoids influence on the overall performance of the UUV and hasconcise recovering step.

Owner:HOHAI UNIV

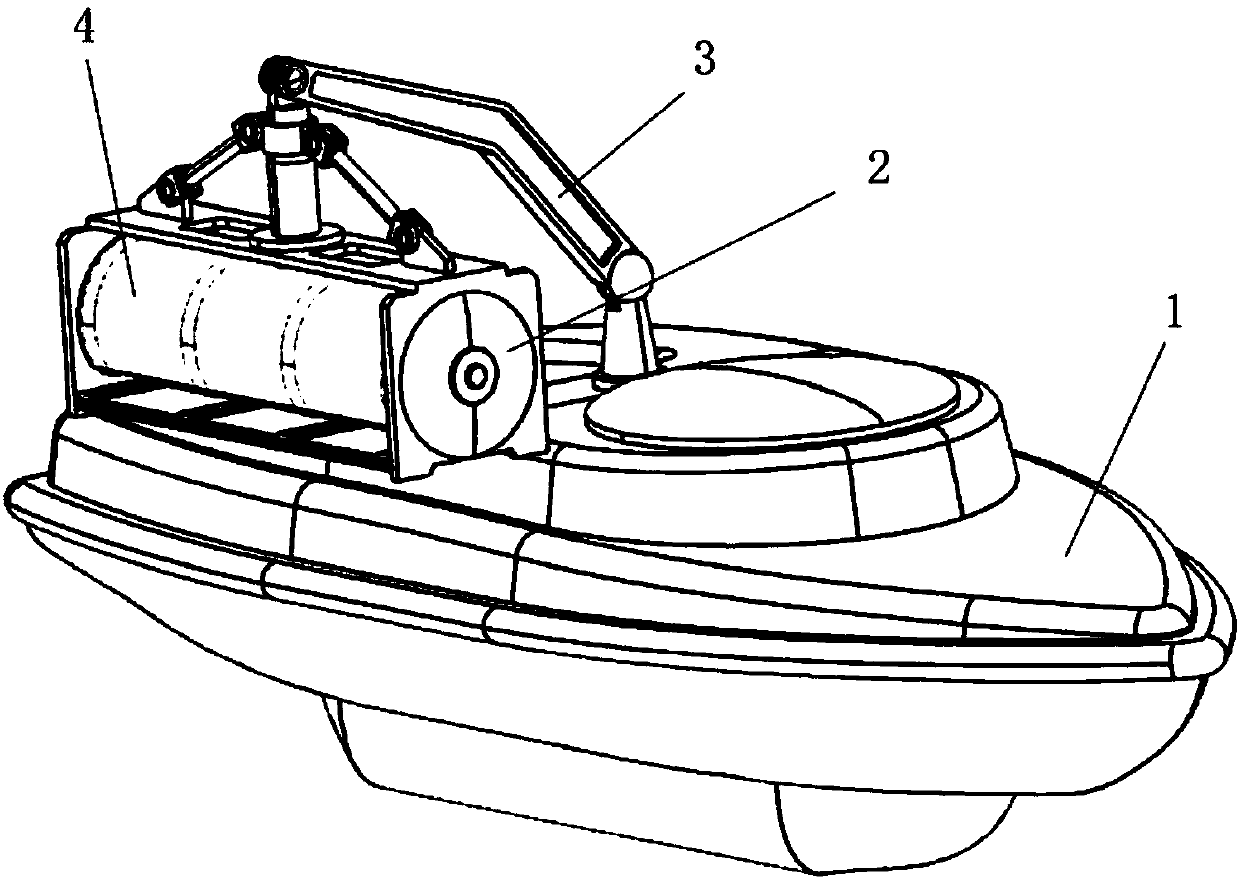

Water surface UUV (unmanned surface vessel) recycling device and method based on electromagnetic mushroom head engage switch

ActiveCN109398649APerformance is not affectedNo pollution in the processCargo handling apparatusPassenger handling apparatusButt jointShore station

The invention discloses a water surface UUV (unmanned surface vessel) recycling device based on an electromagnetic mushroom head engage switch. The water surface UUV recycling device comprises a recycling control module, a rotary swing arm device, a suspending telescopic rod, a hydraulic transmission device, a spring and an electromagnetic engage switch. The recycling control module is arranged ina cabin of a USV and can achieve remote communication with a shore station, a base of the rotary swing arm device is fixed to a deck of the USV through screws, the top of the rotary swing arm devicemakes the rotary swing arm device be fixed to one end of the suspending telescopic rod through a connection rod casing, one set of hydraulic transmission device used for controlling stretching and contracting of a cantilever telescopic rod is arranged in the suspending telescopic rod, the direction of the cantilever telescopic rod is regulated through self rotation of the rotary swing arm device,and the other end of the cantilever telescopic rod is welded to the electromagnetic engage switch through the spring. The invention further discloses a water surface UUV recycling method. The water surface UUV recycling device and method have the beneficial effects that the device and method can realize simple, convenient and firm butt joint, and the recycling efficiency and the success rate are greatly improved.

Owner:HOHAI UNIV

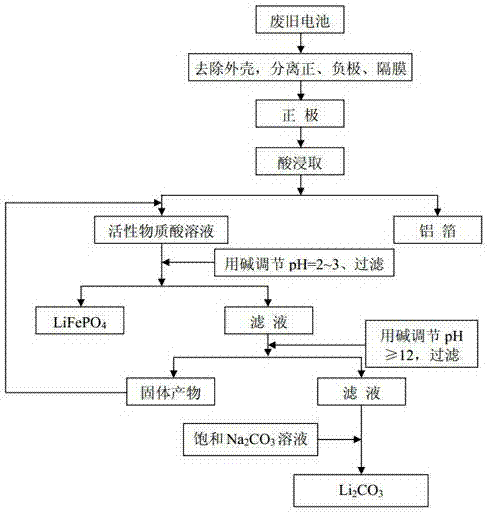

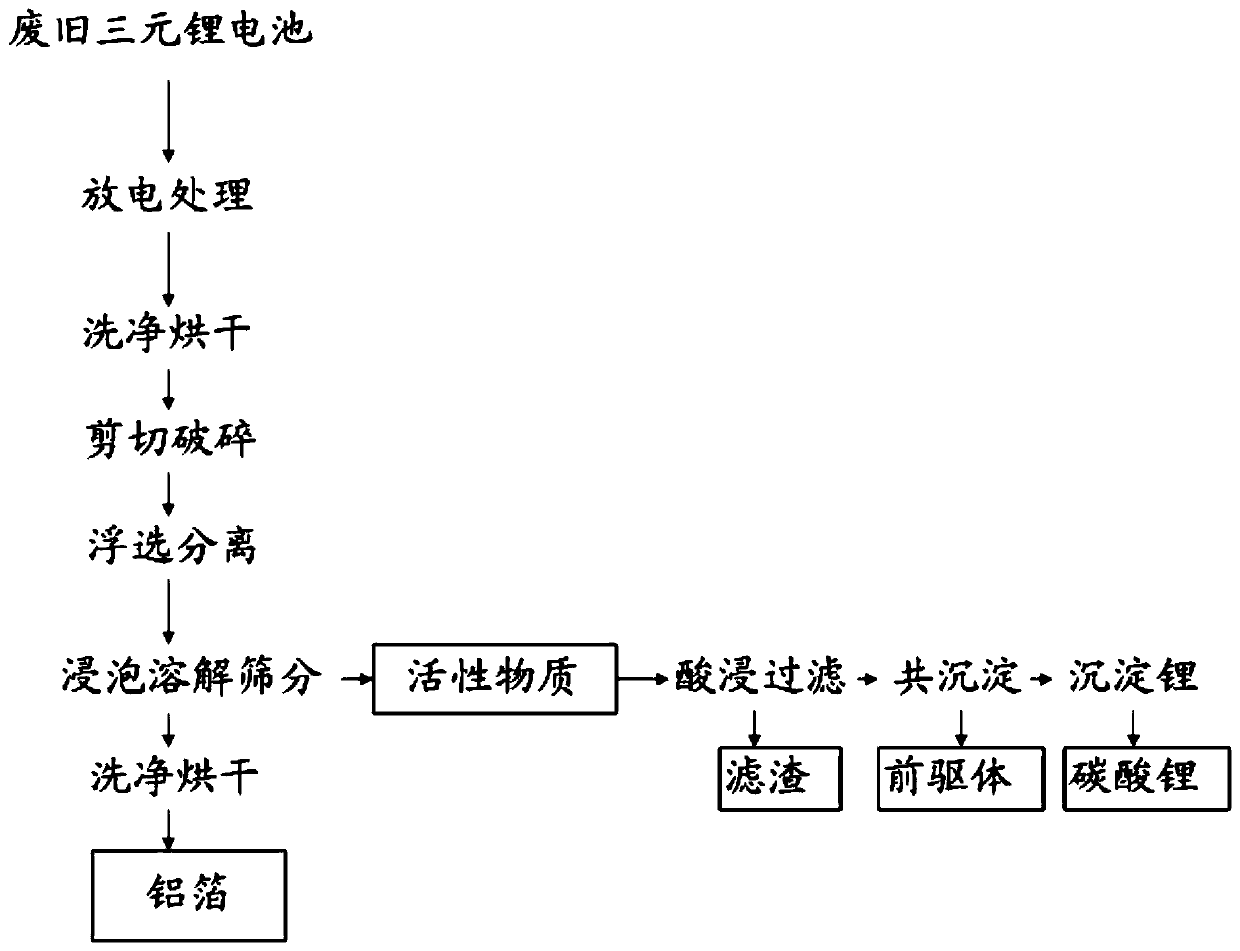

Recovery and recycling process for positive electrode material of waste ternary lithium battery

PendingCN111600089AEffective dissolutionEasy to degradePositive electrodesWaste accumulators reclaimingEngineeringProcess engineering

The invention provides a recovery and recycling process for a positive electrode material of a waste ternary lithium battery. The positive plate treatment liquid used in the invention has extremely low toxicity on material components, can effectively dissolve a binder in the separation process to separate out active substances, and has extremely high efficiency, and the dissolving liquid is easy to degrade and is very environment-friendly. Furthermore, in the subsequent recovery process, an organic extracting agent is mostly used for extracting and recovering valuable metals at present, the used extracting agent seriously pollutes the environment, and the extraction process is very complex at the same time. According to the invention, a coprecipitation method is used, the use of the extracting agent is avoided, the recovery steps are simplified by directly synthesizing a precursor, and energy conservation and environmental protection are achieved.

Owner:NINGBO UNIV

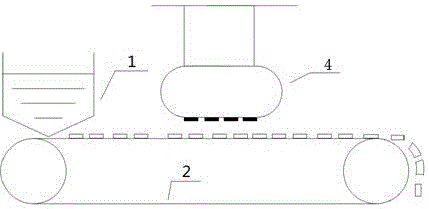

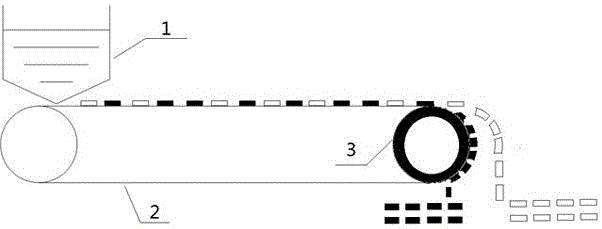

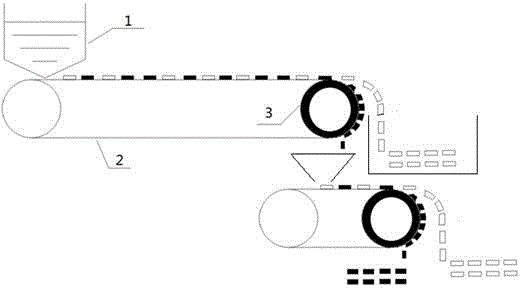

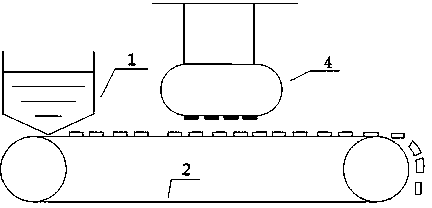

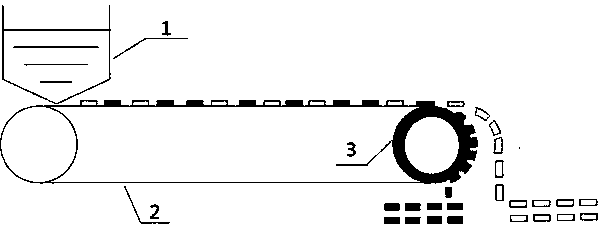

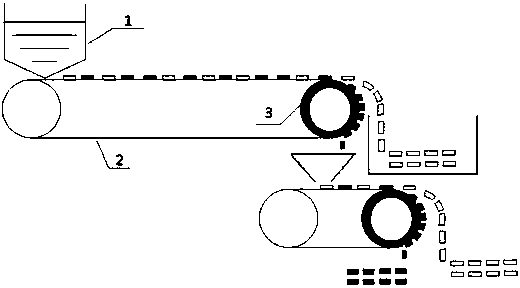

Method for separating positive electrode, negative electrode and diaphragm of LiFePO4 battery

ActiveCN103474720AAvoid harmHigh purityWaste accumulators reclaimingBattery recyclingElectrical batteryOrganosolv

The invention relates to a method for separating a positive electrode, a negative electrode and a diaphragm of a LiFePO4 battery. The method comprises the following steps: a, mechanically crushing a core (comprising a mixture of the positive electrode, the negative electrode and the diaphragm) of a shelled LiFePO4 battery into fragments with the sizes of 1 cm<2> to 100 cm<2>; b, uniformly feeding the fragments to a conveying belt by using a feeding machine, wherein the fragments are flatly paved on the conveying belt and move forwards at a constant speed, and a magnet is arranged above the conveying belt or a magnetic roller is adopted to separate the magnetic positive electrode material from negative electrode material and the diaphragm; and c, soaking the negative electrode material and the diaphragm material, which are obtained after the positive electrode material is separated, into water, collecting the diaphragm material which floats on the upper layer, and refloating and collecting the negative positive electrode material which is settled at the bottom so as to separate the negative electrode from the diaphragm. With the method, the positive electrodes, the negative electrodes and the diaphragms of the LiFePO4 batteries can be separated conveniently, quickly and efficiently on a large scale, and possible environmental harm caused by organic solvents, high-temperature heating method and the like is avoided.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

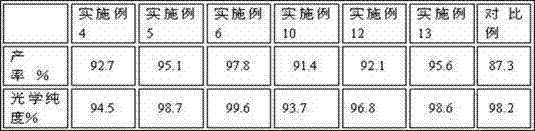

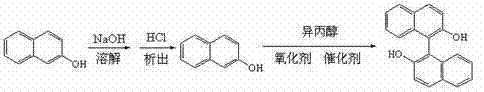

Chiral catalyst in binaphthol synthesis technology

ActiveCN103480418AHigh feasibilityHigh optical purityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsImpurityCoordination complex

A chiral catalyst in a binaphthol synthesis technology is a 1,2-cyclohexanediamino-2-(3-hydroxy-2-naphthalenone)Schiff base-ferric iron complex, and the 1,2-cyclohexanediamino-2-(3-hydroxy-2-naphthalenone)Schiff base is generated through reacting (1R,2R) or (1S,2S)1,2-cyclohexanediamine with 3-hydroxy-2-naphthalenone. The structural formula of the chiral catalyst is shown in the specification. Cheap ferric iron same with the center ligand of the catalyst is adopted as an oxidant to carry out a chiral catalytic reaction, and the adoption metal ions as an oxidant can guarantee the high conversion rate of a product; the catalyst does not react with the oxidant to form impurities in a catalyst and oxidant recovery process, so a recovery step is simplified, and the recovery feasibility of the catalyst is improved; and the recycle of the catalyst and the oxidant can guarantee a high optical purity of the product, a high conversation rate and a high optical purity can be realized on the basis of a low cost, the pressure to the environmental protection is reduced, and the green chemistry is realized.

Owner:宿迁思睿屹新材料股份有限公司

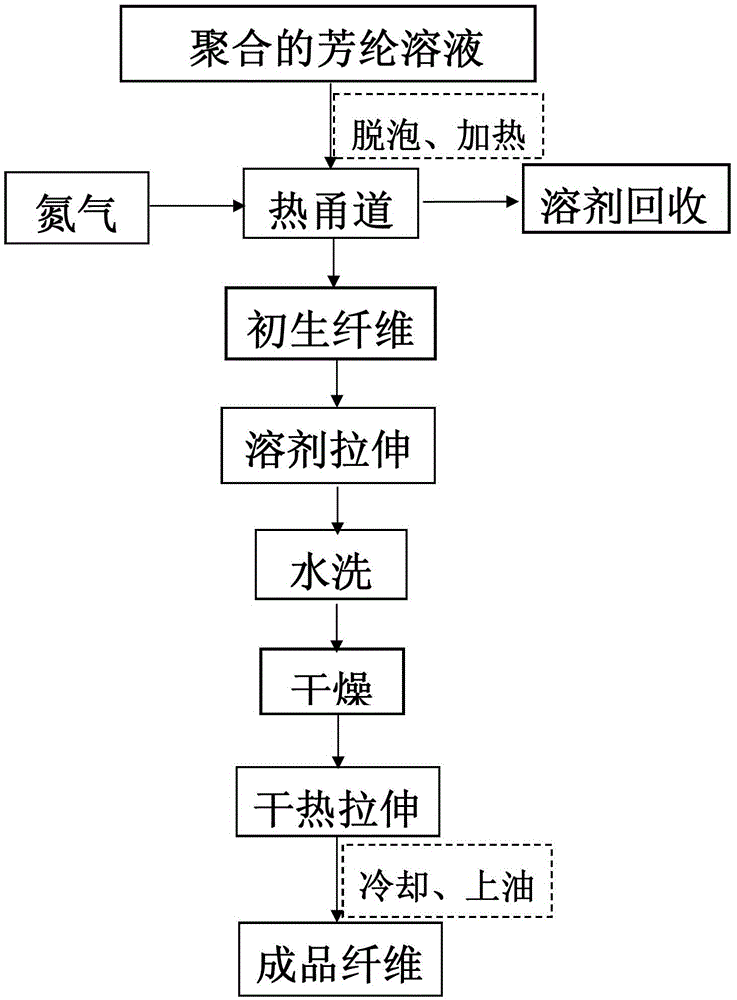

A kind of preparation method of meta-aramid fiber

ActiveCN103233292BLow ion contentSimplify recycling stepsArtificial filament recoveryTextile/flexible product manufactureIon contentHydrogen chloride

The invention relates to a method for preparing meta-position aramid fibers. The method is characterized by comprising the following steps: specially preparing a spinning solution of three components such as poly(m-phenyleneisophthalamide), hydrogen chloride and N, N-dimethylacetamide through adopting polymerization; deaerating the solution, then heating the solution, extruding the solution through a spinneret plate to enter a spinning hot channel, and removing solvents such as the N, N-dimethylacetamide and the hydrogen chloride through the hot channel so as to obtain nascent fibers; and stretching the nascent fibers through the solvent, washing to further removing the hydrogen chloride and the solvent in the nascent fibers, then drying, dry heating and stretching, cooling and oiling to obtain the finished fibers. The poly(m-phenyleneisophthalamide) spinning solution does not contain salt, and the deionized water and the solvent instead of salt are used in a whole fiber production process, so that the finally prepared meta-position aramid fiber products are low in ion content and fiber ash content; and solvent recovery steps are simplified, and energy sources are greatly saved.

Owner:X FIPER NEW MATERIAL CO LTD

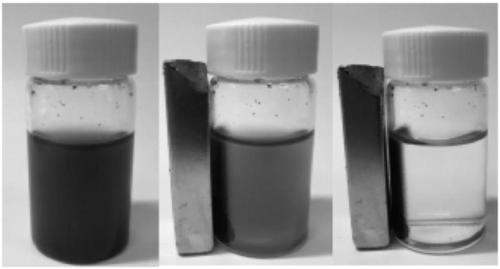

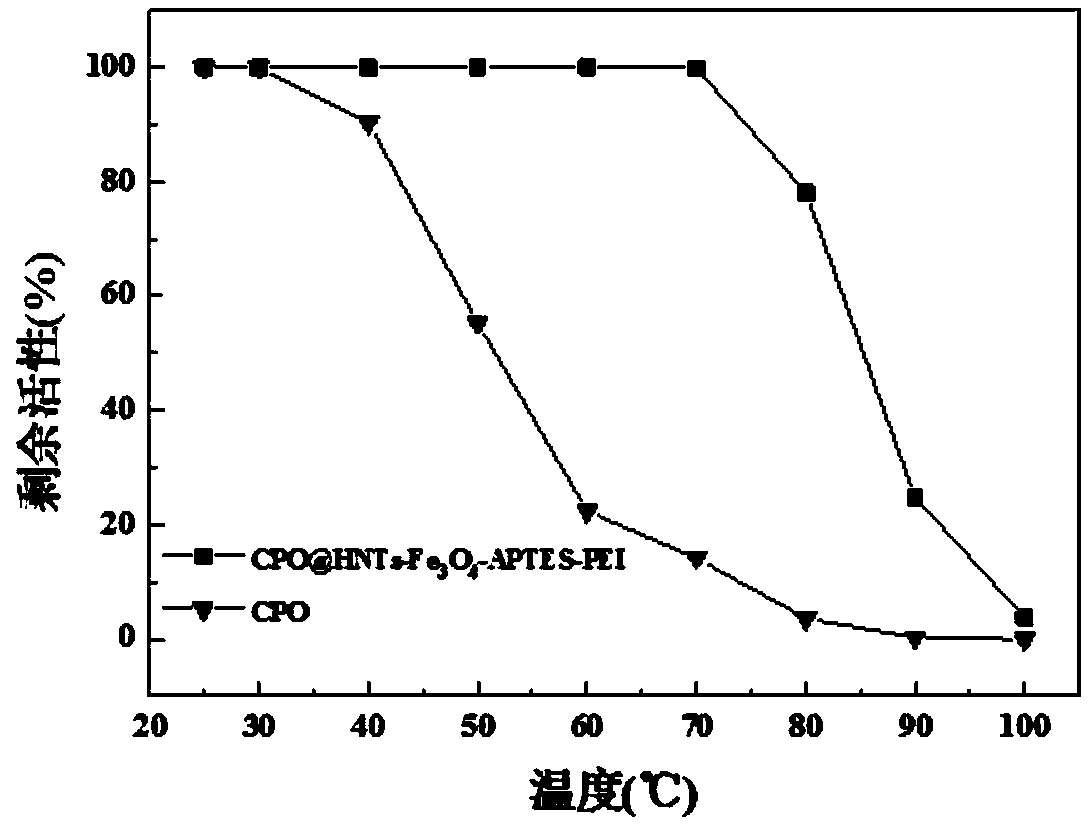

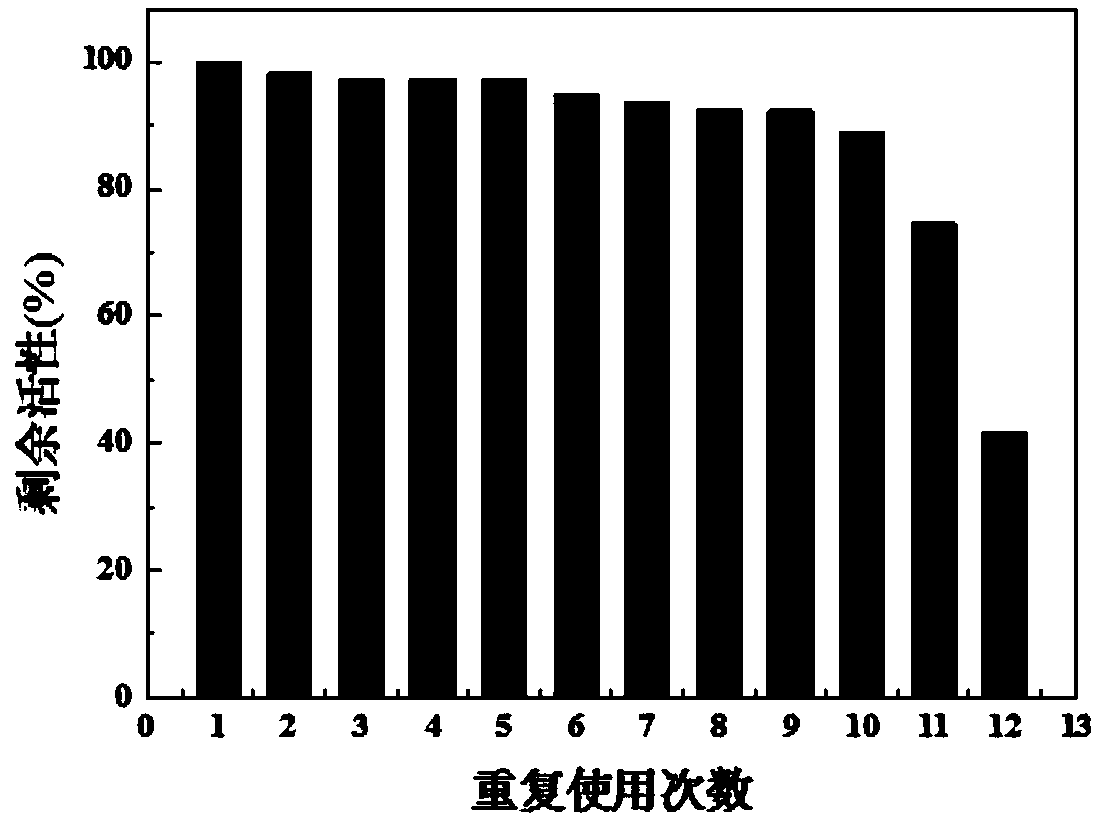

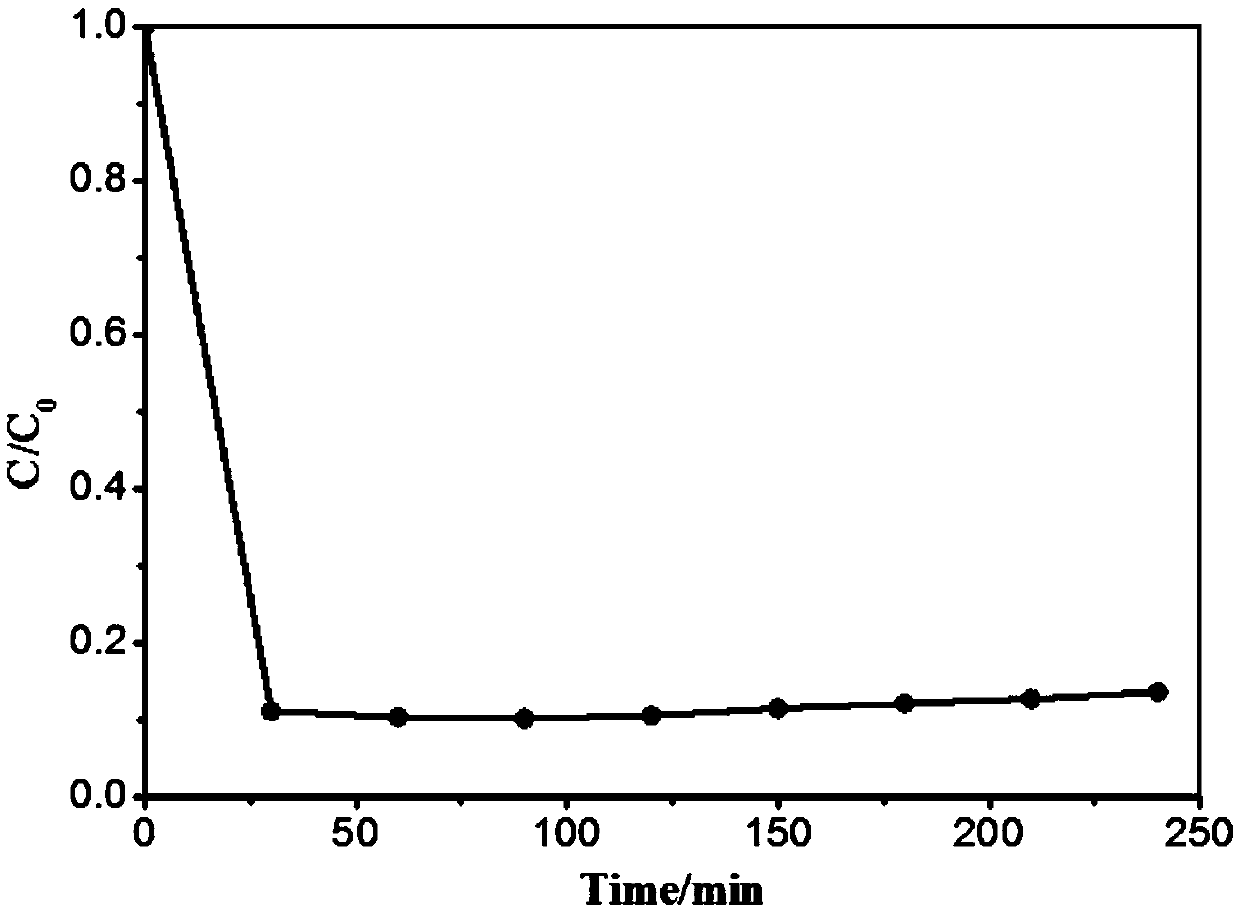

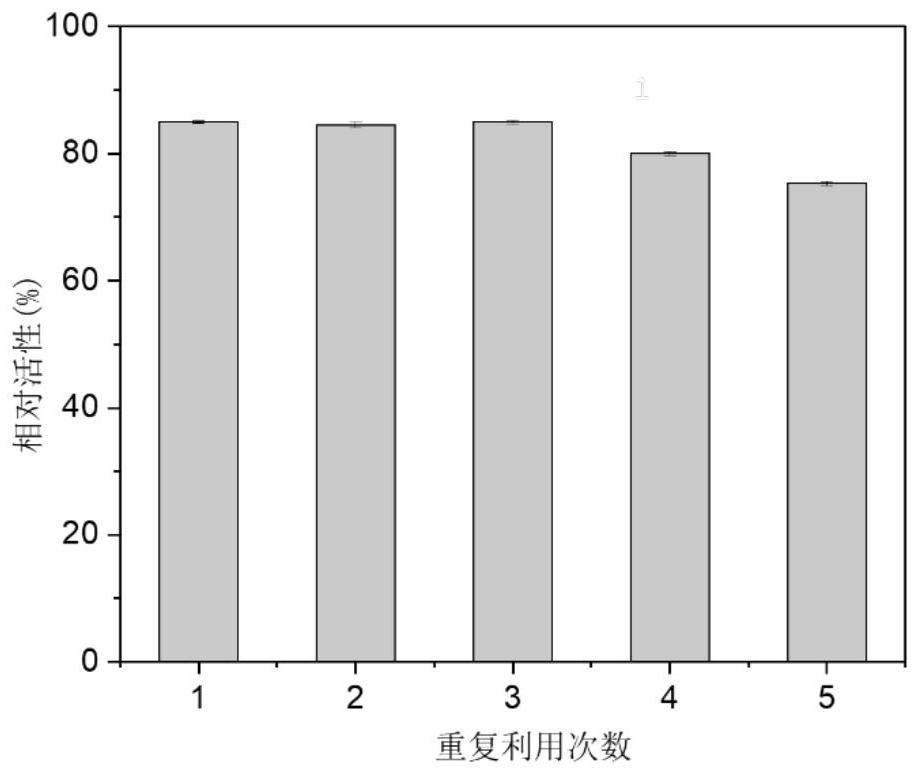

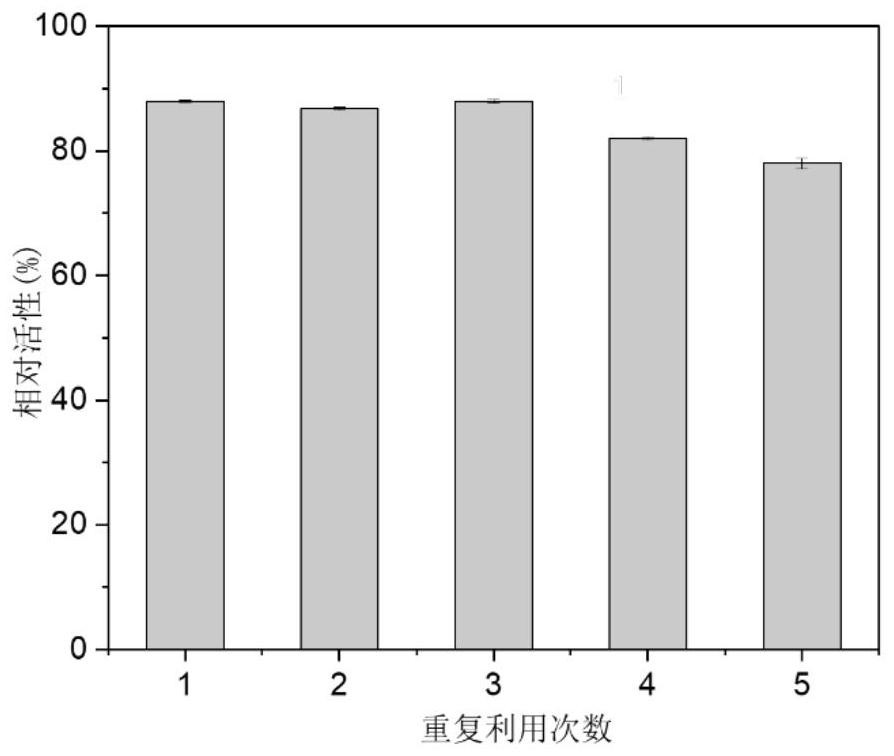

Reactor prepared in mode of simultaneously fixing chloroperoxidase to inner and outer walls of surface modified magnetic halloysite nanotubes and application

ActiveCN109280660AIncrease the number of amino groupsIncrease loading capacityOxidoreductasesOn/in inorganic carrierHalloysiteHeat stability

The invention discloses a reactor prepared in a mode of simultaneously fixing chloroperoxidase to the inner and outer walls of surface modified magnetic halloysite nanotubes and application. A methodcomprises the steps that magnetic materials, namely ferroferric oxide, are modified on the halloysite nanotubes firstly; then 3-aminopropyltriethoxysilane and polyethyleneimine are sequentially modified on the surfaces of the magnetic halloysite nanotubes, so that the inner and outer walls of the modified magnetic halloysite nanotubes are both positively charged; and finally, the chloroperoxidaseis fixed to the interiors of the tubes through physical absorption and fixed to the outer walls of the tubes through covalent binding, and the enzyme reactor is obtained. On the basis of simultaneousfixing of the inner and outer walls, the immobilization amount of the chloroperoxidase is increased, the obtained enzyme reactor is easy, convenient and fast to recycle, 92.20% of catalytic activity can be kept after reuse for nine times, heat stability is better than heat stability of free enzymes at 70-80 DEG C, toleration is good in organic solvents such as DMF, methanol and acetonitrile, the degradation efficiency for degrading rifaximin is high, and when the content of the rifaximin is within 50 [mu]g / mL, the degradation efficiency can reach 90% or above.

Owner:SHAANXI NORMAL UNIV

A composite extraction system and extraction method for extracting lithium from lithium-containing brine

The invention discloses a composite extraction system and an extraction method for extracting lithium from lithium-containing brine. The composite extraction system is loaded with 2.5-10.4g / L of Fe(III), including 10%-60% of extractant A and 10%-30% of extractant B, and the balance is diluent, wherein the extraction The agent A is a neutral phosphine extractant and / or an amide extractant, the extractant B is an acidic phosphine extractant, and the percentage is the volume percentage in the composite extraction system. The composite extraction system of the invention can effectively extract lithium from lithium-containing brine, especially can effectively strip lithium at a pH of 1.0-1.8, avoid the corrosiveness of high-acid stripping to equipment, and lithium in stripping liquid easy to recycle.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

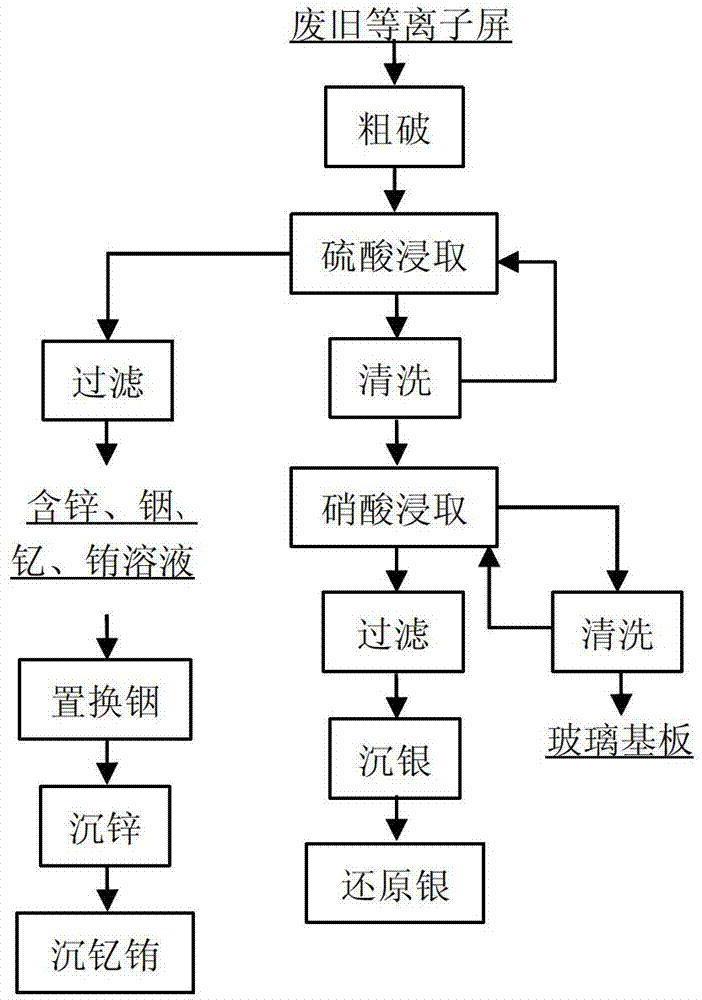

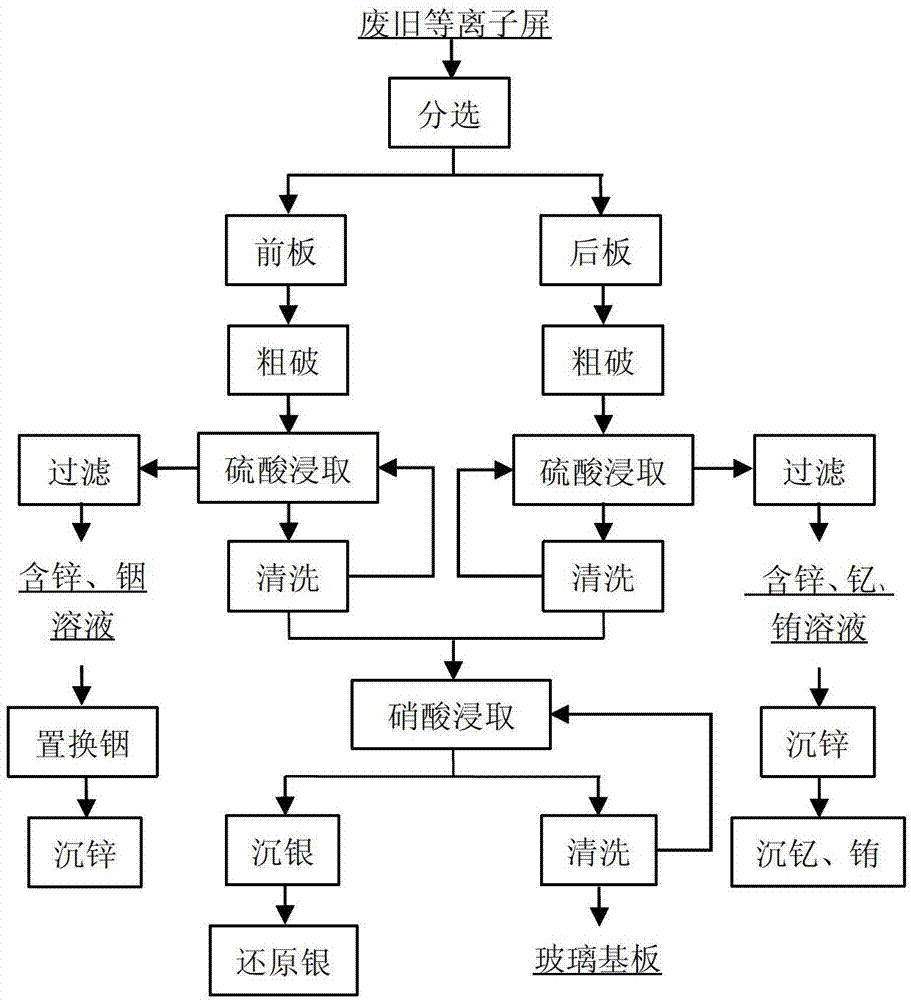

Comprehensive recycling method of waste plasma screen

ActiveCN102925696AOvercome the problem of easy bonding when exposed to waterSolve the problem of easy bonding when exposed to waterProcess efficiency improvementGranularityToxic industrial waste

The invention discloses a comprehensive low-energy consumption recycling method of a waste plasma screen and belongs to the field of industrial waste regeneration. The method comprises that a), the waste plasma screen is roughed, so that the maximum range between any two points of the waste plasma screen ranges between 5cm and 30cm; b), the roughed waste plasma screen is added into a salpeter solution for leaching, during leaching, ultrasonic wave activating treatment and stirring are conducted; and c), silver is recycled from an obtained solution which is subjected to nitrate leaching. According to the method, the step that the plasma screen is required to fine grinding is reduced, the energy consumption is reduced, the leaching time is reduced, the efficiency is improved, and the problems that for a long time, technical workers in the field hold a technical bias that the granularity has to be reduced as possible in order to improving the leaching efficiency, and glass is easy to bond when encountering water are solved. The method is low in energy consumption, high in efficiency, capable of preparing silver with the purity of more than 99.9% and being processed in large scales, and suitable for being popularized and applied in the field.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

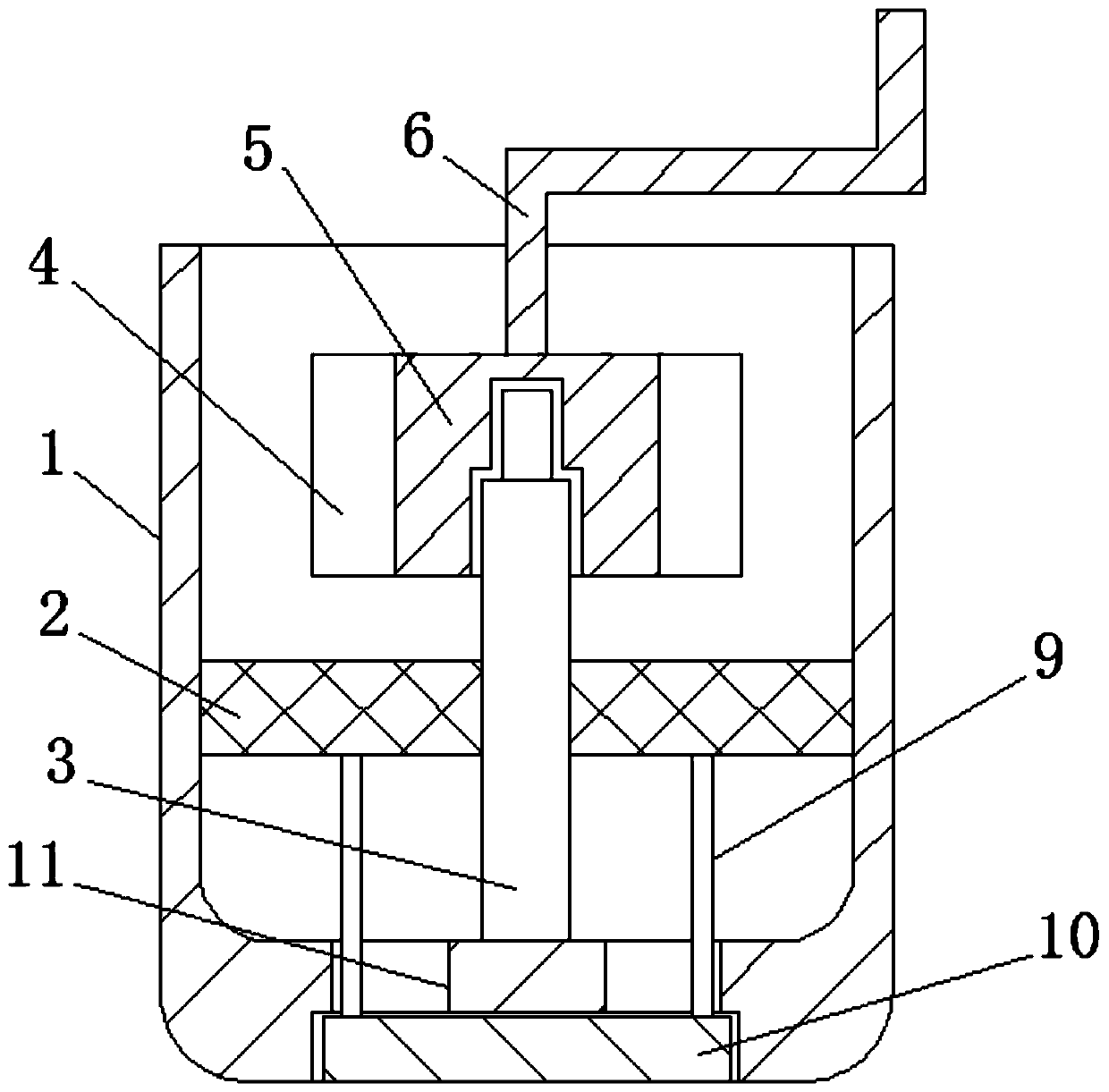

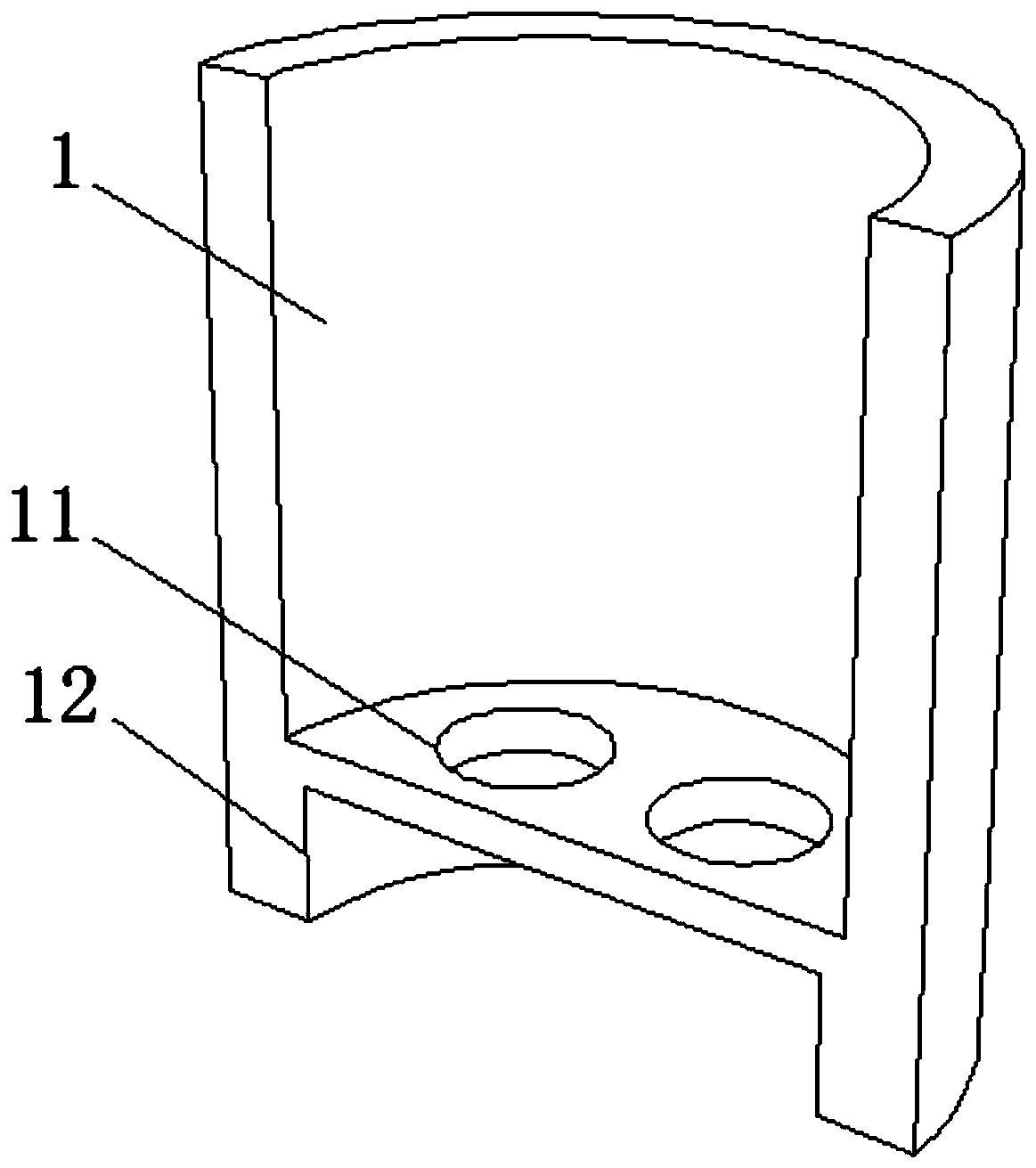

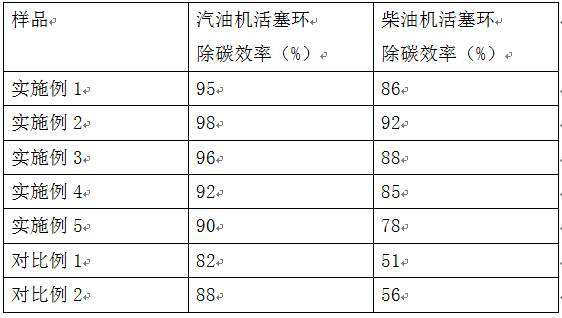

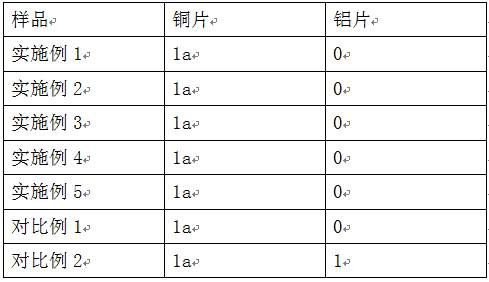

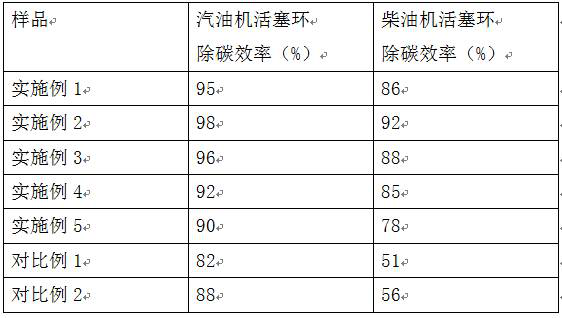

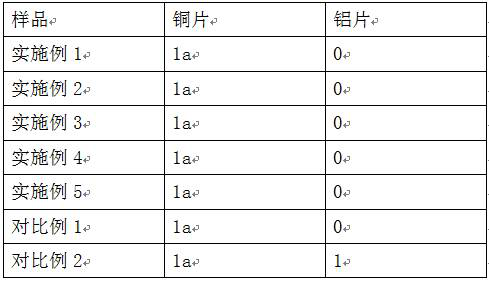

Efficient organic piston ring carbon removal repairing agent

ActiveCN111925844AImprove securityStrong wrappingLiquid carbonaceous fuelsFuel additivesCombustion chamberActive agent

The invention provides an organic piston ring carbon removal repairing agent, which is characterized by comprising the following components in parts by mass: 50-80 parts of a carbon deposition dissolving agent, 5-20 parts of a purification dispersing agent, 1-5 parts of an ester type lubricating tackifier, 1-10 parts of a solvent type surfactant, 1-2 parts of an oil stain disintegration accelerantand 0.1-1 part of an auxiliary agent. The organic piston ring carbon removal repairing agent can effectively remove combustion chamber deposited carbon in a cylinder cover, a piston top and a pistonring groove, clean and release a piston ring, recover the elasticity and cylinder pressure of the piston ring, and recover the stuck piston ring. The problems of knocking, poor heat dissipation, insufficient cylinder pressure, high engine oil consumption and the like are solved.

Owner:杭州维客泰美品牌管理有限公司

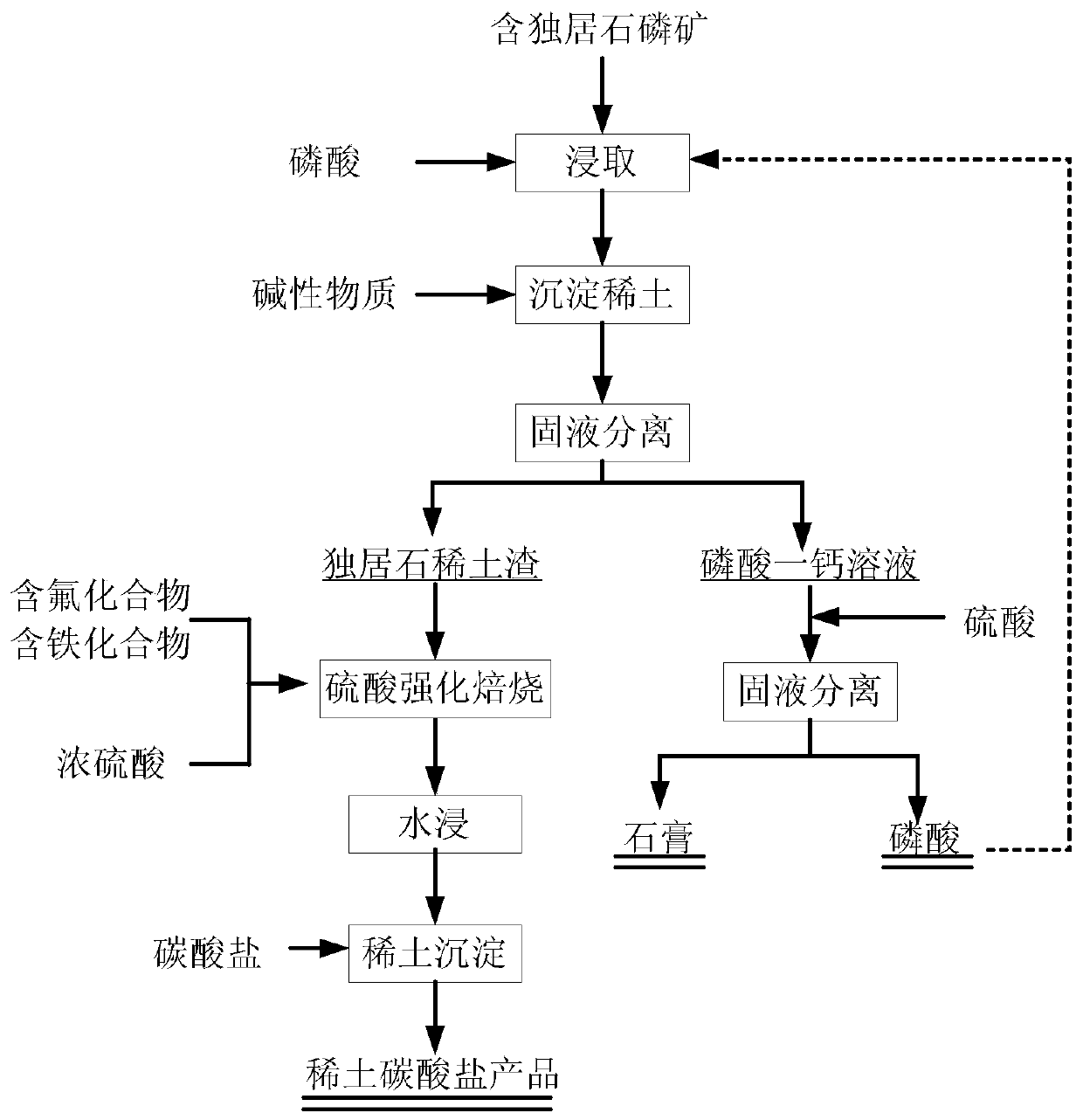

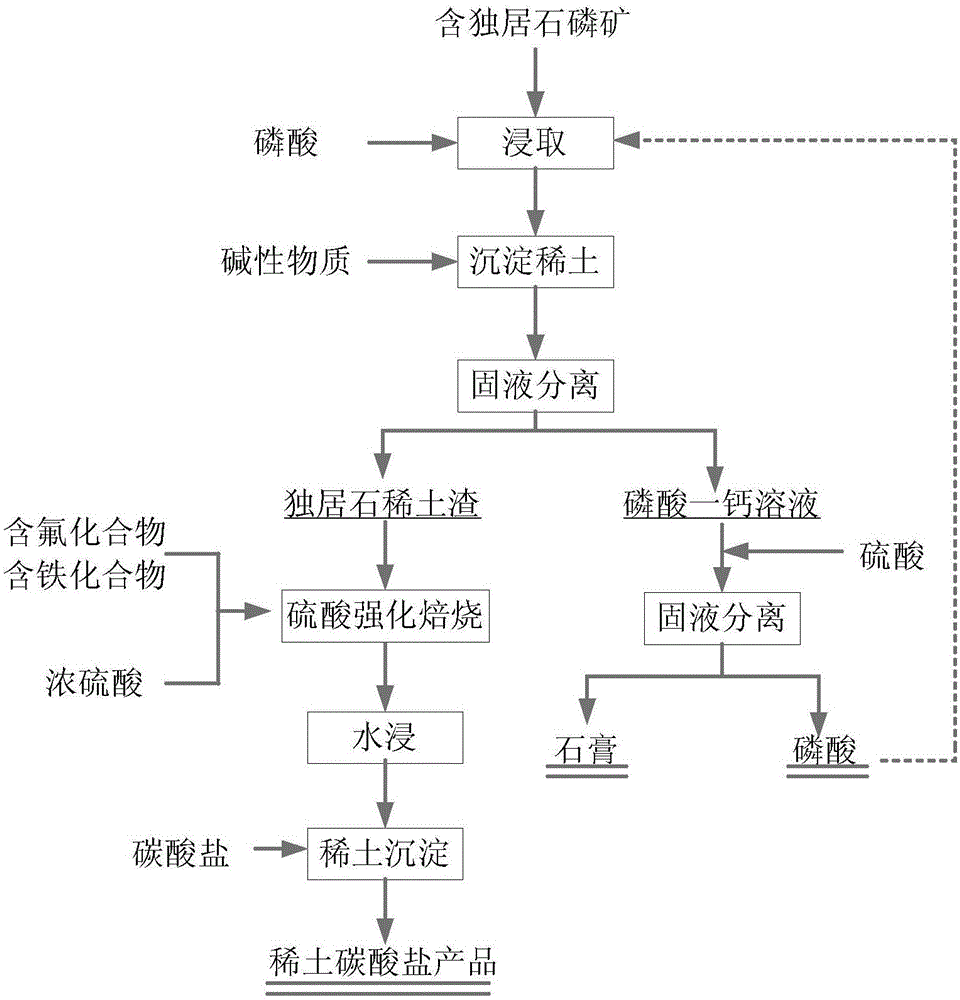

Method for recovering phosphorus and rare earth from rare earth-containing phosphate rock

ActiveCN105886798BHigh recovery ratePromote leachingProcess efficiency improvementPhosphorus compoundsSolubilityCalcium biphosphate

The invention discloses a method for recovering phosphorus and rare earth from phosphate rock containing rare earth. The method comprises the following steps: using a mixed acid solution to leach rare earth-containing phosphate rock, filtering to obtain a monocalcium phosphate solution and a phosphate-containing rare earth slag, the main body of the mixed acid solution is phosphoric acid, and the mixed acid solution also contains hydrochloric acid and / or nitric acid; recovering the monocalcium phosphate Phosphorus in calcium solution, and recovery of rare earth in phosphate-containing rare earth slag. The method uses a mixed acid solution to leach rare earth-containing phosphate rock, so that the phosphorus in the phosphate rock forms monocalcium phosphate with high solubility, and at the same time, the rare earth is precipitated and enriched in the slag in the form of rare earth phosphate by adjusting the acidity of the leaching process. The rare earth-containing phosphate rock also contains monazite, which enriches monazite and rare earth phosphate into the slag, and then separates phosphorus and rare earth, simplifies the recovery steps, improves the recovery rate of rare earth, and realizes the purpose of comprehensive recovery of rare earth at low cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

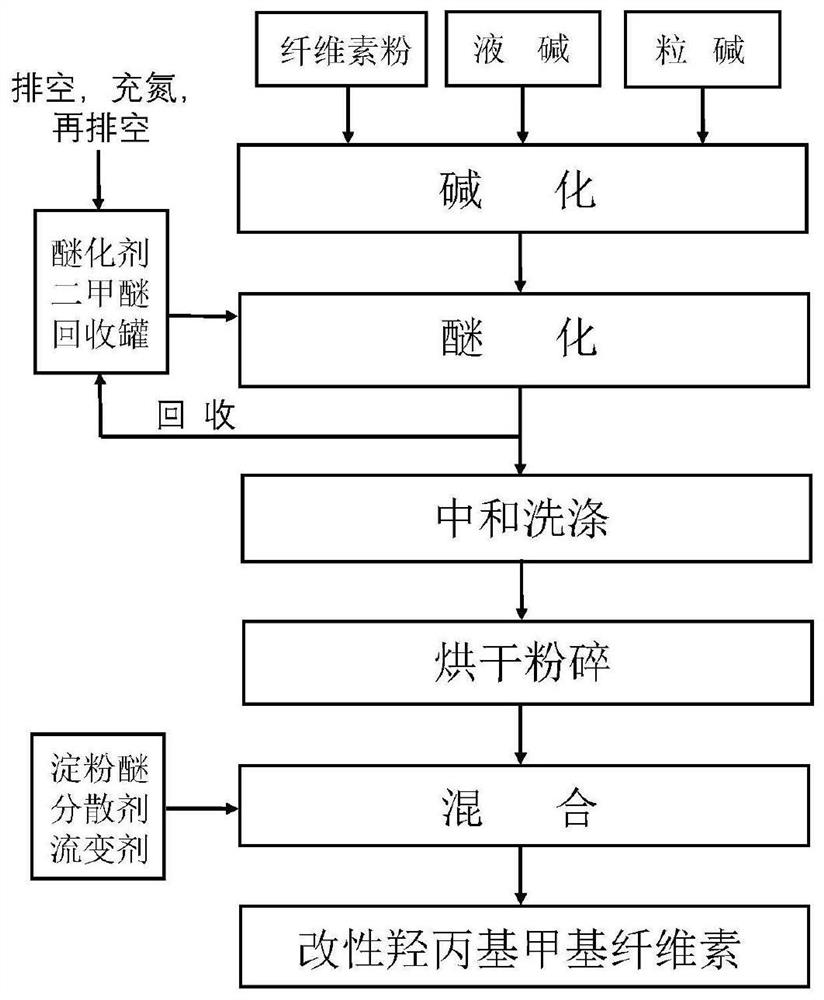

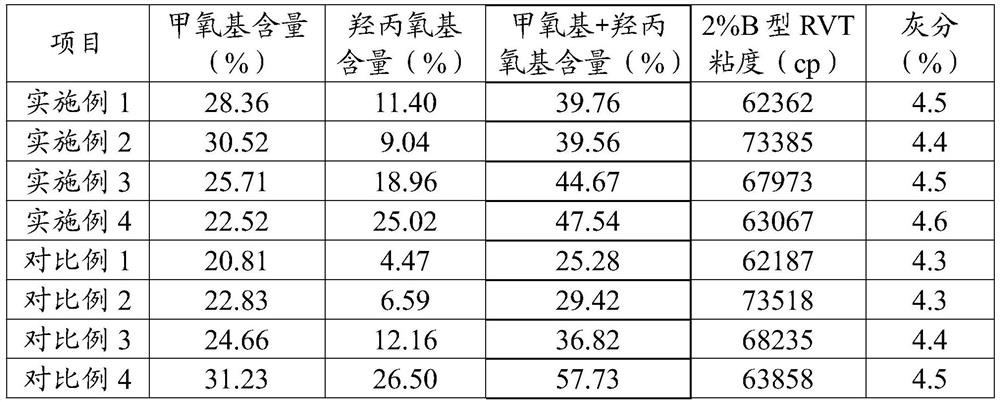

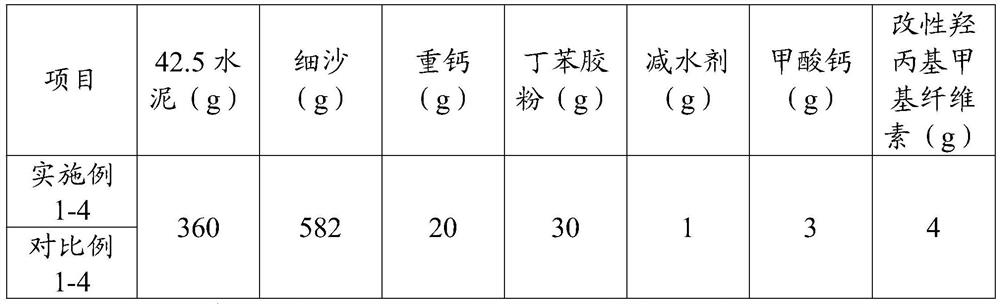

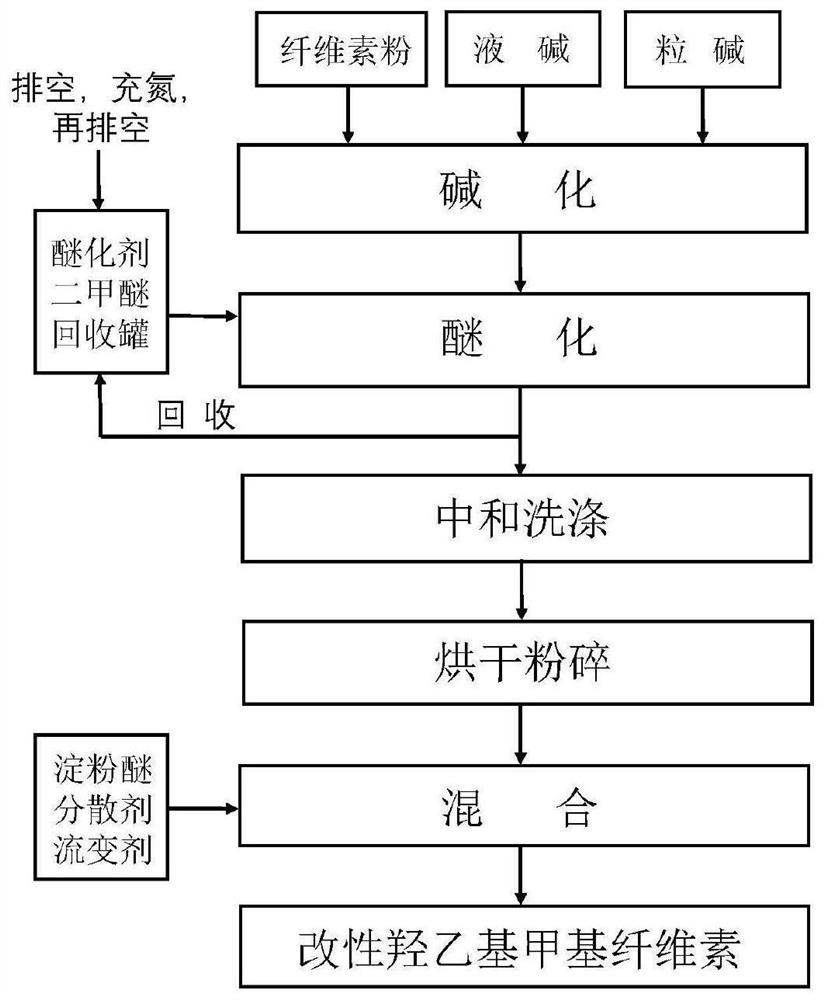

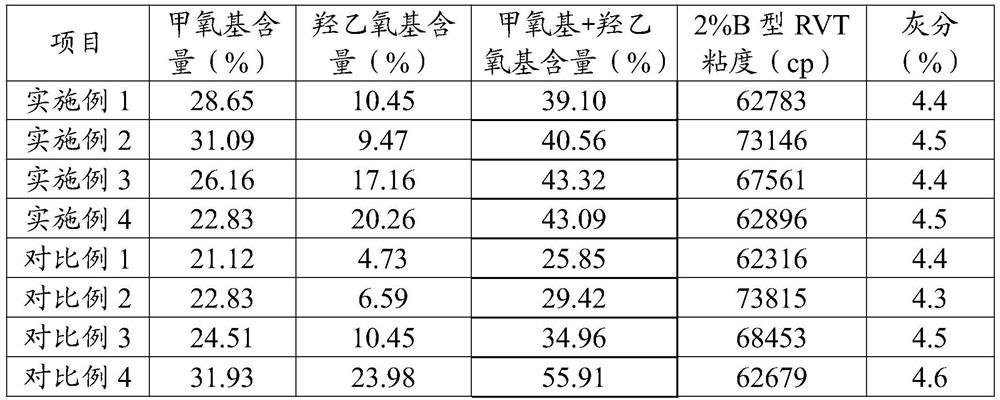

Modified hydroxyethyl methyl cellulose for enhanced ceramic tile adhesive and preparation method and application thereof

ActiveCN111748299AImprove product qualityQuality improvementStarch derivtive adhesivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses modified hydroxyethyl methyl cellulose for an enhanced ceramic tile adhesive. The modified hydroxyethyl methyl cellulose is prepared from the following raw materials in percentage by mass: 54%-94% of hydroxyethyl methyl cellulose, 5%-40% of starch ether, 0.5%-3% of a dispersing agent and 0.5%-3% of a rheological agent, wherein the hydroxyethyl methyl cellulose is prepared from cellulose powder, caustic soda granules, caustic soda liquid, chloromethane and ethylene oxide. The preparation method comprises the following steps: (1) weighing the raw materials, (2) mixing cellulose powder, caustic soda particles, liquid caustic soda, chloromethane and ethylene oxide, carrying out etherification reaction, and then sequentially carrying out neutralization, washing, centrifugation, drying and crushing to obtain hydroxyethyl methyl cellulose, and (3) mixing and stirring hydroxyethyl methyl cellulose, starch ether, a dispersing agent and a rheological agent to obtain the adhesive. The obtained product is stable in quality, has the function of improving the tensile bonding strength of the ceramic tile adhesive, is applied to modern ceramic tiles with large sizes and large masses, and can remarkably improve the use safety of the ceramic tiles.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

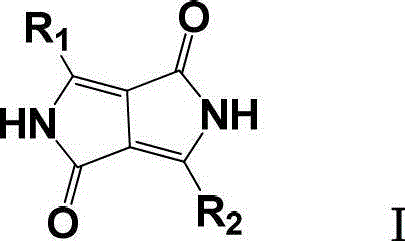

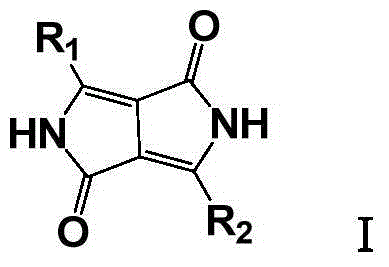

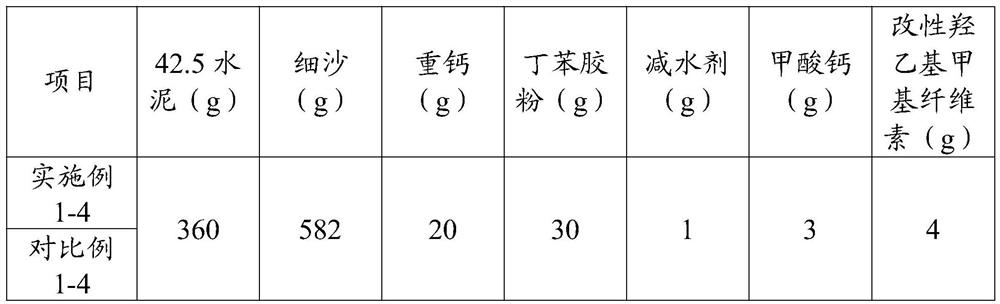

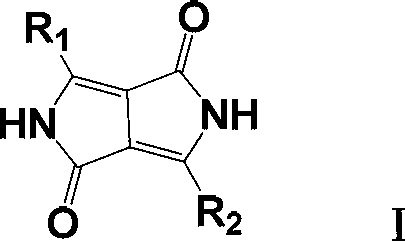

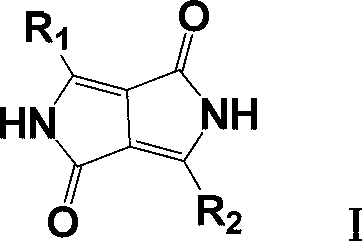

Improved method for preparing pyrrolopyrrole-1,4-diketone derivative

ActiveCN103012409ASimplify recycling stepsReduce manufacturing costOrganic chemistryAzo dyesPotassiumSuccinic acid

The invention relates to a method for preparing a pyrrolopyrrole-1,4-diketone derivative (the pyrrolopyrrole-1,4-diketone derivative can be used for preparing organic pigments). The method includes the main step: a target object is obtained through the reaction of succinic acid dialkyl ester and a nitrile compound at a temperature of 60 DEG C-140 DEG C in a sodium tert-pentoxide or potassium / tert-amyl alcohol medium. The method is characterized in that firstly, the adopted succinic acid dialkyl ester is succinic acid di-tert amyl ester; and secondly, after the reaction of succinic acid ditertiary amyl ester and the nitrile compound is stopped, the obtained mixture is heated and dried at the vacuum degree of 1-2 mmHg, the escaped tert-amyl alcohol is recovered at the same time, after heating and drying, the mixture heated and dried is transferred to a hydrolyzing reactor and diluted by carbinol / water, the generated sodium hydroxide is neutralized through inorganic acid, and the target object is obtained through liquid / solid separation. According to the invention, the steps for tert-amyl alcohol recovery are simplified, further, the cost in preparing the pyrrolopyrrole-1,4-diketone derivative is reduced.

Owner:辽宁鸿港化工有限公司 +2

Preparation method for Fe and Cu bi-metal loading mesoporous carbon and alumina composite ceramic membrane material, and application of ceramic membrane material

InactiveCN107661698APromote degradationPlay a role in separationMembranesSemi-permeable membranesWater bathsComposite ceramic

The invention relates to a preparation method for a Fe and Cu bi-metal loading mesoporous carbon and alumina composite ceramic membrane material, and the application of the ceramic membrane material.An aluminium oxide hollow ceramic tube is dried in a drying oven; the Fe(NO3)3.9H2O and the Cu(NO3)2.3H2O of a mesoporous carbon precursor are added to be dissolved in absolute ethyl alcohol, mixtureis heated in a water bath and dripped into the ethanol solution of the mesoporous carbon precursor; the mixture is poured into watch glass and is evaporated at a room temperature to obtain a thick Feand Cu mesoporous material; two ends of a pre-prepared aluminium oxide ceramic tube carrier are blocked, and the thick Fe and Cu mesoporous material is smeared to the outer surface of the aluminium oxide ceramic tube carrier; rotary curing is carried out to obtain an even membrane layer; the ceramic tube membrane is dried in vacuum to obtain the Fe and Cu bi-metal loading mesoporous carbon and alumina composite ceramic membrane material. The composite ceramic membrane is used for degrading an ofloxacin solution which passes through the bi-metal loading layer, degradation time is the residencetime of the ofloxacin on the ceramic membrane, and the degradation rate of the ofloxacin in short time can be 90%.

Owner:TIANJIN POLYTECHNIC UNIV

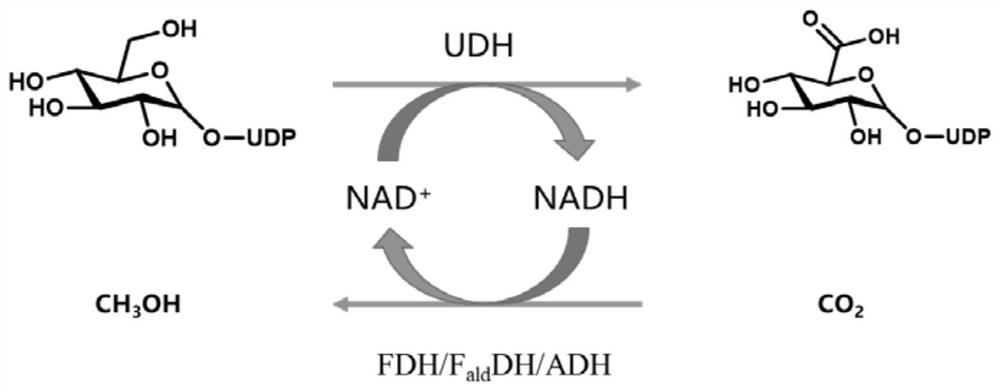

Metal organic framework multi-enzyme composite catalytic material, preparation method, and application and use method of metal organic framework multi-enzyme composite catalytic material

PendingCN113801873ASynthetic conditions are mildReduce inactivation denaturationOxidoreductasesOn/in organic carrierMetal-organic frameworkPhysical chemistry

The invention discloses a metal organic framework multi-enzyme composite catalytic material, a preparation method, and application and use method of the metal organic framework multi-enzyme composite catalytic material. The composite catalytic material comprises formate dehydrogenase, formaldehyde dehydrogenase, methanol dehydrogenase, UDP-glucose dehydrogenase and an MOF material, and is provided with a hollow capsule cavity; the formate dehydrogenase, the formaldehyde dehydrogenase and the methanol dehydrogenase are wrapped in the capsule cavity, and the UDP-glucose dehydrogenase is immobilized in the MOF material. According to the composite catalytic material of the invention, CO2 can be effectively recycled to provide a potential method for solving the greenhouse effect, repeated utilization can be implemented through immobilization and cyclic regeneration of cofactors while relatively high catalytic activity is kept, and a high-value industrial product is synthesized by a low-cost and environment-friendly method.

Owner:NANJING NORMAL UNIVERSITY

Recovery device and method for recovering uuv from usv water surface based on flexible arm

ActiveCN109911124BNo interface requirementPerformance is not affectedLifeboat handlingUnderwater vesselsControl cellMechanical engineering

The invention relates to a recovering device for recovering a UUV (underwater unmanned vehicle) on the water surface of a USV (unmanned surface vehicle) based on a flexible arm. The recovering deviceis characterized by comprising a recovering control module, an oil path control unit, a hydraulic oil filling device, a flexible capturing belt and a suspending swing arm device; the recovering control module is arranged in a cabin of the USV; one end of the suspending swing arm device is arranged on a deck on the USV, and the other end of the suspending swing arm device is connected with the hydraulic oil filling device; a rolling wheel is arranged in the center position of the hydraulic oil filling device; the flexible capturing belt is curled on the rolling wheel; the oil path control unitis arranged on the hydraulic oil filling device; the recovering control module is sequentially connected with the oil path control unit, the hydraulic oil filling device and the flexible capturing belt; and the recovering control module is connected with the suspending swing arm device. The recovering device has the following beneficial effects: the recovering method provided by the invention adopts a flexible arm technology, is suitable for recovering the revolved body type UUV, does not have any interface requirement on the UUV, avoids influence on the overall performance of the UUV and hasconcise recovering step.

Owner:HOHAI UNIV

A microwave synthesis method of 1,3-bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane

ActiveCN111269254BGood catalytic activity and stabilityLow costSilicon organic compoundsMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a microwave synthesis method of 1,3-bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane. Including: (1) Under the protection of inert gas, sequentially add tetramethyldisiloxane, organic solvent, 4-vinyl-1,2-epoxycyclohexene into the reaction flask and stir, and then add the supported Pt / Y molecular sieve catalyst, finally add absolute ethanol, continue to stir to obtain a suspension; (2) move the suspension into a microwave synthesis reactor for reaction, after the reaction, the reaction solution is decompressed to remove solvents and low boilers, and then centrifuged , to give 1,3-bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane. The invention has mild reaction conditions, short reaction time, high conversion rate of raw material active hydrogen, excellent activity and stability of the catalyst, recyclable reuse, reduced cost, high yield of the prepared target product, and good industrialization prospect.

Owner:CHANGZHOU HIGH TECH RES INST OF NANJING UNIV

Chiral catalyst in binaphthol synthesis technology

ActiveCN103480418BHigh feasibilityHigh optical purityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsImpurityCoordination complex

A chiral catalyst in a binaphthol synthesis technology is a 1,2-cyclohexanediamino-2-(3-hydroxy-2-naphthalenone)Schiff base-ferric iron complex, and the 1,2-cyclohexanediamino-2-(3-hydroxy-2-naphthalenone)Schiff base is generated through reacting (1R,2R) or (1S,2S)1,2-cyclohexanediamine with 3-hydroxy-2-naphthalenone. The structural formula of the chiral catalyst is shown in the specification. Cheap ferric iron same with the center ligand of the catalyst is adopted as an oxidant to carry out a chiral catalytic reaction, and the adoption metal ions as an oxidant can guarantee the high conversion rate of a product; the catalyst does not react with the oxidant to form impurities in a catalyst and oxidant recovery process, so a recovery step is simplified, and the recovery feasibility of the catalyst is improved; and the recycle of the catalyst and the oxidant can guarantee a high optical purity of the product, a high conversation rate and a high optical purity can be realized on the basis of a low cost, the pressure to the environmental protection is reduced, and the green chemistry is realized.

Owner:宿迁思睿屹新材料股份有限公司

Improved method for preparing pyrrolopyrrole-1,4-diketone derivative

ActiveCN103012409BSimplify recycling stepsReduce manufacturing costOrganic chemistryAzo dyesPotassiumKetone

The invention relates to a method for preparing a pyrrolopyrrole-1,4-diketone derivative (the pyrrolopyrrole-1,4-diketone derivative can be used for preparing organic pigments). The method includes the main step: a target object is obtained through the reaction of succinic acid dialkyl ester and a nitrile compound at a temperature of 60 DEG C-140 DEG C in a sodium tert-pentoxide or potassium / tert-amyl alcohol medium. The method is characterized in that firstly, the adopted succinic acid dialkyl ester is succinic acid di-tert amyl ester; and secondly, after the reaction of succinic acid ditertiary amyl ester and the nitrile compound is stopped, the obtained mixture is heated and dried at the vacuum degree of 1-2 mmHg, the escaped tert-amyl alcohol is recovered at the same time, after heating and drying, the mixture heated and dried is transferred to a hydrolyzing reactor and diluted by carbinol / water, the generated sodium hydroxide is neutralized through inorganic acid, and the target object is obtained through liquid / solid separation. According to the invention, the steps for tert-amyl alcohol recovery are simplified, further, the cost in preparing the pyrrolopyrrole-1,4-diketone derivative is reduced.

Owner:辽宁鸿港化工有限公司 +2

A method for separating positive and negative poles and separators of lifepo4 batteries

ActiveCN103474720BAvoid harmEasy to separateWaste accumulators reclaimingBattery recyclingOrganic solventMechanical crushing

A method for separating the positive and negative electrodes and diaphragms of LiFePO4 batteries: a. Mechanically crush the batteries (including the mixture of positive and negative electrodes and diaphragms) of LiFePO4 batteries that have been removed from the shell into fragments with a size of 1cm2~100cm2; b. The feeder evenly feeds the above-mentioned fragments to the conveyor belt, and the fragments are flattened on the conveyor belt and advance at a constant speed. By setting a magnet above the conveyor belt, or using a magnetic roller, the magnetic positive electrode material is separated from the negative electrode material and the diaphragm; c. After immersing the negative electrode and diaphragm material obtained after separating the positive electrode into water, collect the diaphragm material floating on the upper layer, and salvage and collect the negative electrode material sinking at the bottom, so as to realize the separation of the negative electrode and the diaphragm. The invention can conveniently and efficiently realize the separation of the positive electrode, the negative electrode and the diaphragm of a large-scale LiFePO4 battery, and avoids possible harm to the environment caused by methods such as the use of organic solvents and high-temperature heating.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

Method for Comprehensive Recovery of Phosphorus and Rare Earth from Monazite-containing Rare Earth Phosphate Rock

ActiveCN105331812BHigh recovery rateEfficient separationProcess efficiency improvementRaw phosphate material treatmentSolubilityFiltration

The invention discloses a method for comprehensively recycling phosphorus and rare earth from rare earth phosphorite containing monazite. The method includes the following steps that rare earth phosphorite containing monazite is obtained from phosphoric acid in a leaching manner, and a monocalcium phosphate solution containing rare earth and slag containing monazite are obtained through filtration; the monocalcium phosphate solution containing rare earth is processed through a precipitation method, dissolved rare earth precipitates, a monocalcium phosphate solution and rare earth slag containing phosphoric acid are obtained through filtration, and the rare earth slag containing phosphoric acid and slag containing monazite are mixed to form mixed slag; and phosphorus in the monocalcium phosphate solution is recycled, and rare earth in the mixed slag is recycled. Acid leaching is conducted by adding phosphoric acid, phosphorus in rare earth phosphorite containing monazite forms monocalcium phosphate high in solubility, and therefore monazite existing in a precipitation manner and phosphorus can be separated. Then, the monocalcium phosphate solution containing rare earth is processed through the precipitation method, and rare earth and phosphorus elements in phosphorite can be effectively separated. Rare earth and phosphorus are effectively separated through two times of separation steps, and therefore the rare earth recycling rate is increased.

Owner:GRIREM ADVANCED MATERIALS CO LTD

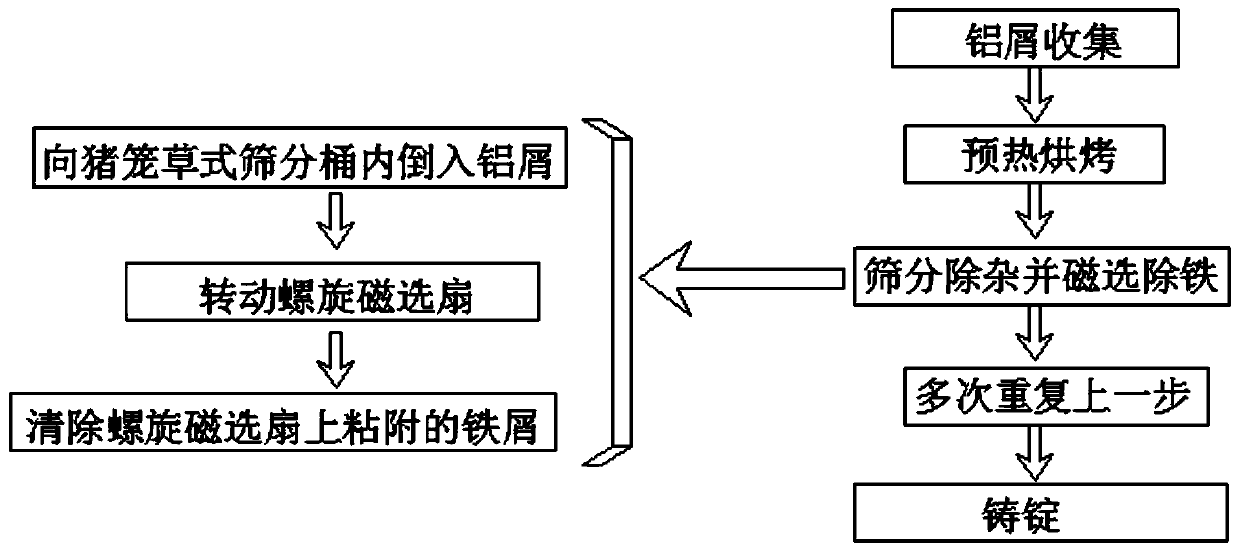

Nepenthes type aluminum scrap recycling treatment process

The invention discloses a nepenthes type aluminum scrap recycling treatment process, and belongs to the field of metal waste recovery. The nepenthes type aluminum scrap recycling treatment process hasthe beneficial effects that the two steps of screening and impurity removal, and magnetic separation and iron removal are combined in one step through the use of a nepenthes type screening barrel, sothat the aluminum scrap recovery process is simplified, and the time of the aluminum scrap recycling treatment is saved to a great extent, and the efficiency of the aluminum scrap recycling treatmentis remarkably improved; meanwhile, nepenthes type special-shaped sleeve pipes in screening holes are used so as to enable the probability that aluminum scraps are gotten stuck in the screening holesto be reduced, and the service life of a screen is prolonged; and meanwhile, nano-scale micropores of the nepenthes type special-shaped sleeve pipes and lubricating oil inside the nepenthes type special-shaped sleeve pipes are used, so that the aluminum scraps gotten stuck in the screening holes are just like insects preyed by nepenthes and are very difficult to stay in the screening holes; and even if the aluminum scraps are gotten stuck, when the aluminum scraps are taken out, the screen can be effectively protected due to the reduction of the friction, so that the probability that the screen is damaged by the aluminum scraps is reduced, and the cost investment of the aluminum scrap treatment is reduced.

Owner:宁波锦锐能源科技有限公司

Method for recovering metal rubidium resources in pyrrhotite tailings

InactiveCN111974553ASimplify recycling stepsHigh recovery rateFlotationMagnetic separationRubidium compoundSodium acid carbonate

The invention discloses a method for recovering metal rubidium resources in pyrrhotite tailings. The method comprises the following steps: (1) crushing tailings, and carrying out superconducting magnetic separation; (2) preparing ore pulp from the magnetic separation tailings in the step (1), adding sodium carbonate, fully stirring, adding a flotation agent, and carrying out air flotation; and (3)enabling sulfuric acid to be added into the tailings, after full stirring, enabling a flotation agent to be added for air flotation, and obtaining rubidium concentrate with the relatively high grade.Compared with the prior art, the method has the advantages that the recovery step of the metal rubidium in the tailings is simplified, meanwhile, the recovery rate of the rubidium is improved, and arelatively good preposition step is provided for further industrial purification of the rubidium or the rubidium-containing compound.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A high-efficiency organic piston ring carbon removal and repair agent

ActiveCN111925844BImprove securityStrong wrappingLiquid carbonaceous fuelsFuel additivesCombustion chamberActive agent

The invention proposes an organic piston ring carbon removal repair agent, which is characterized in that it includes the following components in parts by mass: 50-80 parts of carbon deposit dissolving agent, 5-20 parts of cleaning dispersant, and ester type lubricating tackifier 1-5 parts, 1-10 parts of solvent-based surfactant, 1-2 parts of oil disintegration accelerator, and 0.1-1 part of additives. The organic piston ring carbon removal and repair agent of the present invention can effectively remove carbon deposits in combustion chambers such as cylinder heads, piston crowns, and piston ring grooves, clean and release piston rings, restore piston ring elasticity and cylinder pressure, and make stuck piston rings Get restored. Eliminate the resulting problems such as knocking, poor heat dissipation, insufficient cylinder pressure, and high oil consumption.

Owner:杭州维客泰美品牌管理有限公司

Process for recovering sugar liquor in preserved fruit production

InactiveCN111955584ASimplify recycling stepsLow impurity contentConfectioneryAnion exchangersActivated carbonAlcohol

The invention discloses a process for recovering sugar liquor in preserved fruit production. the process comprises the following steps of (1) filtering sugar liquor to be treated to remove suspended matters, and adding complex enzyme for full reaction; (2) adding citric acid into the sugar liquor obtained in the step (1), and regulating the pH value of the sugar liquor; (3) adding an absolute ethyl alcohol solution, fully stirring and standing; (4) filtering the sugar liquor after standing, and then heating the sugar liquor; (5) adding activated carbon into the heated sugar liquor, fully and uniformly mixing and filtering, and (6) enabling the sugar liquor in the step (5) to pass through an ion exchange column to obtain recovered sugar liquor. Compared with the prior art, according to thescheme, the sugar liquor can be recycled within a reasonable cost range, and therefore the sugar liquor can be repeatedly used. Therefore, the purpose of fully utilizing raw material resources is achieved, and the method has highly important significance.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

A kind of modified hydroxypropyl methylcellulose for reinforced tile adhesive and its preparation method and application

ActiveCN111732911BImprove product qualityQuality improvementStarch derivtive adhesivesMacromolecular adhesive additivesAdhesiveMethyl cellulose

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

A kind of recycling method for lifepo4 battery positive electrode

ActiveCN103474719BImprove resource utilizationAvoid harmWaste accumulators reclaimingBattery recyclingAdhesiveElectrical battery

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

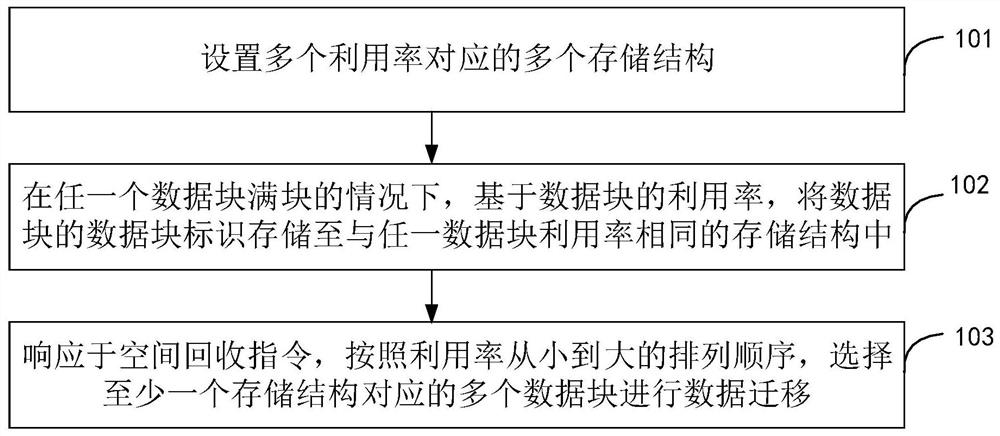

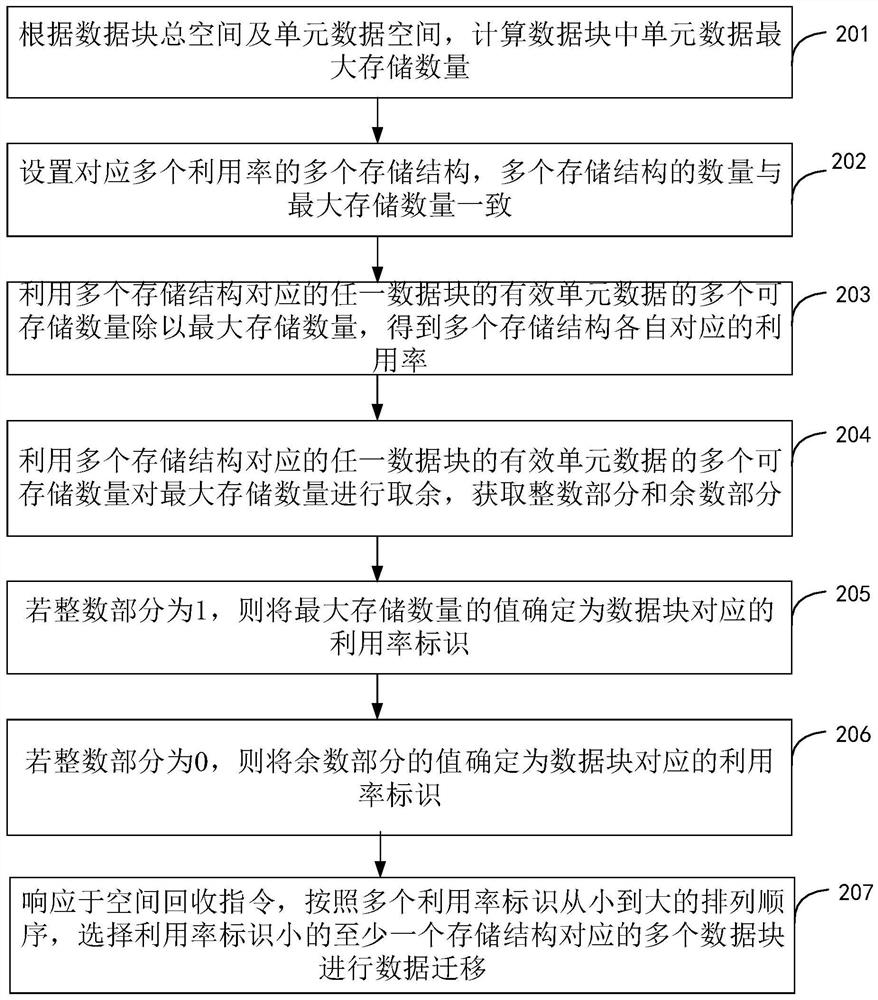

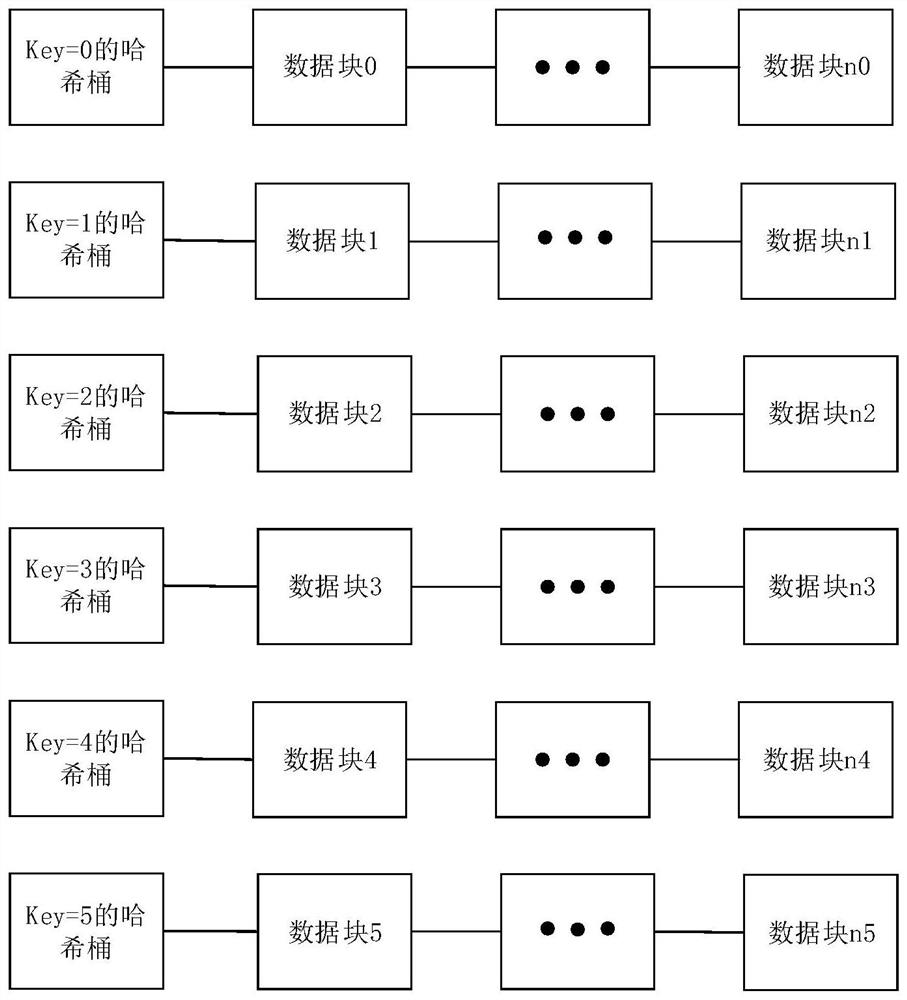

Space recovery method, device and equipment

PendingCN113687774ASimplify recycling stepsImprove recycling efficiencyInput/output to record carriersProcess engineeringUtilization rate

The embodiment of the invention provides a space recovery method, device and equipment. A plurality of storage structures corresponding to different utilization rates are set; when data is written into any data block in a plurality of data blocks in the storage system, the utilization rate of the data block is calculated, and the data block identifier of the data block is stored in the corresponding storage structure based on the utilization rate when the data block is full; and in response to the space recovery instruction, a plurality of data blocks corresponding to the at least one storage structure are selected to perform data migration according to the arrangement sequence of the utilization rates from small to large. According to the technical scheme provided by the embodiment of the invention, the recovery efficiency of the storage system in the space recovery process can be effectively improved.

Owner:RUIJIE NETWORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![A microwave synthesis method of 1,3-bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane A microwave synthesis method of 1,3-bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane](https://images-eureka.patsnap.com/patent_img/0dd218bb-af1d-430b-9fd8-499626a95733/HDA0002388507010000011.png)

![A microwave synthesis method of 1,3-bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane A microwave synthesis method of 1,3-bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane](https://images-eureka.patsnap.com/patent_img/0dd218bb-af1d-430b-9fd8-499626a95733/HDA0002388507010000012.png)

![A microwave synthesis method of 1,3-bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane A microwave synthesis method of 1,3-bis[2-(3,4-epoxycyclohexyl)ethyl]tetramethyldisiloxane](https://images-eureka.patsnap.com/patent_img/0dd218bb-af1d-430b-9fd8-499626a95733/BDA0002388506000000071.png)