Comprehensive recycling method of waste plasma screen

A plasma screen and waste technology, applied in the field of comprehensive recycling of ion screens, can solve the problems of lack of comprehensive utilization and recycling, achieve simplified steps, improve efficiency, and solve the effect of easy bonding when encountering water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

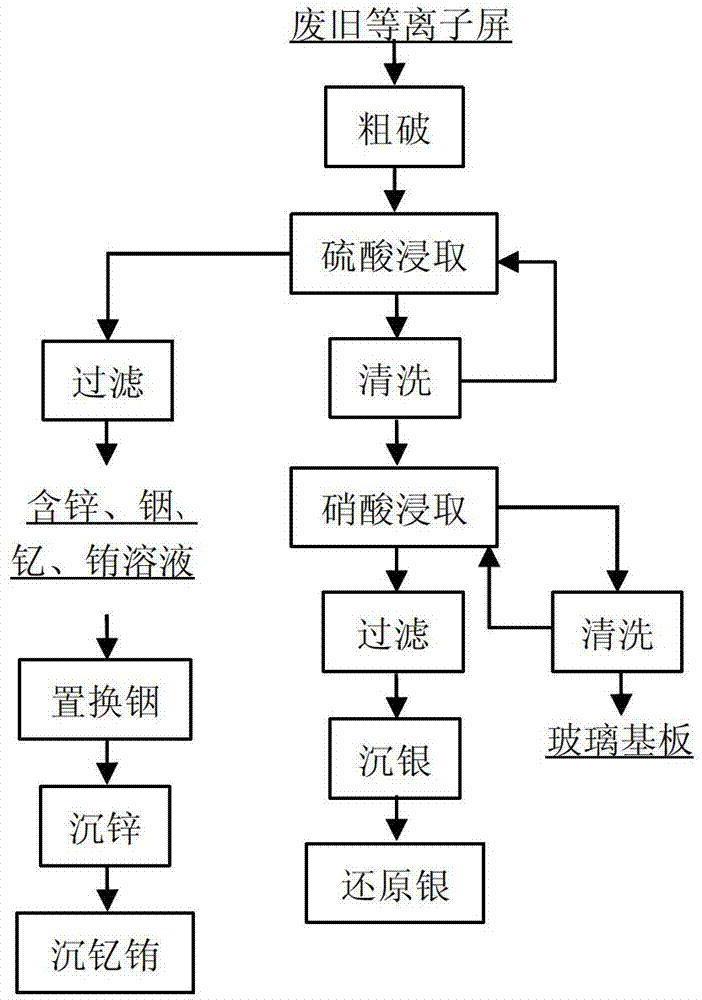

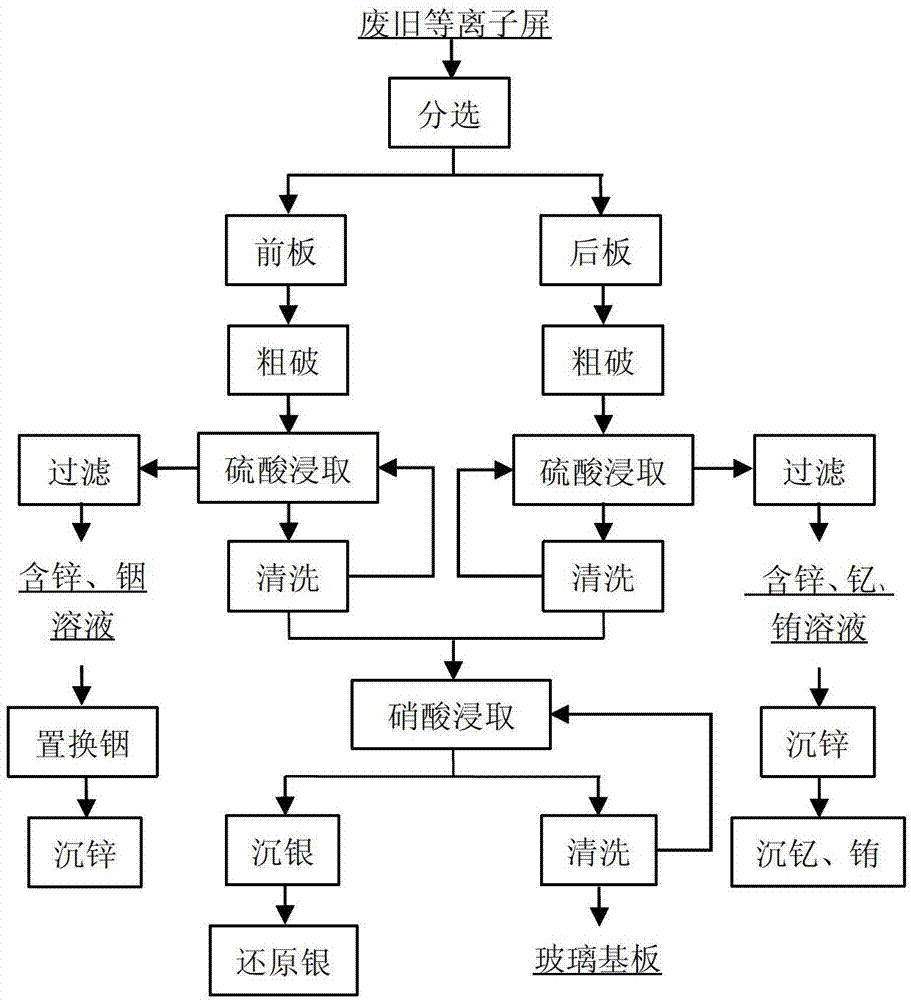

Method used

Image

Examples

Embodiment 1

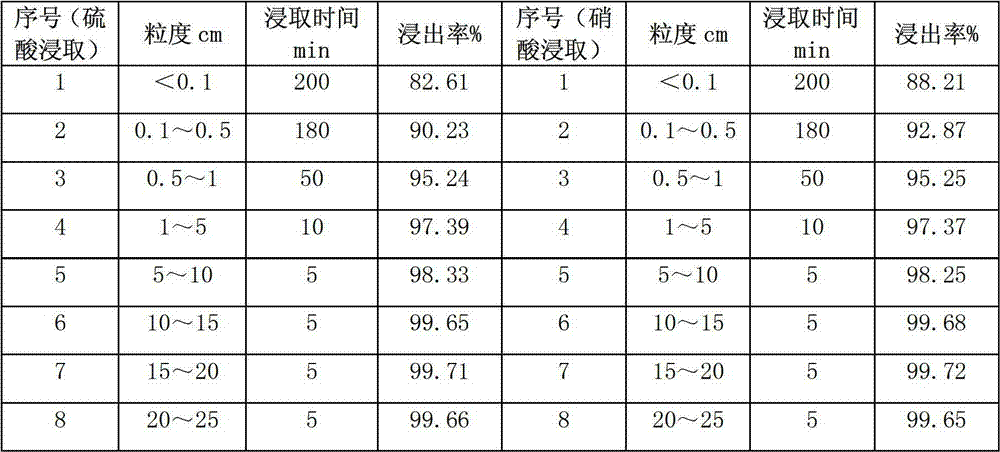

[0040] Embodiment 1 sulfuric acid and nitric acid leaching experiment of the present invention

[0041]In this example, the mixture of the front panel and the rear panel of the waste plasma screen is crushed or even finely ground to obtain waste plasma screens with different particle sizes (maximum distance between any two points) as shown in Table 1, and then the mass Sulfuric acid and nitric acid with a percentage concentration of 20% were used for leaching. Ultrasonic activation treatment and stirring were performed during leaching. The ultrasonic vibrator was closed at the bottom of the leaching tank, and the ultrasonic frequency was about 40kHz. The leaching rate was finally tested. The results are shown in Table 1. Among them, the leaching rate of sulfuric acid refers to the ratio of the total amount of indium, zinc, yttrium and europium leached to the total amount of indium, zinc, yttrium and europium contained in waste plasma screens, and the leaching rate of nitric aci...

Embodiment 2

[0047] Embodiment 2 The present invention directly reclaims silver, yttrium, europium, zinc and indium with nitric acid leaching

[0048] In this example, 50 kg of the mixture of the waste plasma screen front panel and rear panel were weighed and coarsely crushed to obtain 18.1 kg with a particle size (maximum distance between any two points) of 5 to 10 cm, 20.6 kg with a particle size of 10 to 15 cm, and 15 16.7kg for 20-20cm, 23.4kg for 20-25cm, 21.2kg for 25-30cm. It contains 150.1g of silver, 90.2g of yttrium, 20.0g of europium, 802.1g of zinc and 10.3g of indium. The 100kg waste plasma screen front panel and rear panel come from the same batch of production waste, the raw material is stable, and the content of each element is also stable.

[0049] Use 2L of nitric acid with a mass percentage concentration of 15% for leaching in batches, leaching for 5 minutes each time, ultrasonic activation and stirring during leaching, the ultrasonic vibrator is closed on the side wall...

Embodiment 3

[0050] Embodiment 3 The present invention directly reclaims silver, yttrium, europium, zinc and indium with sulfuric acid and nitric acid leaching

[0051] In this example, 50 kg of the mixture of the waste plasma screen front panel and rear panel were weighed and coarsely crushed to obtain 17.9 kg with a particle size (maximum distance between any two points) of 5 to 10 cm, 23.4 kg with a particle size of 10 to 15 cm, and 15 17.6kg for ~20cm, 21.4kg for 20~25cm, 19.7kg for 25~30cm. It contains 150.1g of silver, 90.2g of yttrium, 20.0g of europium, 802.1g of zinc and 10.3g of indium. 100kg of waste plasma screen front panel and rear panel come from the same batch of production waste, the raw material is stable, and the content of each element is stable.

[0052] Use 2L of sulfuric acid with a mass percentage concentration of 15% for leaching in batches, leaching for 10 minutes each time, and perform ultrasonic activation and stirring during leaching. The ultrasonic vibrator i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com