Metal organic framework multi-enzyme composite catalytic material, preparation method, and application and use method of metal organic framework multi-enzyme composite catalytic material

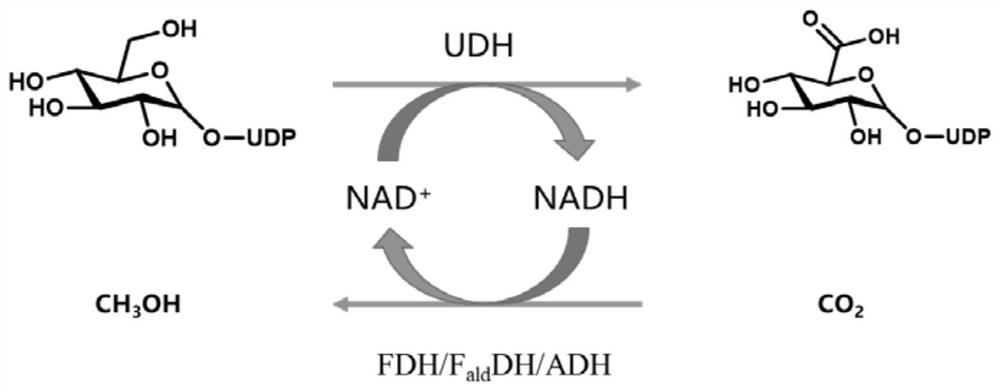

A technology of metal-organic frameworks and catalytic materials, applied in biochemical equipment and methods, fixed on/in organic carriers, enzymes, etc., can solve the problems of difficult repeated use and difficult collection of enzymes for repeated use , to achieve the effect of improving the recycling rate, mild synthesis conditions and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] FDH / F ald Preparation of DH / ADH@ZPF:

[0054] First set FDH, F ald DH, ADH (FDH, F aldThe concentrations of DH and ADH are both 0.3mg / mL) into Tris-HCl buffer (pH=7, 0.1M), then add 2-hydroxy-5-fluoropyrimidine (0.2M), and finally add zinc nitrate (0.05M) and stir After uniformity, react at 35°C for 12h. After the reaction, centrifuge at 8000rpm for 4min to recover the precipitate. It was then washed with ultrapure water, sonicated and centrifuged three times to remove free enzyme not encapsulated by the ZPF material.

Embodiment 2

[0056] (FDH / F ald Preparation of DH / ADH@ZPF) / UGDH@MOF:

[0057] 1. (FDH / F ald DH / ADH@ZPF) / UGDH@ZIF-8

[0058] Take the prepared 0.3mg FDH / F ald DH / ADH@ZPFs powder was added to 1mL Tris-HCl buffer solution, stirred evenly, added to 2-methyl-imidazole (HmIm, 640mM) solution, and then added Zn(NO 3 ) 2 ·6H 2 O (40mM) solution and add ultrapure water to make up to 3mL. React at 37° C. and 300 rpm for 24 hours. After the reaction, centrifuge at 8,000 rpm for 4 minutes to recover the precipitate. It was then washed with ultrapure water, sonicated and centrifuged three times.

[0059] 2. (FDH / F ald DH / ADH@ZPF) / UGDH@ZIF-90

[0060] Take the prepared 0.3mg FDH / F ald DH / ADH@ZPFs powder was added to 1mL Tris-HCl buffer solution, stirred evenly, added to 2-imidazole-carboxaldehyde (HICA, 160mM) solution, and then added Zn(NO 3 ) 2 ·6H 2 O (40mM) solution and add ultrapure water to make up to 3mL. React at 37° C. and 200 rpm for 24 hours. After the reaction, centrifuge at 8...

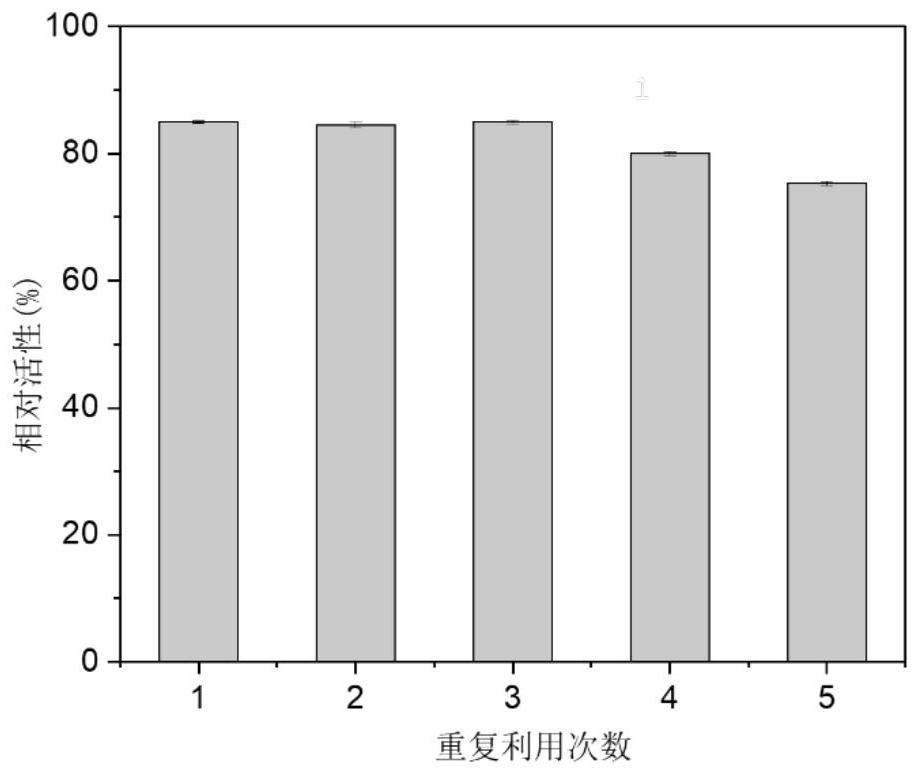

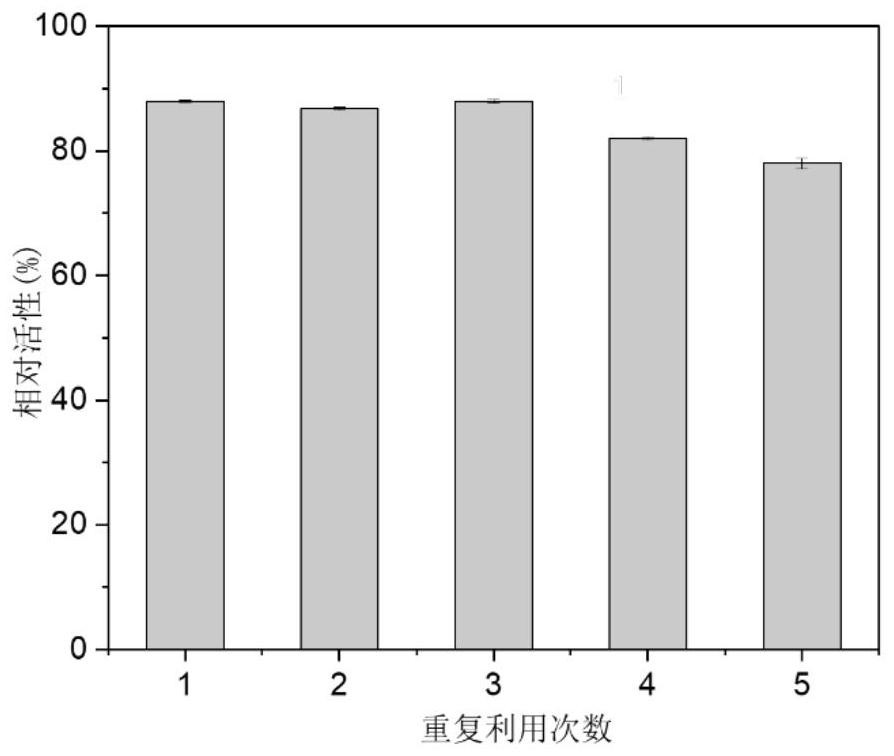

Embodiment 3

[0064] Etching of Template ZPF and FDH / F ald Preparation of DH / ADH / UGDH@MOF:

[0065] Will prepare (FDH / F ald DH / ADH@ZPF) / UGDH@MOF powder was added to PB (pH=5, 50mM) buffer solution and stirred, centrifuged (8000rpm, 5min) after 0.5h, washed, and dried at 35°C to obtain a solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com