Chiral catalyst in binaphthol synthesis technology

A technology of chiral catalyst and synthesis process, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, organic compound preparation, etc. Industrial applicability, affecting product performance and other issues, to achieve the effect of simplifying recycling steps, low cost, and improving feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

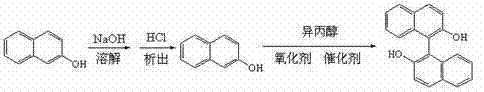

Method used

Image

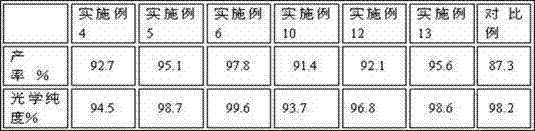

Examples

Embodiment 1

[0037] This example provides a preparation method of a chiral catalyst, which is realized through the following steps: dissolve 5.0g (1R,2R)1,2-cyclohexanediamine in 50mL of chloroform, ice bath, and then slowly drop 15.0g3-hydroxyl-2-naphthone, after reacting 12 hours, purify with silica gel column (mobile phase is : =1:1.5), to obtain 15.64g of yellow solid, dissolve the solid in 200mL of methanol, add 7.5g of ferric chloride, stir at room temperature for 3 hours, spin off the solvent, and recrystallize with n-hexane to obtain 19.14g of chiral catalyst a .

Embodiment 2

[0039] This example provides a preparation method of a chiral catalyst, which is realized through the following steps: dissolve 5.5g (1R,2R)1,2-cyclohexanediamine in 50mL of chloroform, ice-bath, and then slowly drop 18.0g3-hydroxyl-2-naphthone, after reacting for 18 hours, purify with silica gel column (mobile phase is : =1:1.5), to obtain 16.85 g of yellow solid, dissolve the solid in 250 mL of methanol, add 8.5 g of ferric chloride, stir at room temperature for 4.5 hours, spin off the solvent, and recrystallize with n-hexane to obtain 20.25 g of chiral catalyst b .

Embodiment 3

[0041] This example provides a preparation method of a chiral catalyst, which is realized by the following steps: dissolve 4.5g (1S,2S)1,2-cyclohexanediamine in 50mL of chloroform, ice-bath, and then slowly drop 14.0g3-hydroxyl-2-naphthone, reacted after 10 hours, purified with silica gel column (mobile phase is : =1:1.5), to obtain 13.57g of yellow solid, dissolve the solid in 180mL of methanol, add 7.0g of ferric chloride, stir at room temperature for 3 hours, spin off the solvent, and recrystallize with n-hexane to obtain 17.02g of chiral catalyst c .

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com