A kind of recycling method for lifepo4 battery positive electrode

A recycling method and battery positive electrode technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems affecting the recovery rate and the purity of recycled products, high energy consumption, environmental pollution, etc., and achieve a thorough leaching effect. Effect of Simplified Recycling Steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

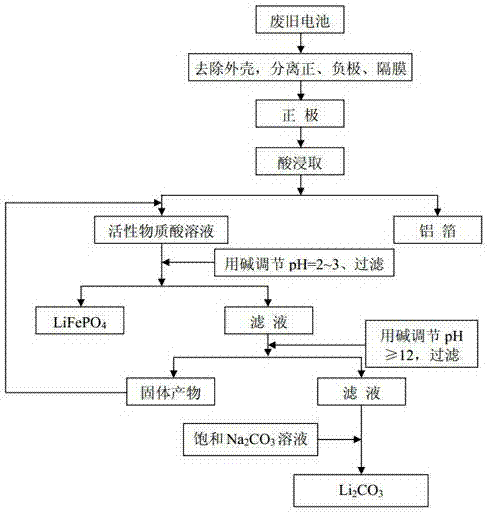

Method used

Image

Examples

Embodiment 1

[0020] One for LiFePO 4 The recycling method of battery positive electrode comprises the following steps:

[0021] a. LiFePO with an aluminum-plastic soft package 4 Remove the shell after the battery (capacity 20Ah, voltage 3.2V) is discharged, and separate the positive, negative and diaphragm;

[0022] b. Completely immerse about 270g of the positive plate in 540mL of hydrochloric acid solution with a concentration of 1% by mass, soak for 10min, take out the aluminum foil current collector, rinse with water until there is no acid residue on the surface, weigh 40g after air drying, and the recovery rate is 96.1%;

[0023] c. Add 183.4mL concentrated hydrochloric acid (36.5% mass concentration) to the solution obtained in step b to adjust the mass concentration of hydrochloric acid in the solution to 10%, heat to 80°C, react for 5h, and then filter to remove the conductive agent and binder ;

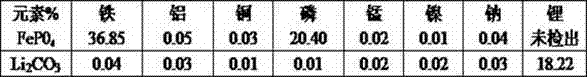

[0024] d. Add concentrated ammonia water to the filtrate obtained in step c, adjus...

Embodiment 2

[0030] One for LiFePO 4 The recycling method of battery positive electrode comprises the following steps:

[0031] a. Put 2 aluminum shells LiFePO 4 Remove the shell after the battery (capacity 15Ah, voltage 3.2V) is discharged, and separate the positive, negative and diaphragm;

[0032] b. Completely immerse about 600g of the positive plate in 1.8L of sulfuric acid solution with a concentration of 4% by mass, soak for 5min, take out the aluminum foil current collector, rinse with water until there is no acid residue on the surface, weigh 87.6g after air drying, and the recovery rate is 96.8%;

[0033] c. Add 370 mL of concentrated sulfuric acid (98% mass concentration) to the solution obtained in step b, adjust the mass concentration of sulfuric acid in the solution to 20%, heat to 90°C, react for 2 hours, and filter to remove the conductive agent and binder;

[0034] d. Add solid sodium hydroxide to the filtrate obtained in step c, adjust the pH of the solution to 2.5, hea...

Embodiment 3

[0039] One for LiFePO 4 The recycling method of battery positive electrode comprises the following steps:

[0040] a. Put 4 steel shell LiFePO 4Remove the casing after the battery (capacity 18Ah, voltage 3.2V) is discharged, and separate the positive, negative and diaphragm;

[0041] b. Completely immerse about 1.3kg of the positive plate in 5.2L of sulfuric acid solution with a mass percentage concentration of 8%, soak for 10min, take out the aluminum foil current collector, rinse with water until there is no acid residue on the surface, weigh 202.8g after air drying, and the recovery rate is 97.5% ;

[0042] c. Add 1.6L concentrated sulfuric acid (98% mass concentration) to the solution obtained in step b to adjust the mass concentration of sulfuric acid in the solution to 30%, heat to 100°C, react for 1 hour, and filter to remove the conductive agent and binder;

[0043] d. Add solid potassium hydroxide to the filtrate obtained in step c, adjust the pH of the solution to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com